Silicon Carbide Grinding Equipment: Unlocking the Core Code for Precision Machining of Third-Generation Semiconductors

Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has become an essential material for new energy vehicles, 5G communications, photovoltaic power generation, and other fields, thanks to its excellent high-temperature resistance, high breakdown electric field, and high thermal conductivity. However, SiC is a typically hard and brittle material, with a Mohs hardness of 9.2, second only to diamond. Its processing demands extreme precision, stability, and efficiency. As a critical step in the SiC device fabrication process, grinding directly impacts material utilization, device performance, and production costs. Silicon carbide grinding equipment provides the core support for this process, and its technological level directly determines the speed and quality of the SiC industry's development.

Technical Barriers of Silicon Carbide Grinding Equipment: The Leap from "Hard and Brittle" to "Precision"

The core challenge of SiC grinding lies in balancing machining accuracy and efficiency. Unlike traditional metal materials, silicon carbide is prone to defects such as cracks and chipping during the grinding process. These defects not only lead to material scrapping but can also impact the reliability of subsequent devices. Therefore, silicon carbide grinding equipment must possess precise feed control, stable grinding force output, and efficient heat dissipation.

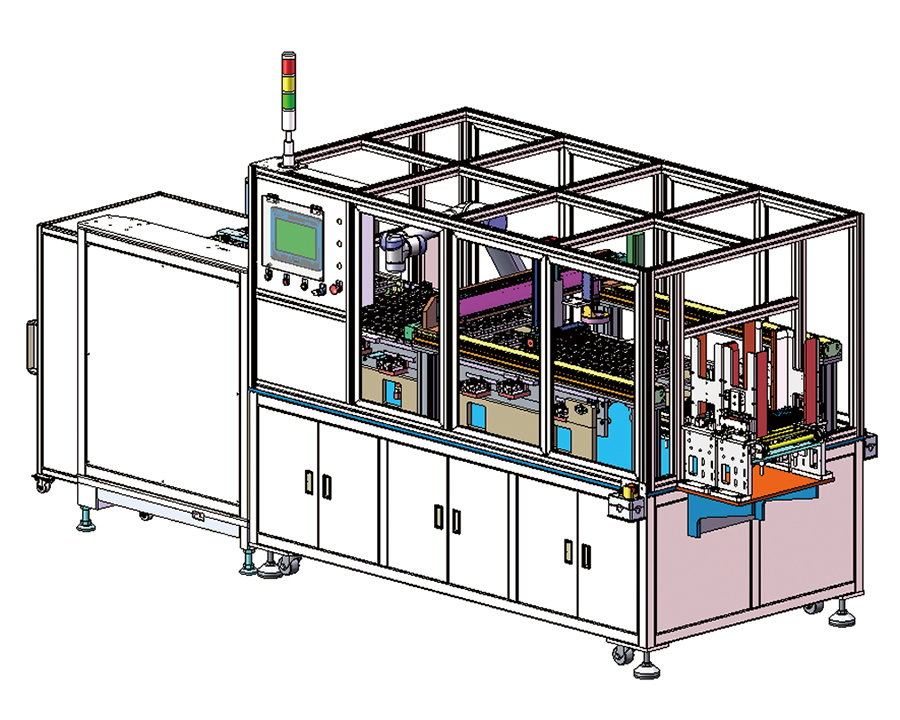

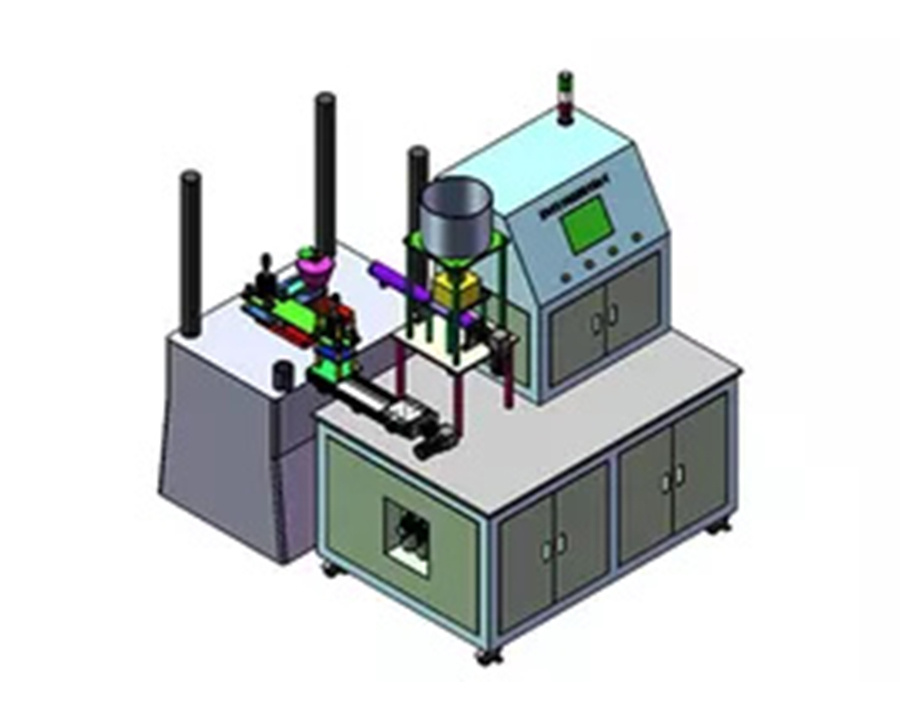

From a structural perspective, the high-precision spindle system is the "heart" of silicon carbide grinding equipment. To achieve nanometer-level machining accuracy, the spindle must utilize aerostatic or hydrostatic technology, coupled with a high-rigidity bearing design, ensuring