Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

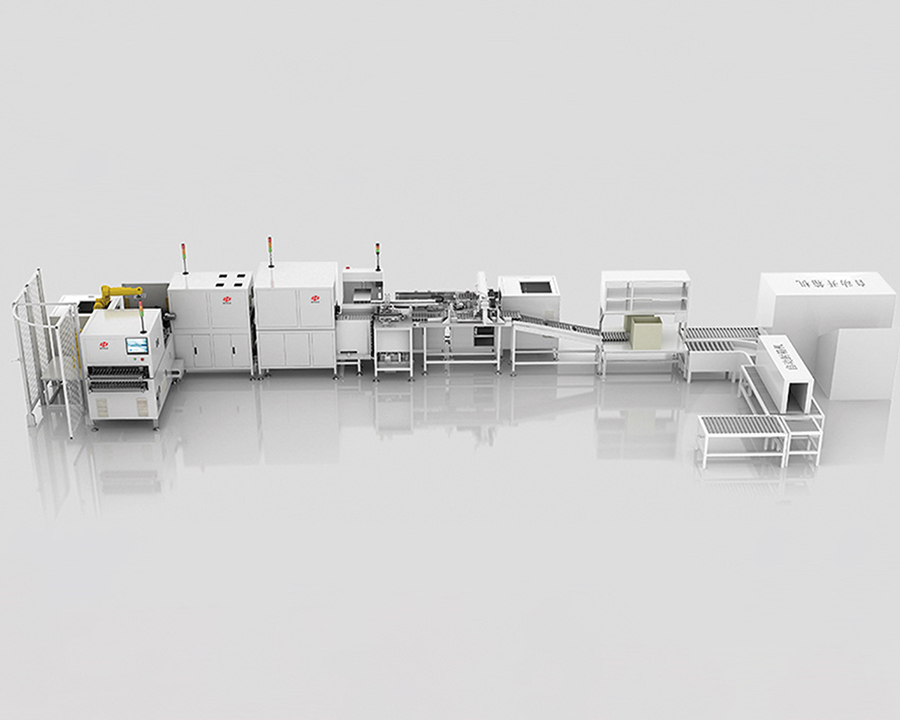

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

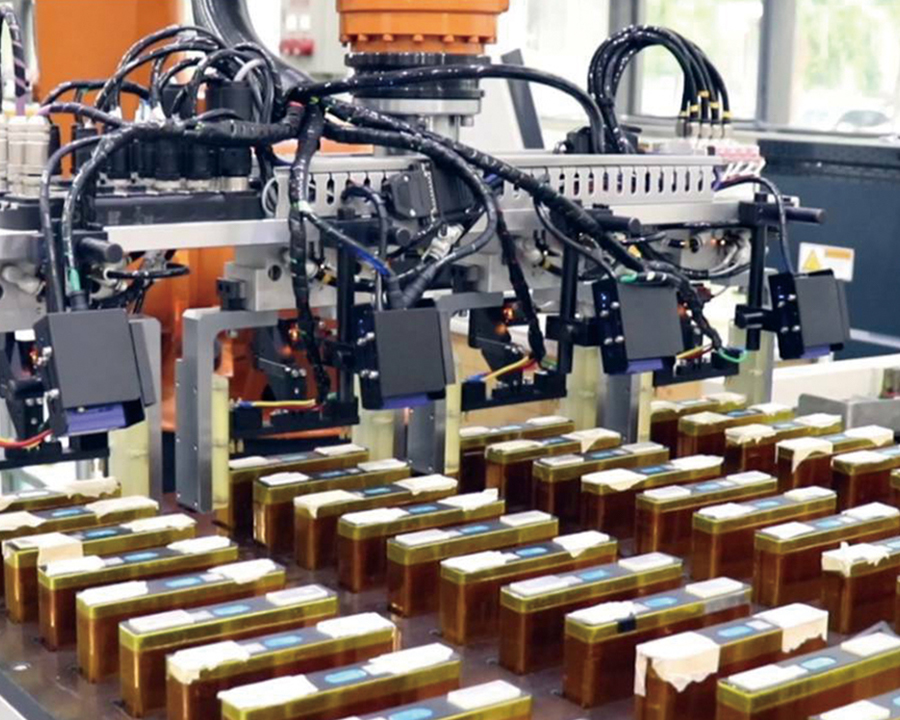

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Smart Digital Factory

Who are we?

