Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Wiring Harness Machine

Who are we?

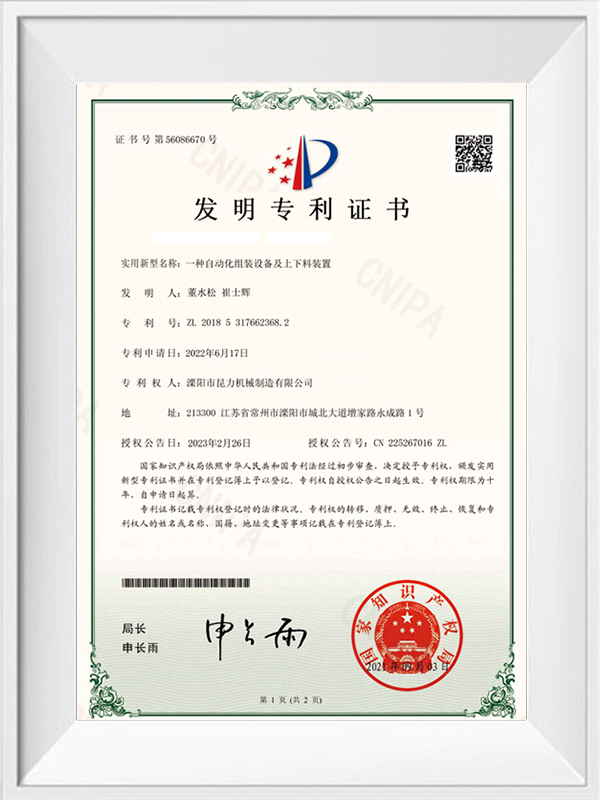

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Wiring Harness Machine Suppliers and Wiring Harness Machine Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

For the training and optimization of machine learning algorithms, how can wire harness machine manufacturers ensure the quality and accuracy of wire harness machine data?

Data collection and processing:

Collect high-quality wire harness machine production data, including sensor data, process parameters, test results, etc.

Preprocess the collected data, including data cleaning, denoising, standardization, etc., to eliminate outliers and noise in the data and improve data quality.

Data partitioning:

Divide the data set into training set, validation set and test set. The training set is used to train the machine learning model, the validation set is used to evaluate the model performance and adjust the hyperparameters, and the test set is used to finally evaluate the generalization ability of the model.

Model selection and training:

Select appropriate machine learning algorithms and model structures, such as neural networks, decision trees, support vector machines, etc.

Use the training set to train the model and optimize the performance of the model by adjusting the hyperparameters (such as learning rate, number of iterations, hidden layer dimension, etc.).

Regularization and cross-validation:

Add regularization terms such as L1 or L2 regularization, Dropout, etc. during model training to prevent overfitting and improve the generalization ability of the model.

Use cross-validation techniques to evaluate the performance of the model by dividing the data set into multiple subsets, training and validating the model on each subset, and finally taking the average as the model performance indicator.

Data quality monitoring:

Perform quality checks on the collected data regularly to ensure the accuracy and completeness of the data.

Continuously monitor the data to promptly detect and deal with outliers and noise in the data.

Apply quality data management system:

Establish a quality data management system to record the production process of the wire harness machine and its process conditions, electrical performance and test results.

By analyzing the data in the quality data management system, timely discover problems in the production process and take corresponding measures to improve them.

What unique designs or technologies do wire harness machine suppliers have for wire harness machines in adapting to different wire types and specifications?

Multi-axis pay-off rack: Wire harness machines are often equipped with multi-axis pay-off racks that can handle multiple wires at the same time to meet the needs of different wire specifications. This design allows users to handle multiple wires in one operation, improving production efficiency and flexibility.

Advanced traction drive system: High-speed gearbox and dual active and dual traction devices are used to ensure the stability and uniformity of the wire during transmission. This design can handle long-length and large-section wires, such as aluminum/aluminum alloy wire, bare copper wire, etc.

Natural wire splitting and arranging system: Through natural wire splitting and arranging, the wire core is prevented from being scratched during the wire splitting process, ensuring the integrity of the wire. This is especially important for the production of high-pressure cross-linked cables.

Wire break parking device: The wire harness machine is equipped with an advanced wire break parking device, which can directly control each wire reel. When any wire reel breaks, the host can automatically stop in an emergency to ensure production safety.

Digital automatic frequency tracking technology: Some high-end wire harness machine suppliers use digital automatic frequency tracking technology to ensure that the equipment can accurately control the frequency when welding or processing wires, improve processing accuracy and product quality.

Flexible mold design: In order to meet the crimping requirements of different wires, wire harness machines are often equipped with replaceable mold designs. Users can choose the appropriate mold for crimping operations according to the specifications and types of wires.

Intelligent control system: Modern wire harness machines are often equipped with intelligent control systems, which can monitor the equipment operation status, wire processing status, etc. in real time, and automatically adjust and optimize according to actual conditions. This design improves the intelligence level and production efficiency of the equipment.

Modular design: The modular design makes the wire harness machine easy to maintain and upgrade. When a module fails or needs to be upgraded, the user can quickly replace or upgrade the module without affecting the operation of the entire equipment.

English

English русский

русский عربى

عربى