extremely low radial and axial runout even at high rotation speeds. Furthermore, the equipment's guide rail system must offer backlash-free transmission characteristics, typically using a direct linear motor drive to avoid the mechanical hysteresis associated with traditional ball screws, thereby achieving micron-level feed accuracy control.

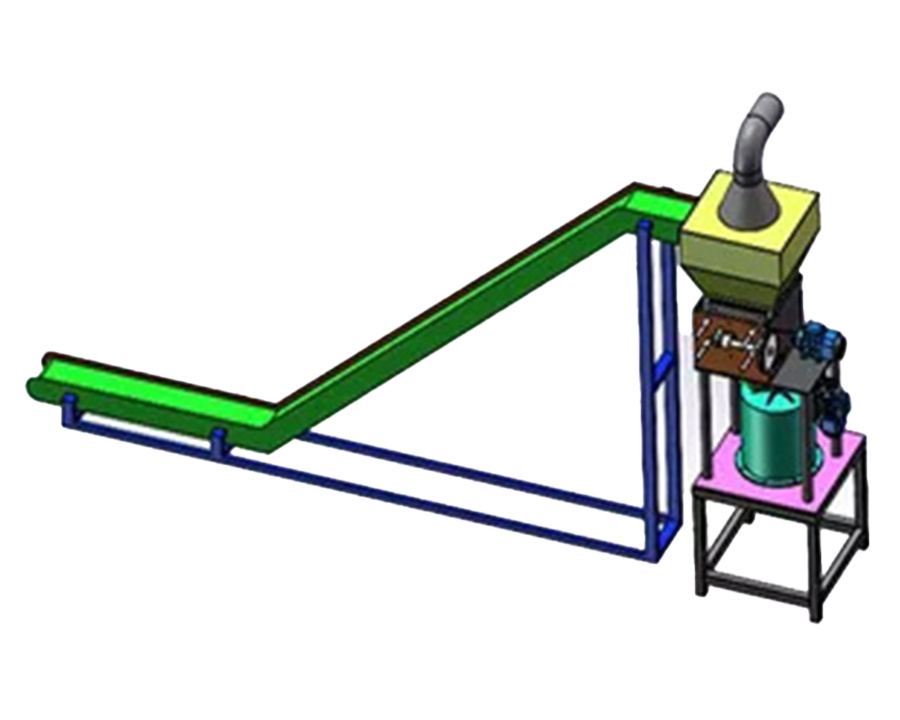

The selection and supply system of the grinding fluid are also critical technical issues. Silicon carbide grinding generates significant heat. Failure to dissipate heat promptly can lead to thermal deformation of the workpiece and accelerated wear of the grinding tool. Advanced silicon carbide grinding equipment is typically equipped with a multi-channel constant-temperature cooling system. By precisely controlling the temperature, flow rate, and spray angle of the grinding fluid, this system effectively removes heat and promptly flushes away grinding debris, preventing secondary scratches on the workpiece surface.

Silicon carbide grinding equipment selection: Matching the application scenario with the needs

In the field of silicon carbide substrate processing, the grinding equipment requirements for substrates of different sizes (such as 4-inch, 6-inch, and 8-inch) vary significantly. Large-sized substrates place greater emphasis on equipment stability and consistency to reduce warping caused by uneven stress distribution. Small-sized substrates, on the other hand, place greater emphasis on processing efficiency and edge quality control to avoid edge cracking that can affect subsequent epitaxial growth processes. Therefore, when selecting a grinding equipment, it is important to first clarify the dimensions of the workpiece and ensure that the equipment's travel range, worktable load capacity, and other parameters are compatible with the workpiece.