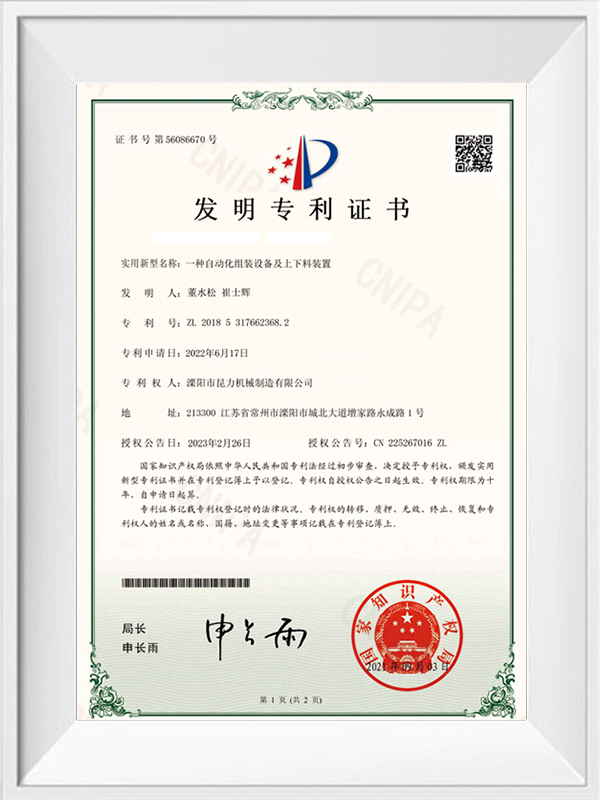

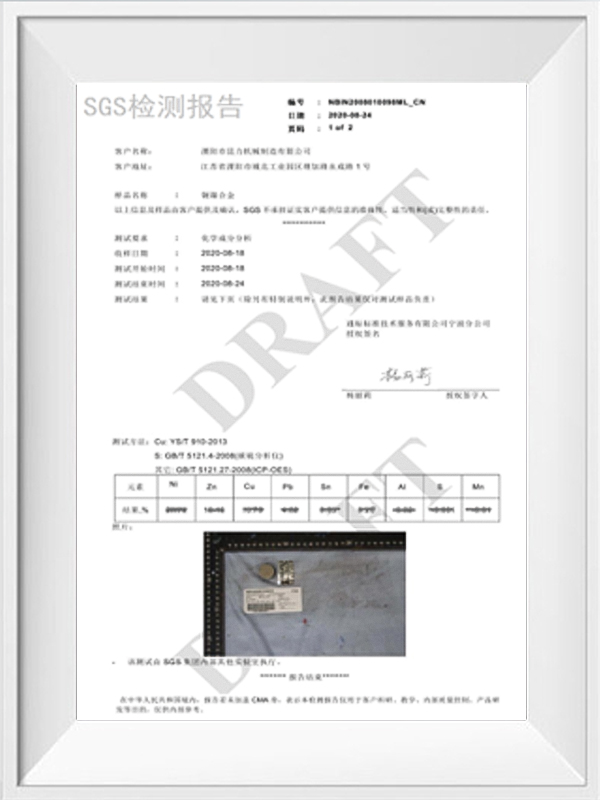

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Smart Digital Factory Suppliers and Smart Digital Factory Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

Smart digital factory: Without these key technologies, how can we lead the transformation and upgrading of the manufacturing industry?

In the wave of digital transformation of the manufacturing industry, the intelligent digital factory is becoming the core driving force for industrial transformation with its efficient, flexible and sustainable characteristics. Behind its successful operation, it is inseparable from a series of advanced and complementary key technical support.

Internet of Things technology is the foundation of the intelligent digital factory. By installing information sensing equipment on objects such as equipment, sensors, and controllers, objects and objects can be interconnected and interoperable with each other, and objects and networks can be realized. These devices can collect data in the production process in real time, such as temperature, humidity, pressure, position, etc., and transmit the data to the central control system. The central control system processes and analyzes the data to provide data support for production decisions.

With the application of Internet of Things technology, intelligent digital factories generate massive amounts of data every day. Big data technology is responsible for processing and analyzing this data. Through data cleaning, integration, classification, mining and other technical means, valuable information such as equipment operation status, product quality, production efficiency, etc. can be extracted. This information can not only help enterprises optimize production processes and improve production efficiency, but also provide strong support for enterprise decision-making.

Cloud computing technology provides powerful computing power and data storage capabilities for intelligent digital factories. Through the cloud computing platform, enterprises can realize centralized management and analysis of production data and improve the efficiency and accuracy of data processing. At the same time, cloud computing technology can also provide enterprises with flexible computing resources, flexibly allocate them according to production needs, and reduce the operating costs of enterprises.

Artificial intelligence technology plays an increasingly important role in intelligent digital factories. Through machine learning, deep learning and other technical means, artificial intelligence can conduct in-depth analysis of production data and discover the laws and trends hidden in the data. These laws and trends can help enterprises predict the operating status of equipment, product quality problems, etc., take corresponding measures in advance, and avoid potential risks. Artificial intelligence can also realize automatic control of the production process, reduce manual intervention, and improve production efficiency.

Digital twin technology is an emerging technology in intelligent digital factories. It realizes real-time monitoring and prediction of physical factories by establishing a virtual model corresponding to the physical factory. Digital twin technology can help enterprises discover problems in the production process in time, predict equipment failures, perform maintenance and repairs in advance, and avoid production interruptions. At the same time, digital twin technology can also provide strong support for enterprises' product research and development, process optimization, etc.

The successful operation of intelligent digital factories is inseparable from the support of key technologies such as the Internet of Things, big data, cloud computing, artificial intelligence and digital twins. The continuous development and application of these technologies will drive intelligent digital factories to a higher level and inject new impetus into the transformation and upgrading of the manufacturing industry.

English

English русский

русский عربى

عربى