Automatic flag-making machine: Redefining the efficiency and precision of flag production

Amidst accelerating globalization and the increasing frequency of various activities, market demand for flags, as a crucial medium for conveying information and displaying identity, continues to rise. Traditional flag-making methods rely heavily on manual labor, resulting in low production efficiency and limited precision, making them increasingly unable to meet the demands of the fast-paced modern market. The emergence of the automatic flag-making machine, like a technological revolution, has revolutionized this landscape and become a core driving force for the upgrading of the flag production industry.

The Technical Core of the Automatic Flag-Making Machine: From Mechanical Interaction to Intelligent Collaboration

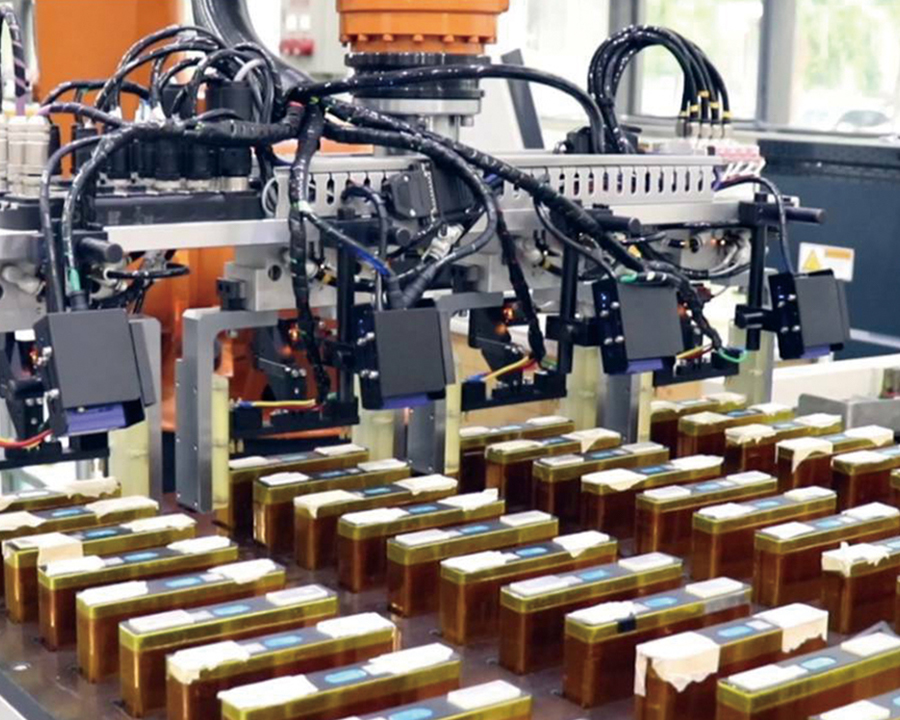

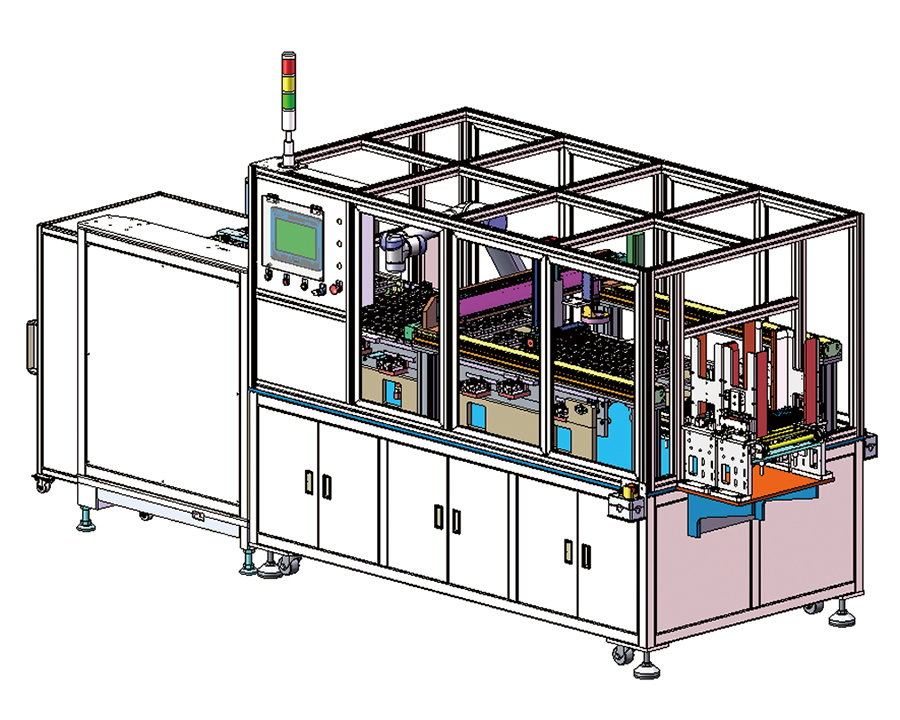

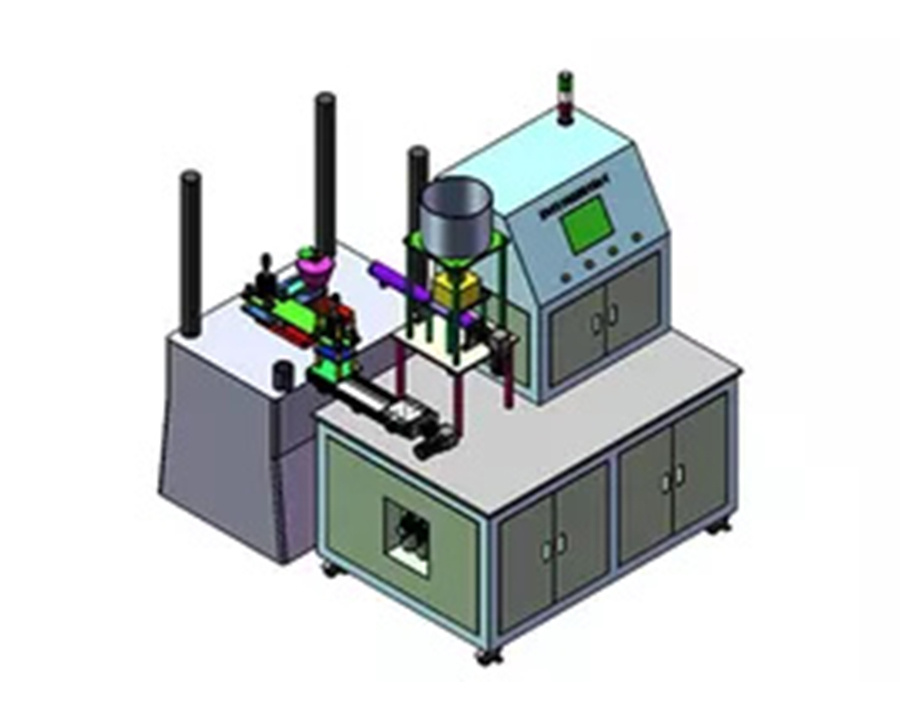

The powerful performance of the automatic flag-making machine stems from its sophisticated internal technology. This is more than a simple mechanical assembly; it represents a deep integration of mechanical structure, electronic control, and digital technology. Mechanically, high-precision guide rails and servo motors ensure smooth fabric transportation and precise cutting. Even thin, easily deformable flag fabrics can maintain stable tension during high-speed operation, preventing wrinkles and shifting. The electronic control system is the "brain" of the automatic flag-making machine. A programmable logic controller (PLC) controls each component in real time, ensuring precise execution according to preset parameters for every step, from fabric feed speed and printing position to cutting dimensions. More notably, modern automatic flag-making machines often incorporate digital twin technology, enabling virtual simulations to simulate the production process in advance, anticipate potential problems, and optimize them, significantly reducing the failure rate in actual production.

In the printing process, automatic flag-making machines break through the limitations of traditional processes, employing high-precision inkjet or thermal transfer technology to achieve precise color reproduction and detailed pattern rendering. Whether it's complex gradients or fine line textures, these can be perfectly reproduced through the digital color management system, with color fastness and durability far exceeding traditional hand-printing. This ensures that the flags retain their vibrant colors even after extended outdoor use. Reshaping the Flag Production Model: From Distributed Processing to Integrated Processing

