Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has become an essential material for new energy vehicles, 5G communications, photovoltaic power generation...

READ MORE

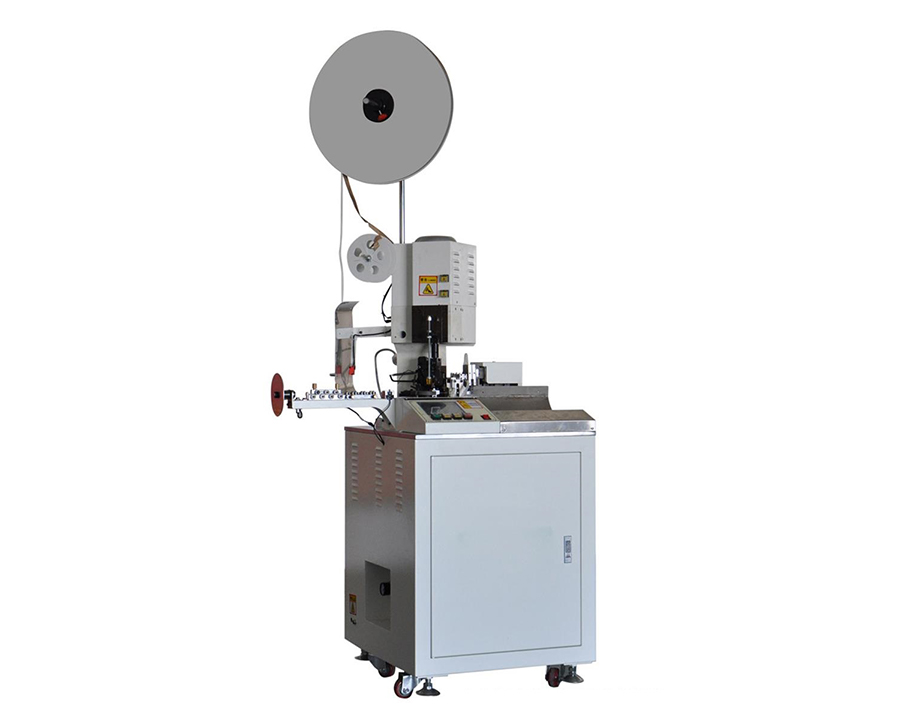

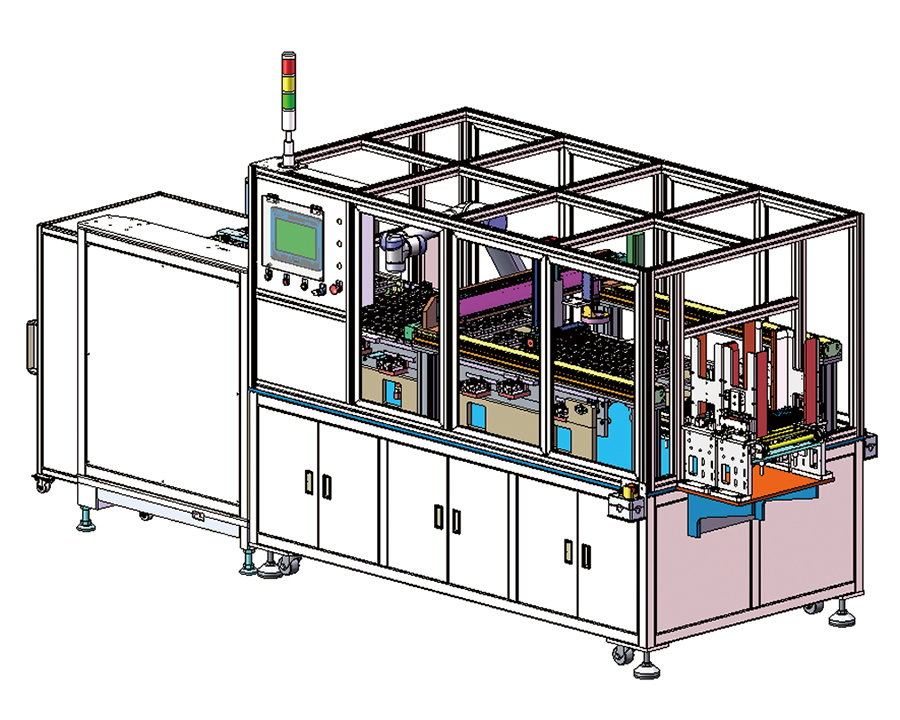

Wire harness machine

The wire harness machine integrates automation and intelligence, and is specially designed for cable cutting, stripping, crimping and other processes. Taking the processing of 500mm 5-core cables as an example, the production capacity can be as high as 950pcs/h, easily meeting the needs of mass production. need. In terms of driving mode, we use servo stepper motors, combined with the cylinder screw guide transmission system, to make the machine more stable and smooth during operation and greatly improve work efficiency. Using a programmable CNC system, the machine can flexibly respond to cable processing tasks with different needs, achieving truly automated and intelligent production. Whether it is in the automotive, electronics, communications or home appliance industries, as long as there is a need for cable processing, this high-efficiency wire harness machine can bring an efficient, accurate and intelligent cable processing experience.

Who are we?

