Silicon Carbide Grinding Equipment: A Key Tool for Efficient and Precision Machining

Grinding plays a crucial role in numerous modern industrial production processes. This is particularly true in hard material processing, where traditional abrasives struggle to meet the dual requirements of high efficiency and precision. Silicon carbide, with its exceptional physical properties and chemical stability, has become an ideal grinding material. Consequently, the silicon carbide grinding equipment that complements it has become a focus of attention in many advanced manufacturing industries.

Silicon Carbide Material Advantages and Grinding Machine Compatibility

Silicon carbide boasts extremely high hardness, second only to diamond and cubic boron nitride. It also boasts excellent thermal conductivity, strong oxidation resistance, and the ability to operate stably and for extended periods in high-temperature environments. These properties make it suitable not only for grinding and polishing materials such as metals, ceramics, and glass, but also for becoming a key consumable in fields such as semiconductor wafer manufacturing, optical component processing, and precision mold manufacturing.

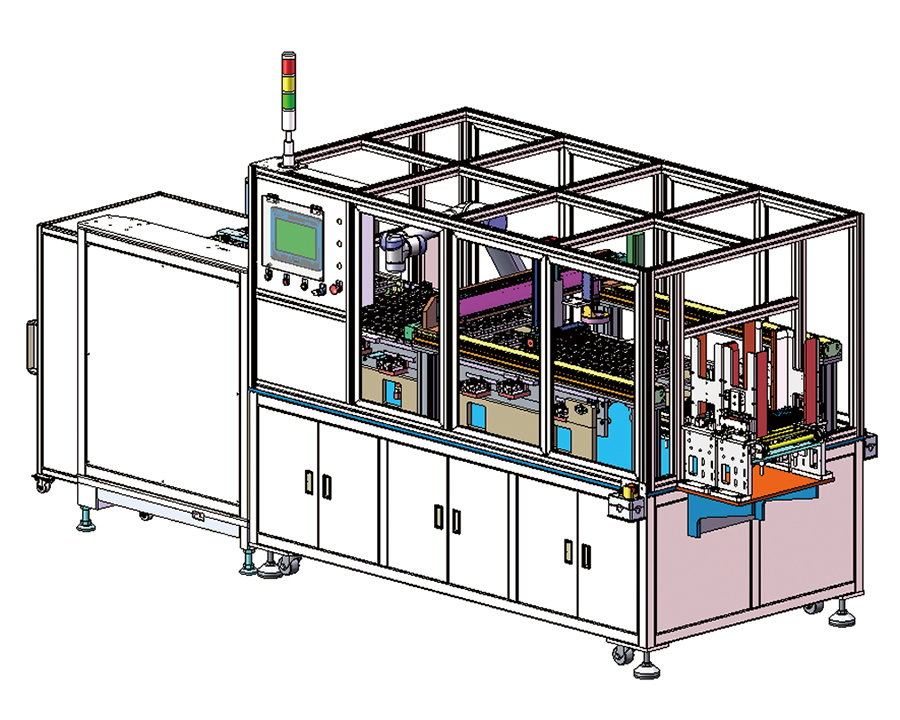

Equipment compatible with these high-performance abrasives requires precise design across multiple dimensions, including spindle speed, load control, cooling systems, and grinding wheel material. Silicon carbide can develop microcracks or crystal delamination during high-speed operation. Therefore, grinding equipment must possess sufficient dynamic rigidity and consistent grinding force output to ensure efficiency while maintaining high surface quality. High-end equipment is often equipped with intelligent control systems that enable automatic parameter adjustment and enhance process consistency.

Technical Requirements for Silicon Carbide Grinding Equipment in Precision Manufacturing

With the ongoing development of Industry 4.0, precision manufacturing is placing higher expectations on grinding equipment. This goes beyond simply matching hardness to encompass systematic processing capabilities. In particular, in the manufacturing of ultra-hard materials such as semiconductor wafers, sapphire substrates, and silicon carbide ceramics, equipment must support submicron machining accuracy, exhibit minimal thermal deformation, and maintain stable grinding force control.

