China-made Clinometers: The Science and Technology Behind Precision Measurement

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this crucial mission. In recent years, China-made clinometers have emerged in the global market, demonstrating strong competitiveness thanks to their superior performance and continuously innovative technologies.

I. Analysis of the Working Principle of an Inclinometer

The core mission of an inclinometer is to measure the change in an object's tilt over time, as well as the change in the plumb line over time. This functionality is achieved through ingenious scientific principles. Currently, mainstream inclinometers are based on Newton's second law, using accelerometers to sense changes in gravitational acceleration. Accelerometers contain multiple tiny masses. When an object is horizontal and stationary, gravity keeps the accelerometer pointed in the direction of Earth's gravity. Once the object tilts, the gravitational component changes, and the accelerometer keenly detects this change. Through complex and precise calculations and data processing, the inclinometer accurately displays the object's tilt value. For example, some inclinometers employ an electrolyte and conductive contacts. When the sensor tilts with an object, the electrolyte level remains horizontal, but its relative position to the contacts changes, causing a change in the output power. This change in power closely corresponds to the object's tilt and deformation, becoming a key indicator for measuring the tilt angle.

II. Wide and Diverse Applications

(I) Safety Guardians in Construction and Civil Engineering

In the fields of construction and civil engineering, inclinometers play an irreplaceable role. Whether towering skyscrapers, vast bridges spanning rivers, or tunnels deep underground, structural stability must be constantly monitored during construction and long-term operation. Inclinometers can accurately measure the tilt of buildings or structures in real time. If the tilt exceeds a safe threshold, an alarm is issued, buying valuable time for engineers to implement reinforcement and repair measures, thereby preventing potential collapses and other serious safety accidents. Inclinometers are also crucial for large-scale earth-rockfill dams and concrete dams. They constantly monitor the dam's tilt and protect the lives and property of people in downstream areas. (II) Stability Guarantee in the Transportation Sector

In the transportation sector, inclinometers also play a significant role. For heavy trucks navigating winding mountain roads, buses traversing urban roads, and various ships navigating the seas, inclinometers are crucial devices for ensuring driving stability. By measuring the vehicle or vessel's tilt angle in real time, they provide drivers with intuitive information, helping them adjust their driving maneuvers promptly and prevent dangerous situations such as rollovers caused by excessive tilt. In railway construction and maintenance, inclinometers are used to calibrate the levelness of rails, ensuring smooth and safe train operation.

(III) Precision Assistant in Industrial Automation

In today's highly developed industrial automation landscape, inclinometers have become indispensable precision measuring instruments on production lines. During machining, they precisely measure the horizontality and verticality of machined parts, ensuring machining accuracy and improving product quality. In intelligent warehousing and logistics systems, inclinometers help automated equipment accurately determine the placement angle of goods, enabling efficient and safe cargo handling and storage. During the operation of industrial robots, inclinometers provide precise posture feedback, enabling them to perform various complex tasks with greater accuracy.

III. The Rise of Chinese-Made Inclinometers

(I) Technological Innovation Breakthroughs

Chinese companies have continuously increased their investment in technological innovation in the R&D and manufacturing of inclinometers. Significant breakthroughs have been achieved in sensor technology. For example, some companies have successfully developed high-precision MEMS sensors, significantly improving the measurement accuracy and sensitivity of inclinometers. Furthermore, continuous optimization of data processing algorithms enables inclinometers to quickly and accurately analyze and process collected data, outputting precise tilt angle information. In terms of communication technology integration, advanced wireless communication technology has been applied to inclinometers, enabling real-time remote data transmission, allowing users to access monitoring data anytime, anywhere.

