Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Who are we?

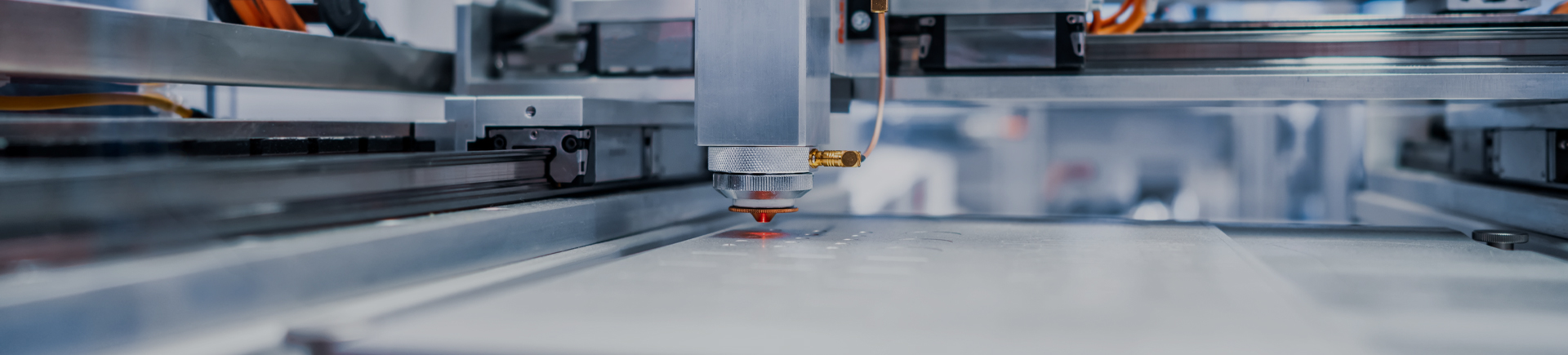

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Physical Descaling Device Suppliers and Physical Descaling Device Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

When designing a physical descaling device, how can the manufacturer ensure that the device will not cause any form of damage or scratches to the surface of the equipment being descaled?

Select the appropriate descaling technology:

The manufacturer will select the appropriate physical descaling technology, such as ultrasonic cleaning, mechanical cleaning or water pressure cleaning, according to the material of the equipment being descaled, the nature of the scale layer and the operating environment of the equipment.

Accurately control the descaling parameters:

For mechanical cleaning, the manufacturer will select appropriate scraping and brushing tools, such as wire brushes, scrapers, etc., and control their strength and speed to avoid excessive wear on the surface of the equipment.

For water pressure cleaning, the manufacturer will adjust the water flow pressure and flow rate to ensure that while effectively removing the scale layer, it will not cause damage to the surface of the equipment.

Design an intelligent control system:

The manufacturer will integrate an intelligent control system in the equipment to automatically adjust the descaling parameters according to the real-time monitoring of the descaling effect and the surface status of the equipment to ensure the safety and effectiveness of the descaling process.

Use protective materials:

During the descaling process, the manufacturer may cover the surface of the descaling equipment with a layer of protective materials, such as rubber pads, plastic films, etc., to reduce the direct contact of the descaling tool with the surface of the equipment, thereby reducing the risk of damage.

Conduct rigorous testing and verification:

After the equipment design is completed, the manufacturer will conduct rigorous testing and verification, including simulating the actual descaling environment and operating conditions to evaluate the potential impact of the equipment on the surface of the descaling equipment.

How can physical descaling device suppliers control and reduce the noise or vibration impact generated by the physical descaling device during the descaling process?

Select descaling devices with low noise and low vibration design:

When designing and producing physical descaling devices, priority should be given to the use of low noise and low vibration materials, components and processes.

Reduce noise and vibration caused by metal vibration, high-speed relative motion, etc. by optimizing the mechanical structure.

Use sound insulation and vibration reduction materials:

Use sound insulation materials such as sound insulation silk cotton in key parts of the physical descaling device to absorb and reduce the spread of noise.

Install vibration reduction pads or vibration absorbers at the bottom of the device or near the vibration source to reduce the impact of vibration on the surrounding environment and equipment.

Install sound insulation facilities:

Place the physical descaling device in a special noise isolation room or soundproof box to reduce the impact of noise on the external environment.

For equipment that cannot be completely enclosed, consider installing sound insulation panels or sound barriers around it to block the spread of noise.

Reasonable adjustment of operating parameters: According to the actual descaling needs and equipment performance, the operating parameters of the physical descaling device, such as power, frequency, etc., should be reasonably adjusted to reduce unnecessary noise and vibration. Through experiments and debugging, find the best combination of parameters to strike a balance between descaling effect and noise/vibration control. Improve the airtightness of the equipment: Improving the airtightness of the physical descaling device can reduce the noise and vibration caused by air flow and liquid flow. For example, use pipes and joints with good sealing to reduce leakage and noise. Regular maintenance and care: Regularly maintain and care for the physical descaling device to ensure that it is in good working condition. Replace worn parts in time and adjust loose connections to reduce noise and vibration caused by equipment failure or aging.

English

English русский

русский عربى

عربى