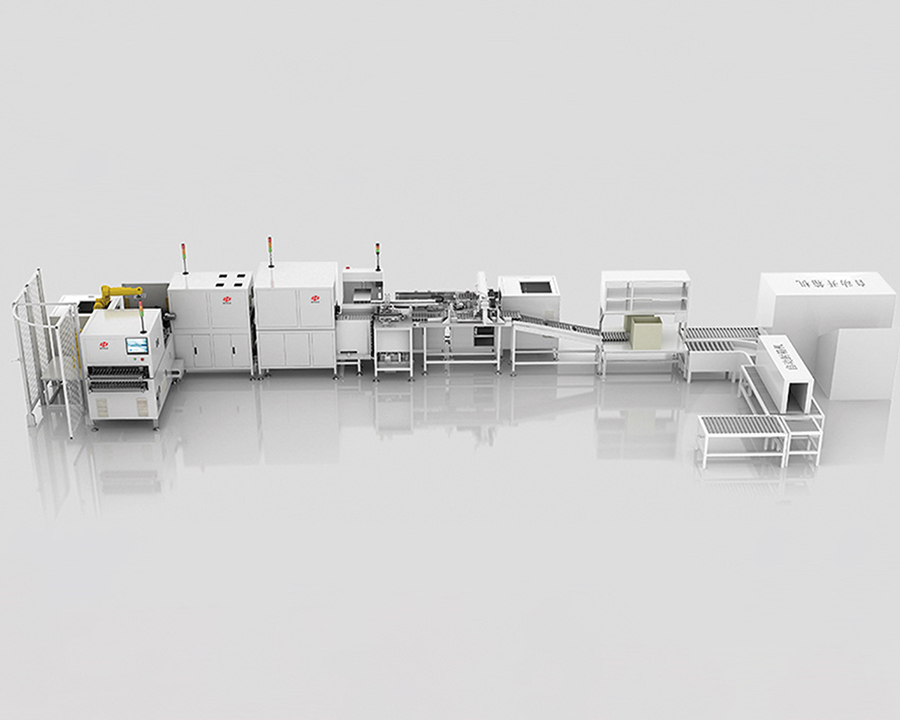

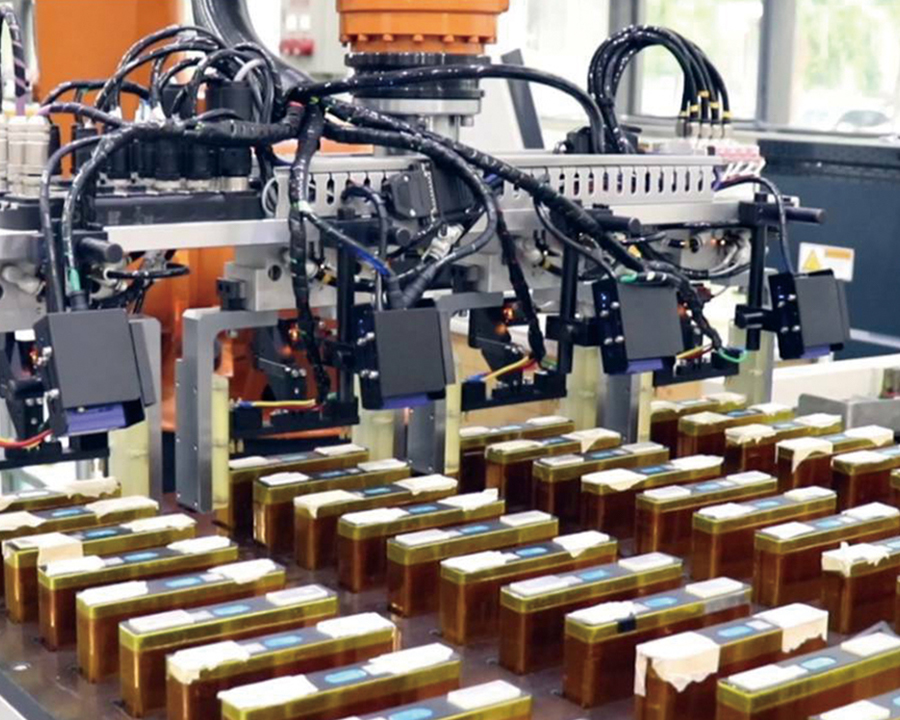

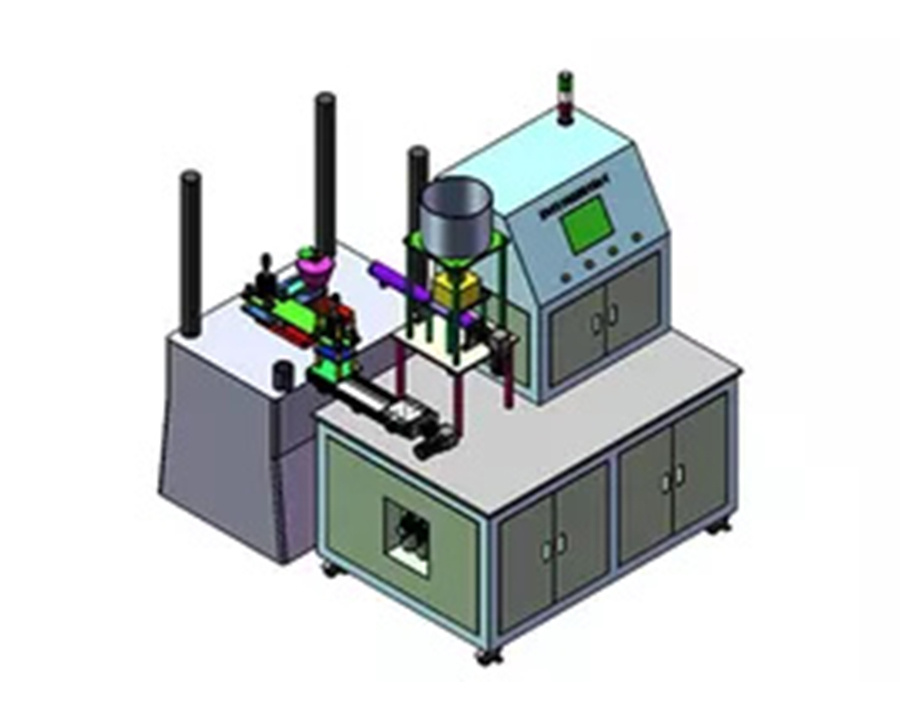

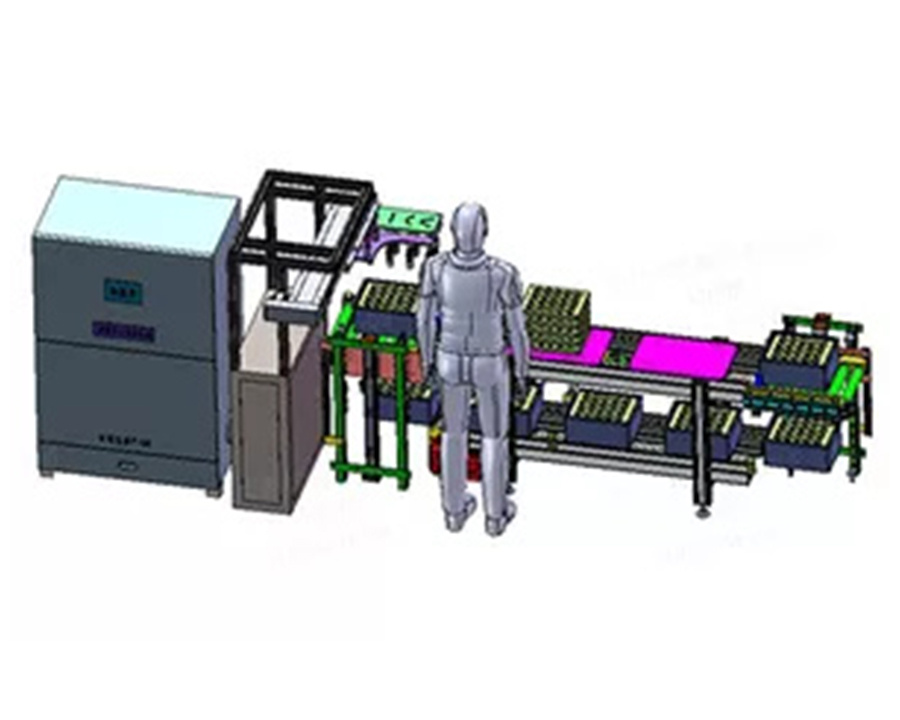

Advanced silicon carbide grinding equipment typically utilizes multi-station linkage mechanisms, enabling continuous, automated operation. It also incorporates intelligent diagnostic modules that enable self-checking of equipment status, tool life management, and processing data tracking, reducing manual intervention and significantly improving yield. Most equipment utilizes direct-drive or torque motors to minimize displacement interference caused by gear meshing errors, thereby achieving truly high-precision operation. A new generation of grinding system design concepts that balance high efficiency and environmental protection.