(II) Improved Quality and Reliability

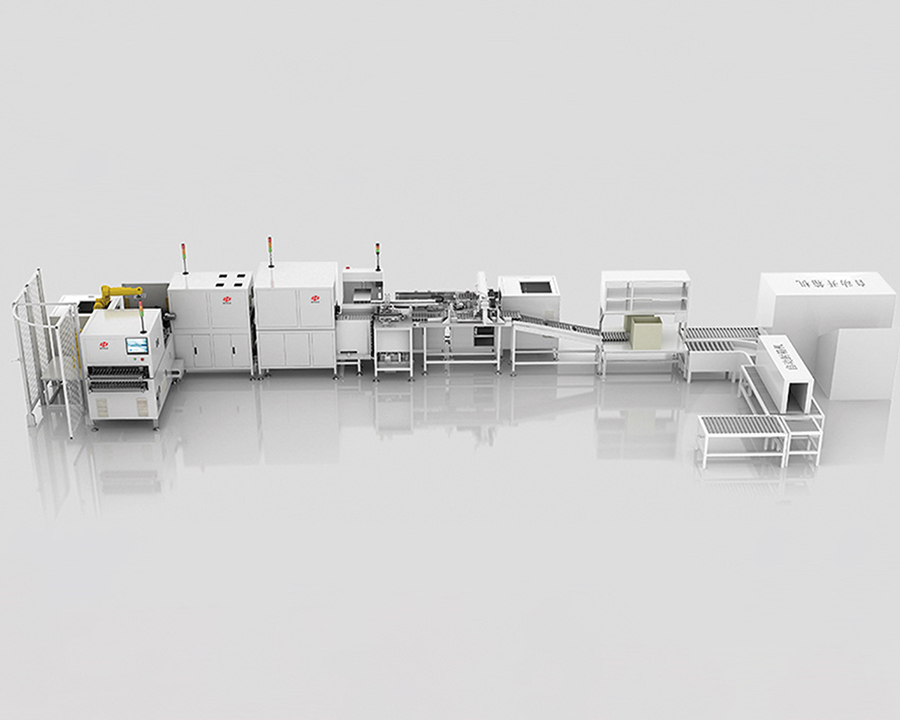

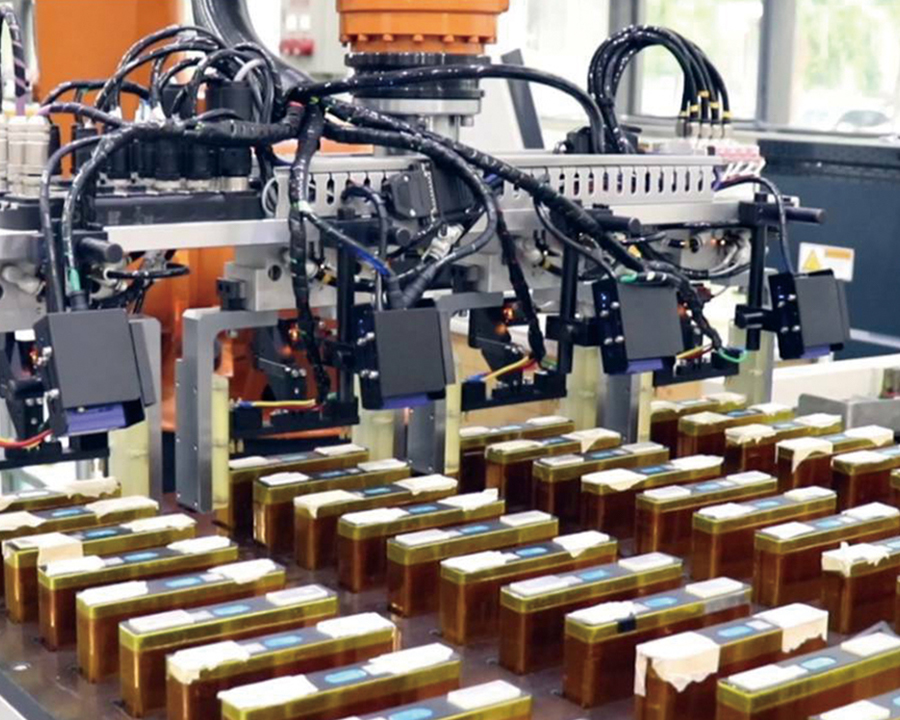

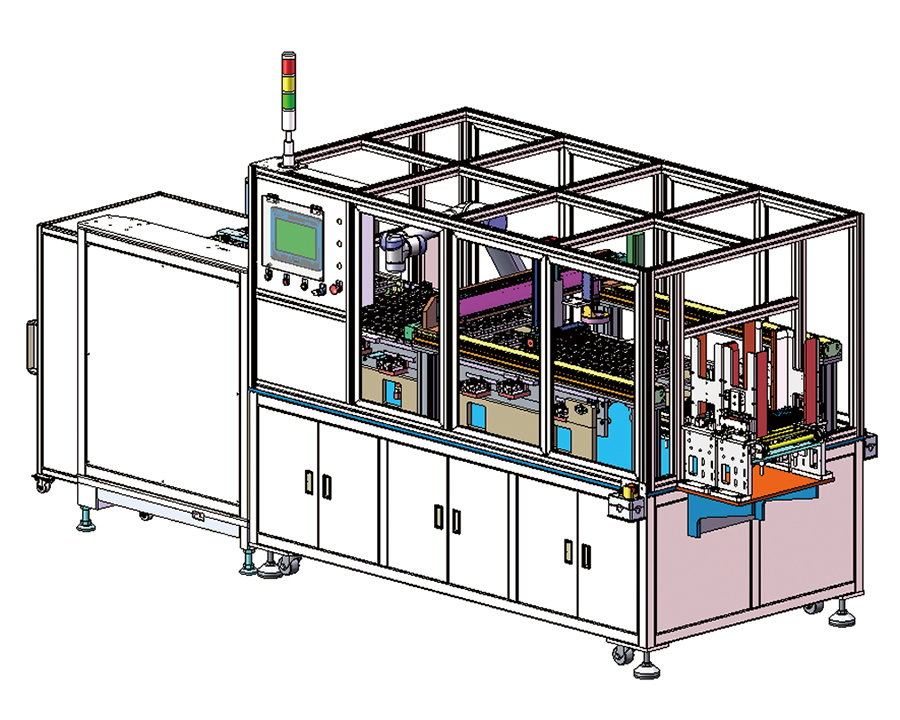

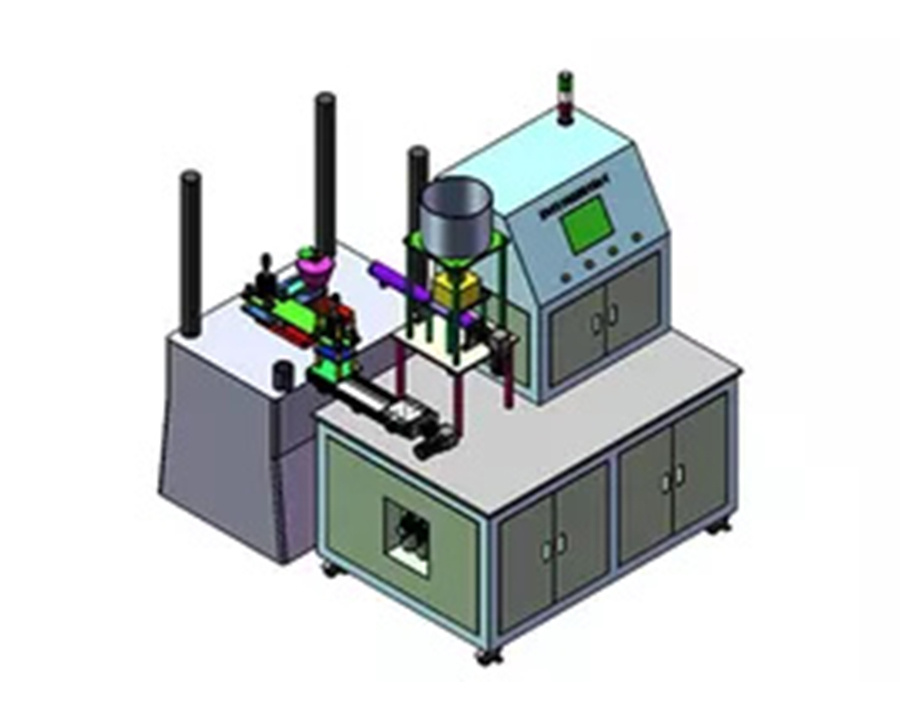

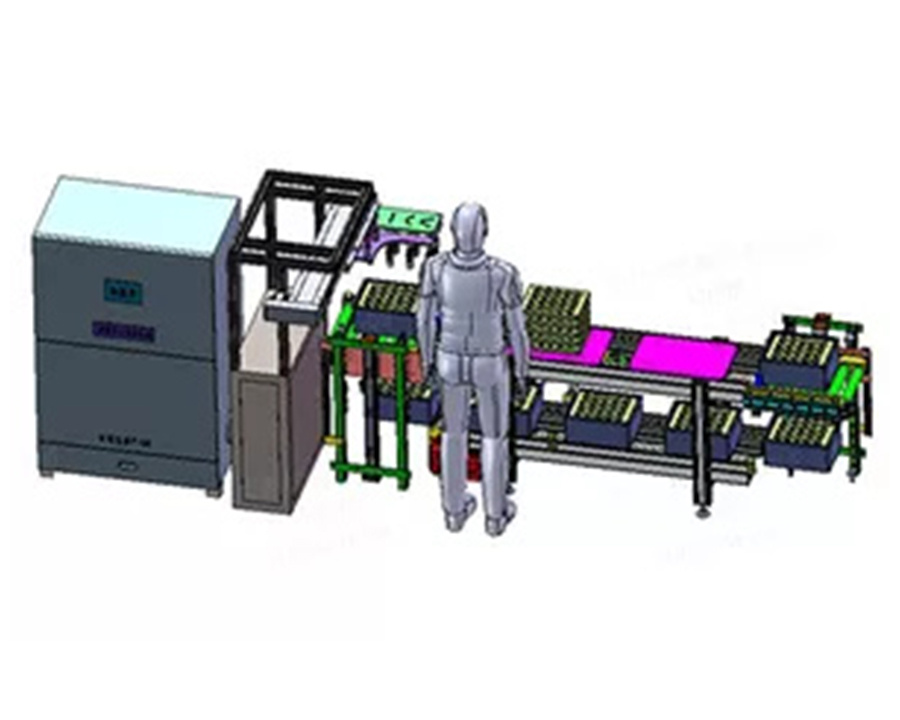

Chinese-made inclinometers demonstrate significant effort in quality and reliability. Strict control is exercised starting with raw material procurement, ensuring the use of high-quality, durable materials to ensure excellent product stability and anti-interference capabilities. During the manufacturing process, we utilize advanced automated production equipment and a rigorous quality inspection system to meticulously control every production step. Each inclinometer undergoes multiple rounds of rigorous testing before shipment, including performance testing under diverse environmental conditions and long-term stability testing, ensuring stable and reliable operation under diverse operating conditions.

China-made clinometers are illuminating the global measurement field with their unique technological capabilities and superior performance. They are poised to play a key role in even more areas in the future, continuously driving industry progress and development.

English

English русский

русский عربى

عربى