Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Medium Frequency Resistance Welding Equipment

Resistance welding machine refers to a type of welding equipment that uses the principle of resistance heating to weld. Resistance welding machines can be divided into different types according to different uses and requirements. From the welding method classification, there are spot welding machines, seam welding machines, projection welding machines and butt welding machines, etc.; from the electrode pressurization form classification, there are lever type, electric cam type, pneumatic type, hydraulic type and pneumatic and hydraulic combined type, etc. According to the welding current types of resistance welding machines, there are single-phase power frequency welding machines, secondary rectifier welding machines, three-phase low-frequency welding machines, capacitor energy storage welding machines and inverter power supply welding machines. The resistance welding machine is mainly composed of the main circuit part, the pressure transmission part and the control part.

Who are we?

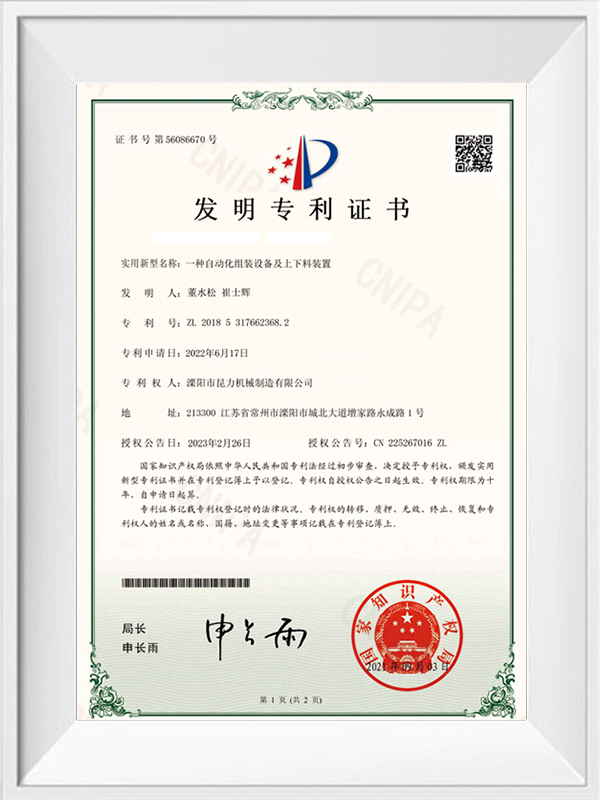

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Medium Frequency Resistance Welding Equipment Suppliers and Automatic Resistance Welding Equipment Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

How does the medium frequency resistance welding equipment monitor the power supply output status in real time and make adjustments to ensure the current is stable?

The medium frequency resistance welding equipment uses a series of advanced technical means to monitor the power supply output status in real time and make adjustments to ensure the stability of the current during welding. The specific implementation methods are as follows:

Real-time monitoring technology:

The medium frequency resistance welding equipment is equipped with high-precision current and voltage sensors, which can capture the current and voltage data of the power supply output in real time.

The data collected by the sensor will be quickly transmitted to the control system of the equipment, and the control system will analyze the data in real time.

Control system analysis:

The control system has built-in advanced algorithms and logical judgments, which can judge whether the power supply output status is stable based on the received current and voltage data.

If the output status is found to be unstable, the control system will immediately start the adjustment mechanism.

Adjustment mechanism:

The control system will change the output status of the power supply by adjusting the output frequency, duty cycle and other parameters of the inverter according to the preset current stability parameters.

During the adjustment process, the control system will continuously monitor the changes in current and voltage until the current stabilizes within the preset range.

Feedback loop:

After the adjustment is completed, the control system will detect the power supply output status again to ensure the current is stable.

If the current is still unstable, the control system will start the adjustment mechanism again to form a closed feedback loop until the current stabilizes.

Safety and reliability:

During the entire process, the control system will also monitor the temperature, load and other parameters of the equipment to ensure that the equipment operates within a safe range.

If the equipment is overloaded, overheated or in other abnormal conditions, the control system will immediately cut off the power supply to protect the equipment from damage.

Through the above technical means, the medium-frequency resistance welding equipment can monitor the power output status in real time and make adjustments to ensure the stability and reliability of the current during welding.

What are the unique advantages of medium frequency resistance welding equipment in terms of current stability and adjustability when compared with other welding technologies (such as high frequency and industrial frequency)?

Medium frequency resistance welding equipment shows obvious advantages in current stability and adjustability when compared with other welding technologies such as high frequency and industrial frequency. The following is a detailed analysis of these advantages:

Current stability:

Medium frequency resistance welding equipment uses medium frequency current, and its frequency range is usually between 1kHz and 10kHz, which helps to reduce current fluctuations and ensure current stability during welding. In contrast, although high frequency current has a faster heating speed, it may be accompanied by larger current fluctuations; while industrial frequency current is difficult to achieve the same stability due to its lower frequency.

Medium frequency resistance welding equipment uses an advanced control system that can monitor the power supply output status in real time and adjust it to ensure the stability of the current. This closed-loop control mechanism makes medium frequency resistance welding equipment more advantageous in current stability.

Current adjustability:

Medium frequency resistance welding equipment usually has precise parameter adjustment functions, and users can adjust parameters such as current size, welding time and pressure according to welding requirements. This adjustability enables medium frequency resistance welding equipment to adapt to the welding needs of workpieces of different materials and thicknesses.

Compared with high-frequency and industrial frequency welding technologies, medium-frequency resistance welding equipment is more outstanding in current adjustability. Although high-frequency welding technology can achieve high-speed welding, the current adjustment range may be narrow; and industrial frequency welding technology is difficult to achieve precise current adjustment due to technical limitations.

Medium-frequency resistance welding equipment performs well in current stability and adjustability. These advantages make medium-frequency resistance welding equipment have a wide range of application prospects in the field of welding. Whether it is for welding large parts or spot welding of small parts or thin plates, medium-frequency resistance welding equipment can provide stable and reliable welding results.

English

English русский

русский عربى

عربى