Busbar Assembly Lines: The Unsung Heroes of Power Transmission Systems

The efficient transmission and distribution of electricity is crucial in the vast networks of modern industry and infrastructure. Busbar assembly lines, as a critical link in the power system, often remain hidden behind the scenes, yet they play an irreplaceable role. They are not only the "transportation hub" that ensures the smooth flow of electricity, but also a vital force in improving production efficiency and ensuring stable system operation.

Busbar Assembly Lines: Concept and Operating Principle

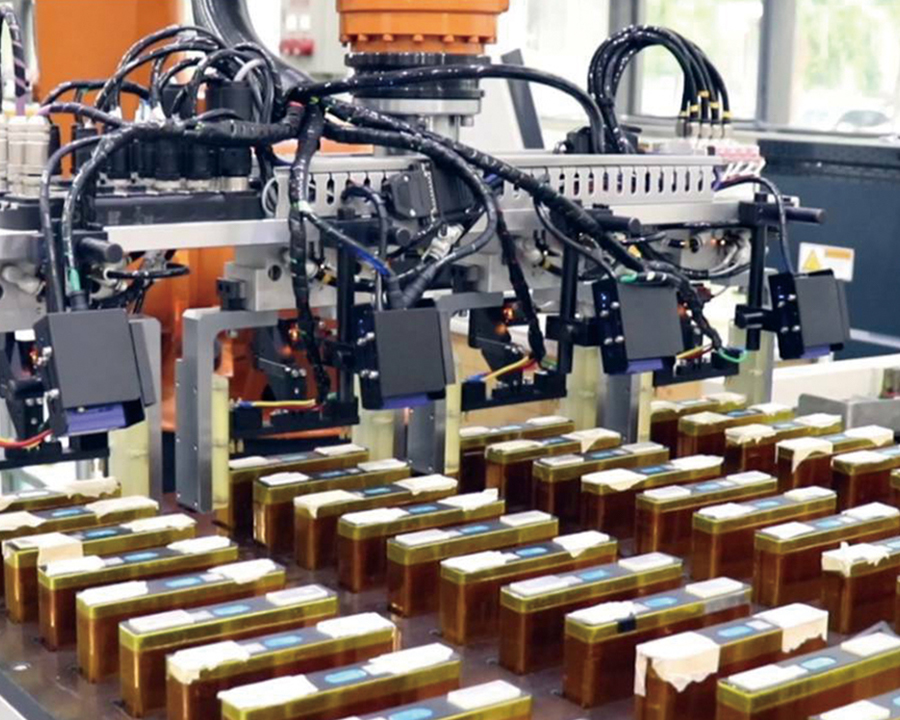

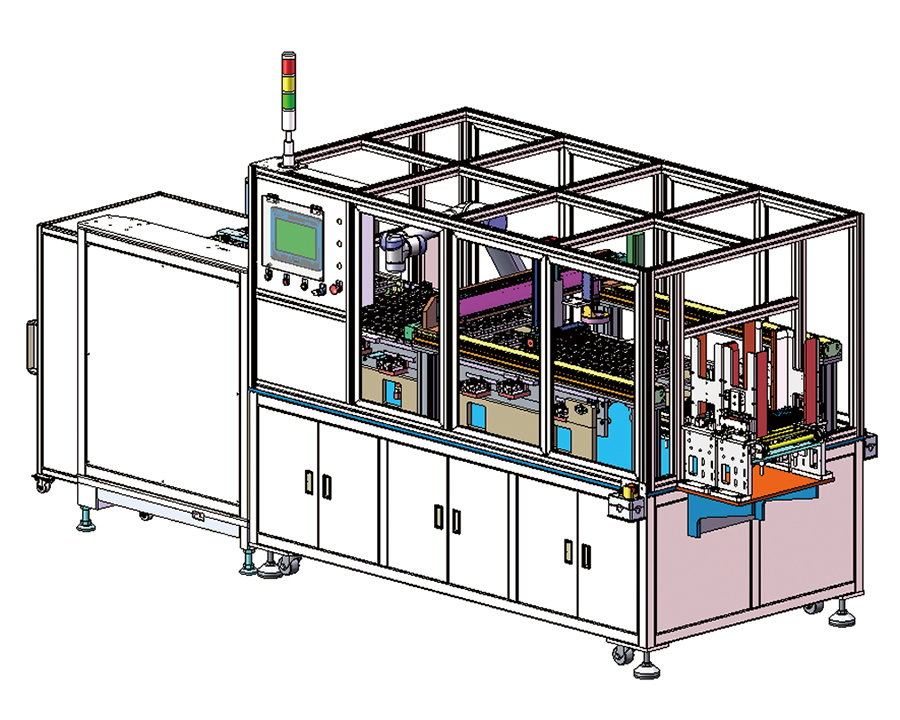

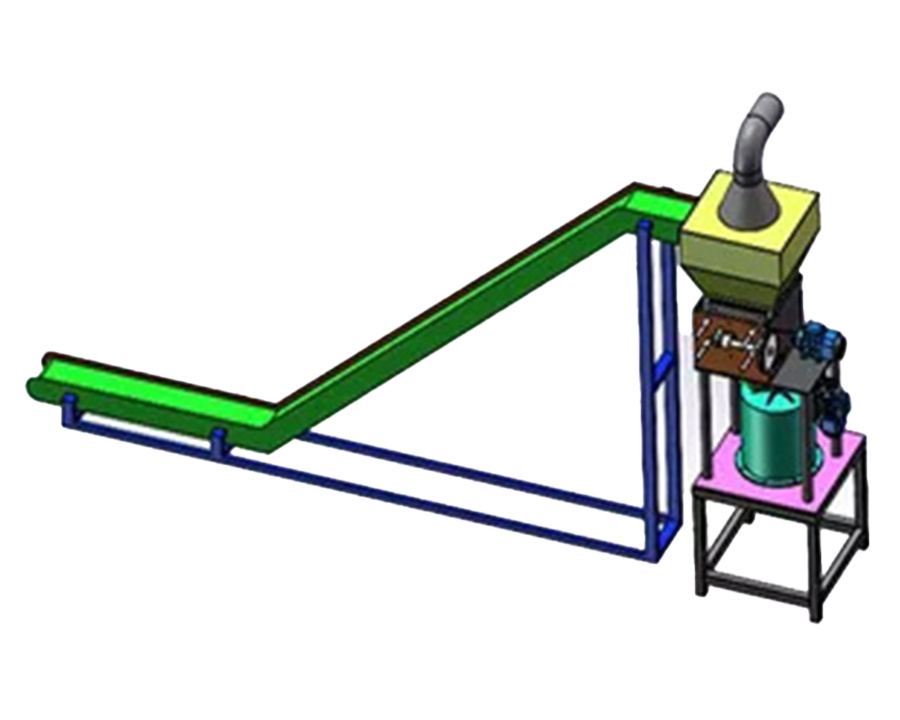

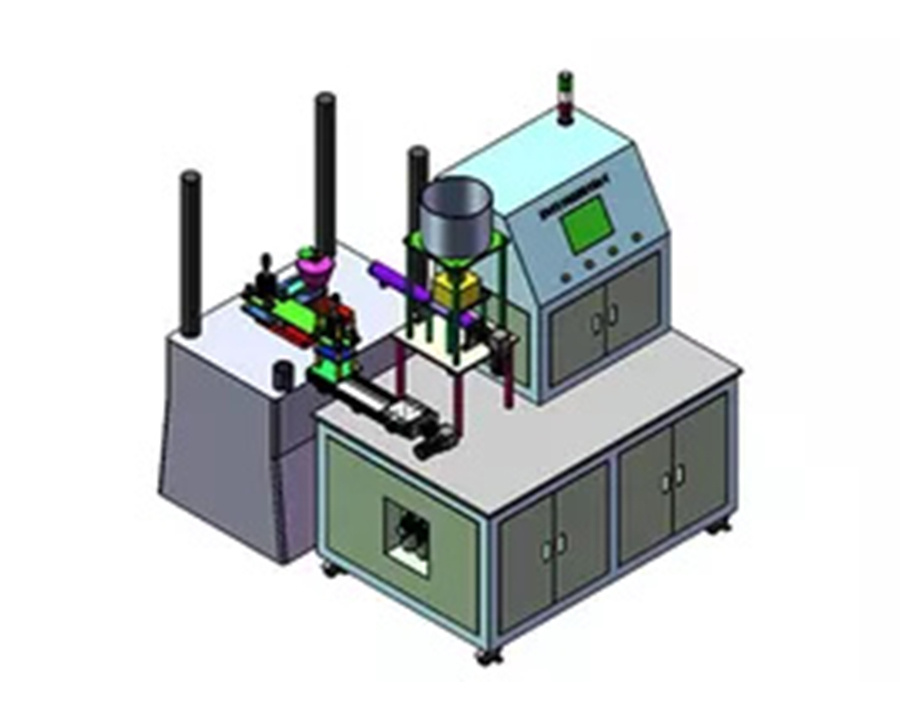

Busbars, as conductive carriers carrying high currents, are the "aorta" of the power transmission system. Busbar assembly lines are automated production systems that efficiently assemble busbars and related components. Their operating principle relies on a series of precise operational processes. First, busbars made of conductive materials such as copper or aluminum are pre-processed, such as bending and cutting, to meet various installation requirements. Subsequently, the pre-processed busbars are precisely assembled with components such as insulation and casing. Automated riveting and fastening processes ensure secure and reliable connections between components. Throughout the assembly process, advanced control systems monitor and adjust various parameters in real time to ensure consistent and stable product quality.