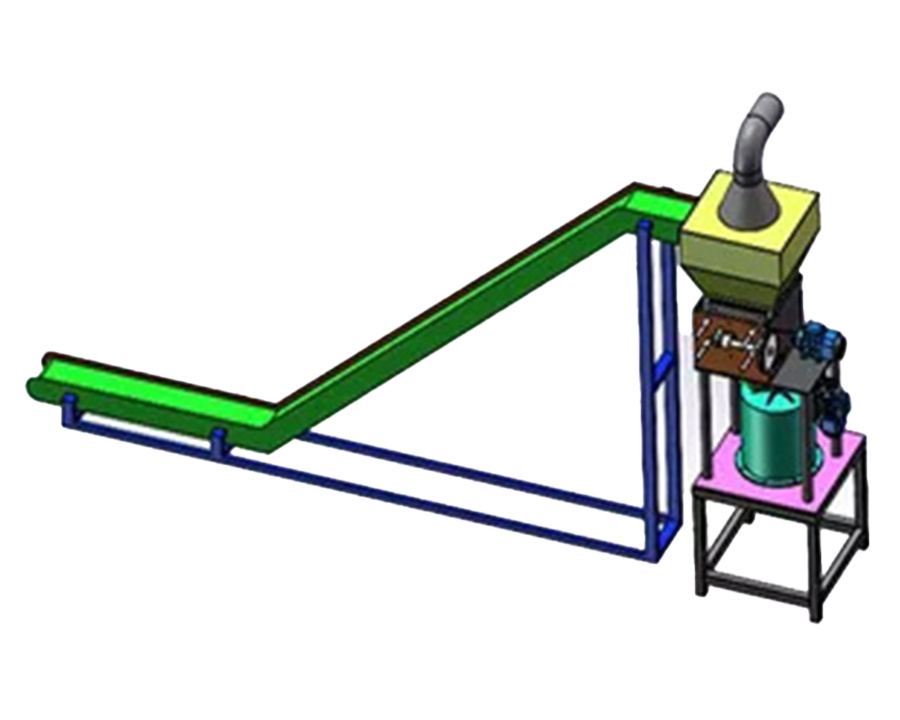

While emphasizing processing efficiency, modern silicon carbide grinding equipment also places greater emphasis on integrating energy efficiency and environmental protection. In traditional grinding operations, the extensive use of coolant is not only costly but also creates serious waste disposal challenges. New-generation systems generally utilize closed-loop cooling systems, combined with atomized lubrication and micro-cooling technology. This not only reduces overall water and oil consumption, but also significantly reduces waste discharge and processing pollution.

Automatic grinding media replacement systems, centralized waste treatment facilities, and noise suppression modules have significantly improved the working environment. Some high-end grinding equipment even incorporates negative pressure suction and electrostatic dust removal systems to ensure that harmful particles and dust are not generated when processing high-strength ceramics or crystalline materials, protecting the occupational health and safety of equipment operators.

Technological integration is reshaping the industry's competitive landscape.

With the accelerating integration of digital technologies such as artificial intelligence, the Internet of Things, and big data, silicon carbide grinding equipment is gradually evolving from traditional mechanical platforms to intelligent manufacturing units. The addition of capabilities such as interoperability between equipment, data-driven process optimization, and visual remote monitoring not only enhances process transparency but also propels enterprises' manufacturing capabilities to new heights of digitalization and intelligence.

The modular design concept for equipment is increasingly becoming mainstream in the market. Its core purpose is to meet the needs of rapid adaptability to different products with varying sizes and material properties. Modular units enable rapid replacement and commissioning, enhancing production line flexibility while saving companies significant investment costs and human resources, truly demonstrating the advantages of "flexible manufacturing."

Market Application Trends

From a market perspective, the application of silicon carbide grinding equipment is gradually expanding into new energy vehicles, high-end medical devices, aerospace, and other fields. These sectors generally face challenges with high material hardness, extremely tight machining tolerances, and high batch consistency, placing unprecedentedly stringent demands on equipment. Therefore, future equipment development will further focus on cutting-edge technologies such as ultra-high-speed spindle technology, ultrasonic-assisted grinding, and plasma-assisted polishing.

Silicon carbide grinding equipment is more than just a processing tool; it is an indispensable core process platform supporting high-end manufacturing. Against the backdrop of continuous breakthroughs in materials science and the deepening of intelligent manufacturing, this equipment system will have a wider range of applications in high-precision machining, complex surface forming, and extreme performance enhancement. Those who master the core technology of silicon carbide machining in the field of hard material grinding will likely seize the initiative in the next wave of industrial innovation.

English

English русский

русский عربى

عربى