From a processing perspective, silicon carbide grinding can be divided into three stages: rough grinding, fine grinding, and superfine grinding. Each stage places varying emphasis on equipment performance. The rough grinding stage primarily aims to remove excess material, requiring equipment with high grinding power and a high feed rate. The fine grinding stage focuses on surface roughness and flatness, requiring higher motion precision and more stable grinding force control. The ultra-fine grinding stage aims to further reduce the depth of the surface damage layer, laying the foundation for subsequent polishing processes. During this stage, detailed specifications such as vibration control and ambient temperature stability are particularly critical.

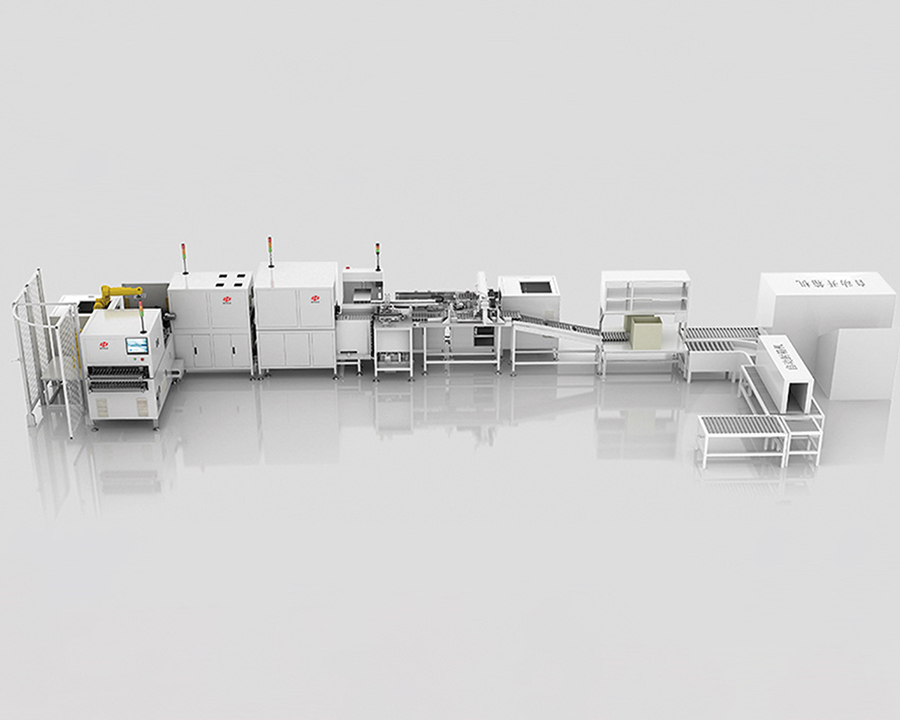

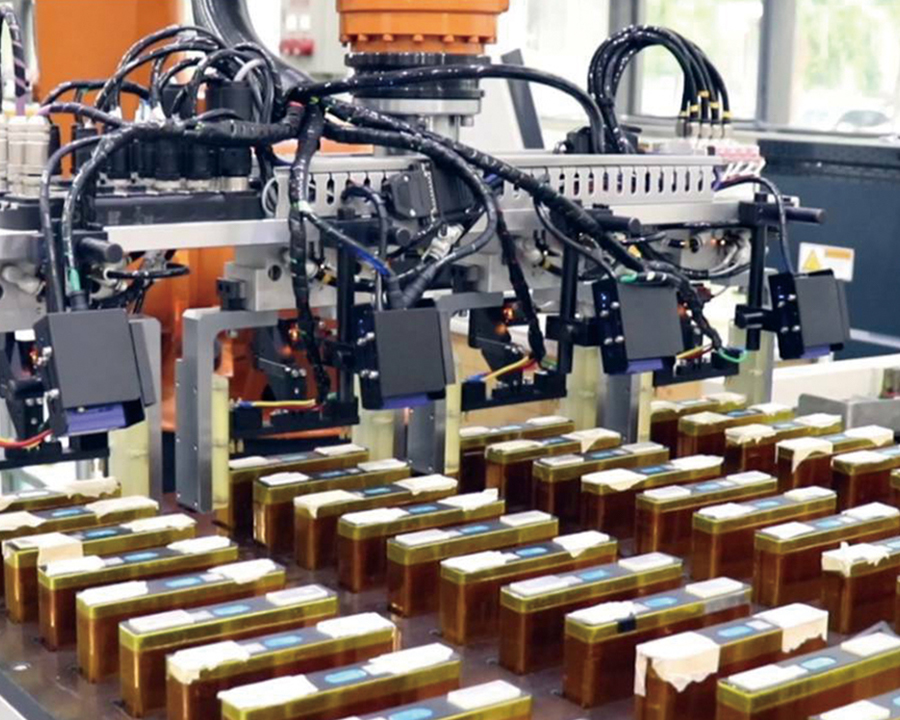

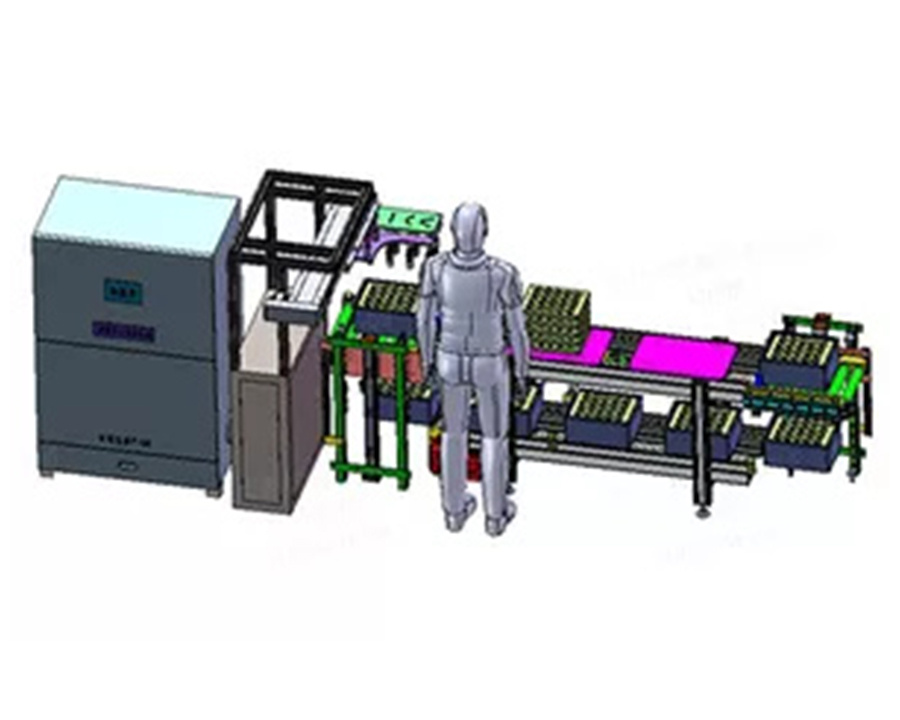

The degree of automation is also a key consideration when selecting a suitable grinding machine. As the silicon carbide industry moves towards large-scale mass production, the automation integration capabilities of the equipment directly impact production efficiency and product consistency. Grinding equipment with automatic loading and unloading, online inspection, and data traceability can effectively reduce errors caused by manual intervention while enabling full-process monitoring of the machining process, meeting the demands of intelligent manufacturing.

Development Trends in Silicon Carbide Grinding Equipment: A Double Breakthrough in Precision and Efficiency

As silicon carbide devices evolve towards higher frequencies, higher voltages, and higher powers, higher requirements are placed on the surface quality and internal crystal integrity of the substrate material. This is driving the evolution of silicon carbide grinding equipment towards higher precision and lower