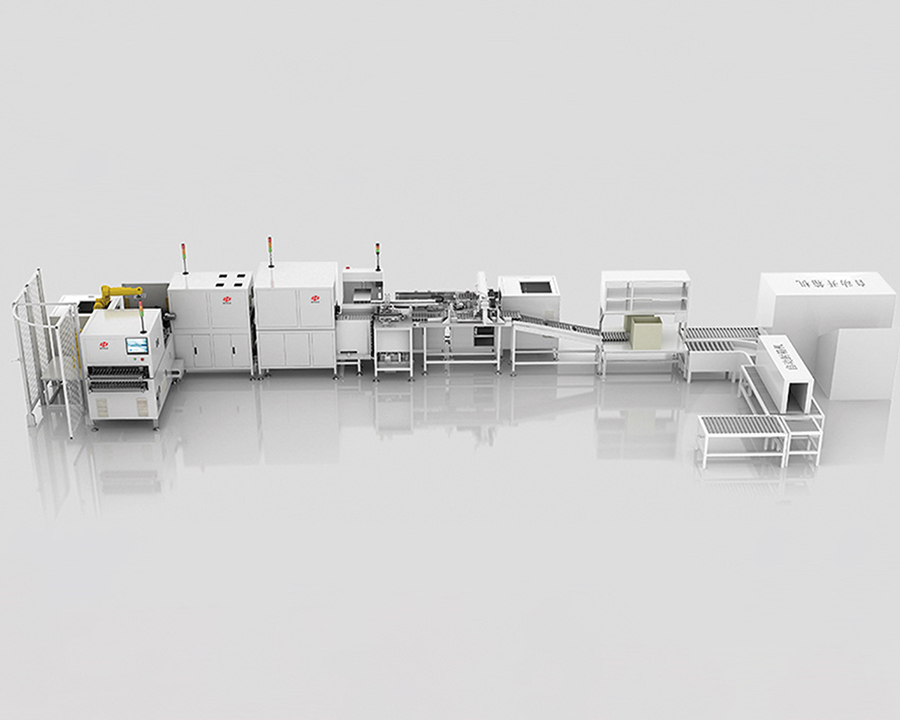

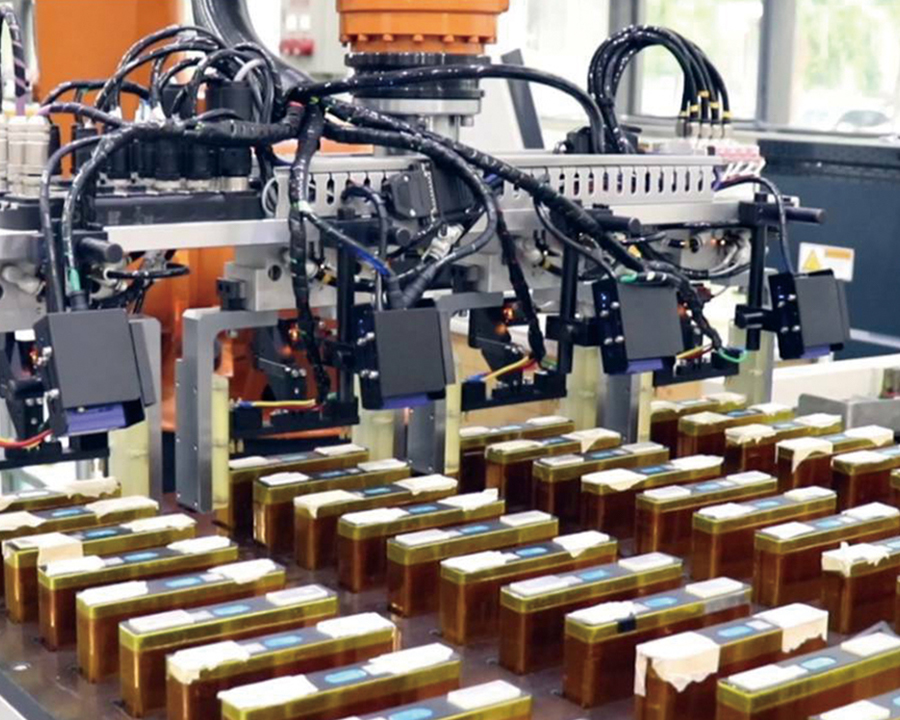

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are china Automatic Wire Harness Machine Suppliers and Intelligent Wire Harness Machine Manufacturers, Factory. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

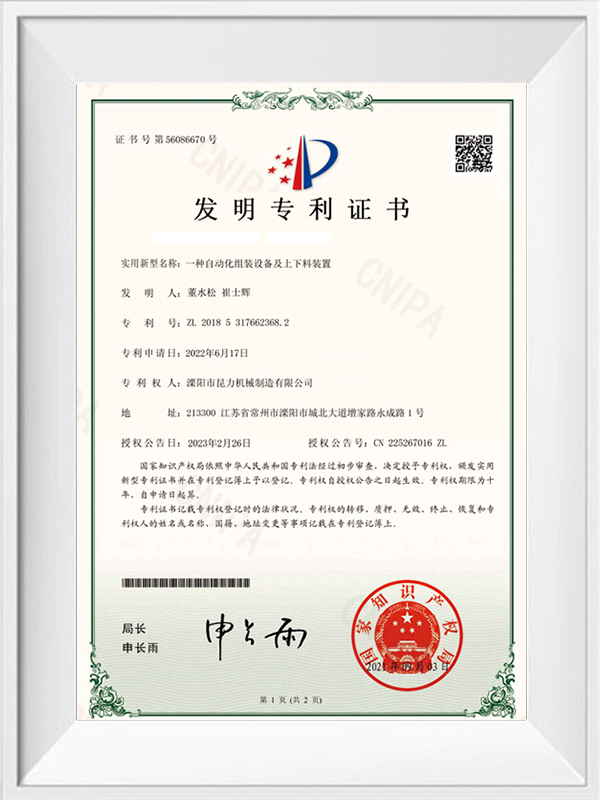

Qualifications we have obtained

Authentic reliable quality naturally stands out and fears no comparison. Professional Wire harness machine Suppliers.

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this crucial mission. In recent years, China-made clinometers have emerged in the global market, demonst...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern industry and infrastructure. Busbar assembly lines, as a critical link in the power system, often r...

READ MORE

English

English русский

русский عربى

عربى