Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom New Energy Lithium Battery Automation Equipment

New energy lithium battery equipment is mainly used in the manufacturing process of lithium batteries, including preparation of positive and negative electrode materials, electrolyte injection, battery assembly and other links. They use advanced automation and intelligent technologies to ensure efficient, precise and reliable battery production. Charging and battery swapping equipment provides convenient charging services for electric vehicles and also meets the battery swapping needs in some specific scenarios. They adopt fast charging technology, which greatly improves charging efficiency and provides strong support for the popularization of electric vehicles. The battery management system device is responsible for monitoring the status of the battery, including power, temperature, voltage and other parameters, to ensure the safe operation of the battery. They also have intelligent early warning and fault diagnosis functions, which can detect and deal with potential safety hazards in time. Lithium battery cleaning equipment has a fast and stable transmission system, which can ensure the stability and safety of lithium batteries during the cleaning process.

Who are we?

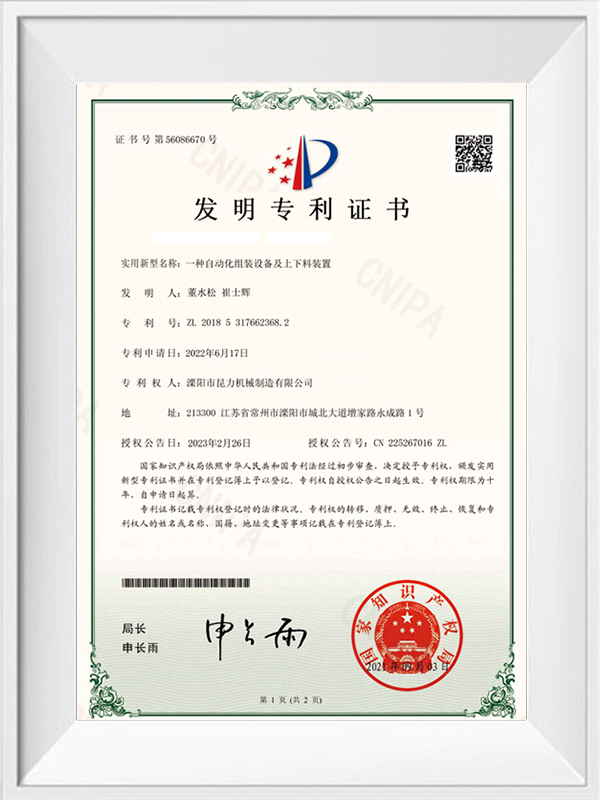

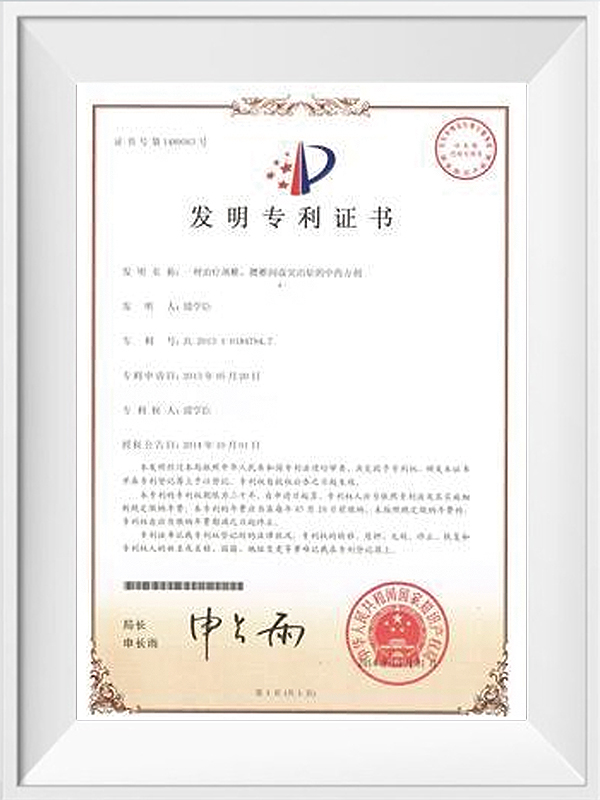

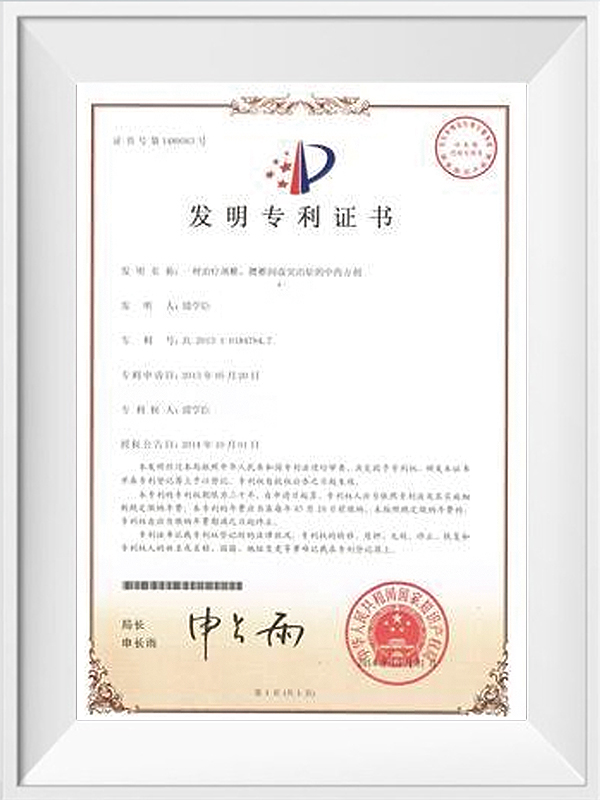

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China New Energy Lithium Battery Automation Equipment Suppliers and New Energy Lithium Battery Automation Equipment Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

How does the intelligent control system of new energy lithium battery automation equipment monitor and adjust the production process in real time?

The intelligent control system of new energy lithium battery automation equipment realizes real-time monitoring and adjustment of the production process by integrating advanced sensors, data processing units and algorithms.

1. Data acquisition and monitoring

Sensor network: A variety of sensors are deployed inside the equipment, such as temperature sensors, pressure sensors, current sensors, etc., to collect various parameter data in the production process in real time.

Data transmission: The collected data is transmitted to the central control unit by wired or wireless means to ensure the real-time and accuracy of the data.

2. Data processing and analysis

Data processing unit: After receiving the data, the central control unit quickly processes and analyzes the data through a high-performance data processing unit.

Algorithm application: Use advanced data analysis algorithms and machine learning algorithms to perform pattern recognition and trend prediction on key indicators in the production process.

3. Real-time monitoring

Visual interface: Through the human-computer interaction interface, operators can view the operating status of the production line, the changing trend of key parameters, etc. in real time.