damage. On the one hand, the motion accuracy of equipment continues to improve, with nanometer-level positioning accuracy and submicron-level repeatability becoming mainstream development goals. On the other hand, the integration of new grinding technologies (such as electrolytic grinding and ultrasonic-assisted grinding) with equipment can significantly reduce the depth of surface damage while increasing material removal rates, thereby reducing processing costs for subsequent processes.

Driven by the concept of green manufacturing, silicon carbide grinding equipment will also develop in an energy-efficient and environmentally friendly direction. For example, the use of high-efficiency energy-saving motors and variable frequency speed control systems can reduce equipment energy consumption. The optimized design of the grinding fluid circulation and filtration system can increase the reuse rate of grinding fluid and reduce waste discharge. The modular design of the equipment not only facilitates maintenance and upgrades but also enables efficient resource allocation, meeting the requirements of sustainable industrial development.

As a key piece of equipment in the silicon carbide industry chain, the technological advancements and innovations of silicon carbide grinding equipment are profoundly impacting the development of the third-generation semiconductor industry. From meeting basic processing needs to supporting the mass production of high-end devices, silicon carbide grinding equipment has always been looking for the best balance between precision and efficiency, stability and innovation, clearing processing obstacles for the widespread application of silicon carbide materials and promoting the rapid development of strategic emerging industries such as new energy and new generation information technology.

English

English русский

русский عربى

عربى