Automation: The Core Advantage of Busbar Assembly Lines

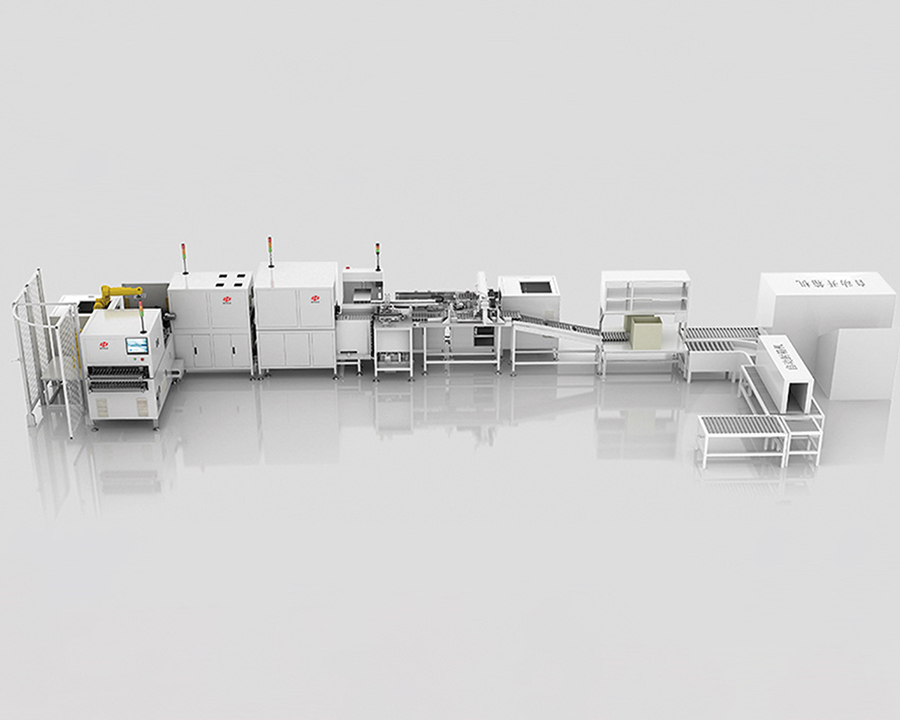

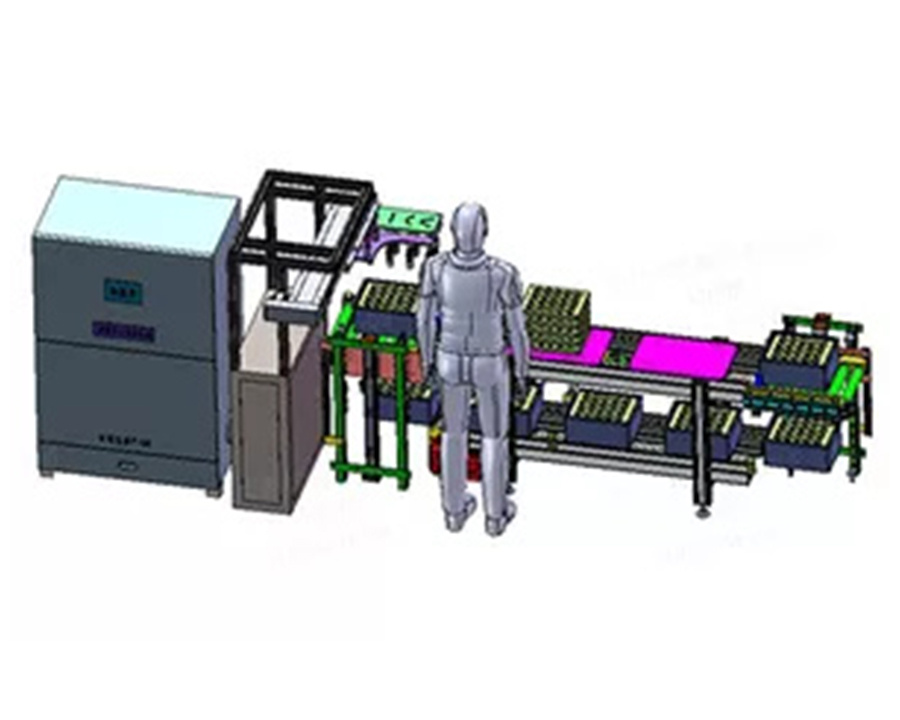

One of the hallmarks of modern busbar assembly lines is their high degree of automation. By incorporating robotics, automated conveying equipment, and intelligent control systems, busbar assembly lines enable one-stop production, from raw materials to finished product. This not only significantly reduces the errors and uncertainties associated with manual operations, but also significantly improves production efficiency. Automated assembly lines can complete tasks such as riveting and assembly at exceptionally high speeds while maintaining high product quality standards. Compared to traditional manual assembly methods, automated busbar assembly lines can produce more and higher-quality products in a shorter timeframe, meeting growing market demand.

Quality Assurance: The Outstanding Performance of Busbar Assembly Lines

In the power transmission industry, product quality is directly linked to the safe and stable operation of the system. Busbar assembly lines utilize rigorous quality control systems and advanced testing technologies to provide a solid guarantee of product quality. During the production process, high-precision sensors monitor key busbar parameters, such as dimensions and connection strength, in real time. If anomalies are detected, the system automatically adjusts or issues an alarm.

The assembly line is also equipped with advanced electrical performance testing equipment, which conducts comprehensive electrical tests on finished busbars to ensure they meet stringent industry standards and customer requirements. This comprehensive quality control approach ensures that the products produced by the busbar assembly line have higher reliability and stability, laying a solid foundation for the safe operation of power systems.

Flexibility and Customization: Meeting Diverse Needs

Different power projects have varying requirements for busbar specifications, performance, and installation methods. The busbar assembly line, with its high flexibility and customization capabilities, can easily meet these complex needs. Through flexible adjustments to the production process and modular design, the assembly line can quickly switch to produce busbar products of varying types and specifications. Whether it's heavy-duty busbar for large industrial plants or lightweight busbar for commercial buildings, the busbar assembly line can be customized to meet specific customer requirements, providing the most suitable solution for various power projects.

Industry Applications: Wide Coverage, Indispensable

Busbar assembly lines have an extremely wide range of applications, covering nearly every industry requiring power transmission and distribution. In the industrial sector, they provide stable and reliable power support for large-scale equipment and production lines in factories; in commercial buildings, they ensure the power supply for shopping malls, office buildings, and other venues; and in data centers, they carry the powerful power required for massive data processing. Busbar assembly lines also play a key role in areas such as hospitals, airports, and rail transit that require extremely high power reliability. It can be said that wherever there is a demand for electricity, there is a busbar assembly line, which has become an indispensable component of the normal operation of modern society.

English

English русский

русский عربى

عربى