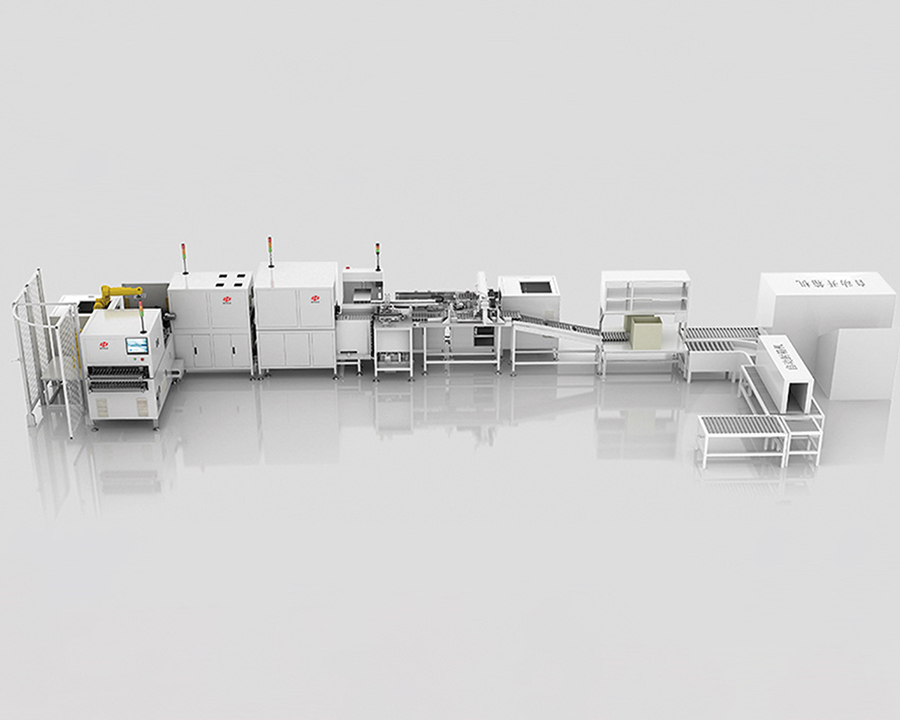

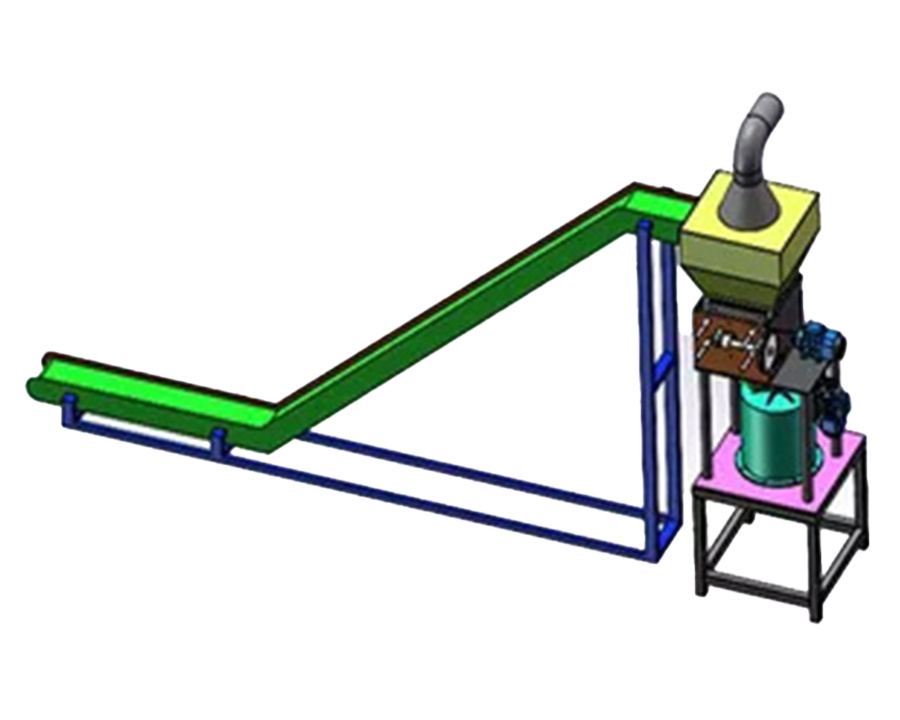

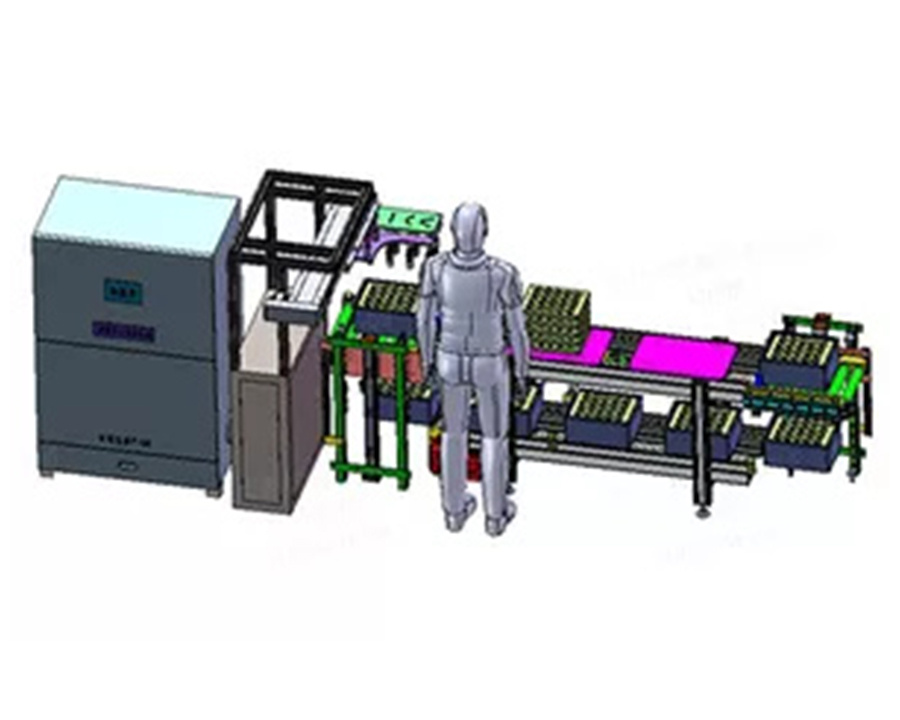

Traditional flag production often involves multiple discrete steps, such as fabric cutting, pattern printing, and edge processing. The connections between these steps rely on manual handling and adjustments, which not only prolongs the production cycle but also increases the potential for errors. The automatic flag-making machine, through its integrated design, integrates these discrete processes into a continuous production line, automating the entire process from fabric input to finished product output.

After the fabric enters the machine, it first passes through an automated inspection system, which quickly identifies flatness and defects. If any issues are detected, an alarm is immediately issued and production is halted, preventing unqualified fabric from entering subsequent processes. Subsequently, based on pre-set pattern and size parameters, the machine automatically completes printing, cutting, and even overlocking the edges of the flag in a single step. This integrated model not only reduces the production cycle by more than half, but also minimizes manual intervention, reducing errors at the source.

Automatic flag-making machines also offer strong production flexibility. Traditional equipment requires time-consuming mechanical adjustments and parameter settings when changing product specifications. However, automated flag-making machines utilize digital control systems, allowing for quick adjustments by simply entering new parameters into the user interface. This allows for rapid switching between flags of varying specifications and designs. This flexible production capability enables companies to more flexibly respond to fluctuating market orders, efficiently completing both small-batch customization and large-scale standardized production.

Promoting Industry Upgrade: From Labor-Intensive to Technology-Driven

The flag-making industry has long been labor-intensive, with business development heavily dependent on the number and skill levels of its workforce. This has resulted in high labor costs and inconsistent product quality due to operational differences. The widespread adoption of automated flag-making machines is driving the industry's shift from a labor-intensive to a technology-driven model.

On the one hand, automated production significantly reduces the need for labor, freeing up more manpower from repetitive tasks and allowing companies to focus on higher-value activities such as product design and market development. On the other hand, technological advancements have also placed new demands on practitioners. Operators must master the operation and maintenance of digital control systems, driving the overall industry's talent structure towards a more highly skilled and qualified workforce.

Automatic flag-making machines also demonstrate significant environmental advantages. Traditional printing processes often produce large amounts of wastewater and exhaust gases, polluting the environment. Modern automatic flag-making machines, however, utilize digital printing technology, utilize environmentally friendly inks, and achieve high ink utilization rates, significantly reducing pollutant emissions. Furthermore, the equipment's energy consumption is precisely regulated through intelligent control systems, achieving energy conservation and emission reduction goals, in line with current green production development concepts.

The emergence of automatic flag-making machines represents not only a step forward in flag production equipment but also a revolution in the production methods and development concepts of the entire industry. Leveraging technology, they have driven comprehensive improvements in production efficiency, product quality, and environmental performance, injecting new vitality into the flag-making industry. In the future, with continued technological breakthroughs, automatic flag-making machines will undoubtedly demonstrate their value in even more areas, propelling the flag-making industry toward a new stage of smarter, more efficient, and more sustainable development.

English

English русский

русский عربى

عربى