Alarm system: When certain parameters exceed the preset safety range, the system will automatically trigger the alarm mechanism to remind the operator to take timely measures.

4. Automatic adjustment and optimization

Feedback control: Based on the results of real-time data analysis, the intelligent control system can automatically adjust the process parameters in the production process, such as temperature, pressure, speed, etc., to ensure the stability of the production process and the consistency of product quality.

Optimization algorithm: Use the optimization algorithm to optimize the production process, reduce production costs, and improve production efficiency.

5. Remote monitoring and maintenance

Remote access: Through the remote access function, technicians can remotely monitor the operating status of the equipment and perform necessary debugging and maintenance.

Fault diagnosis: The intelligent control system can automatically perform fault diagnosis and predictive maintenance, discover and solve potential problems in advance, and reduce the failure rate of equipment.

The intelligent control system of new energy lithium battery automation equipment realizes real-time monitoring and adjustment of the production process through functions such as data acquisition, processing, monitoring and automatic adjustment, ensuring the stability of the production process and the consistency of product quality.

How does high integration specifically improve the production efficiency of new energy lithium battery automation equipment?

High degree of integration plays a vital role in new energy lithium battery automation equipment. It significantly improves production efficiency by optimizing the equipment structure and integrating functional modules. The following are several aspects of how high integration specifically improves the production efficiency of new energy lithium battery automation equipment:

Reduce interruptions in the production process:

The high degree of integration closely connects multiple production links, reducing the transfer time and waiting time of materials on the production line, and reducing the frequency of interruptions in the production process. For example, by integrating automatic feeding systems, assembly equipment and testing devices, continuous production from raw materials to finished products is achieved, greatly improving production efficiency.

Optimize space layout:

The integrated design allows the equipment to complete more production tasks while occupying less space. This helps companies save production costs while improving the overall efficiency of the production line.

Reduce manual intervention:

Highly integrated equipment reduces the need for manual operations and makes the production process more automated and intelligent. This not only reduces labor costs, but also reduces the impact of human factors on production, improving production efficiency and product quality stability.

Improve production line flexibility:

Integrated equipment can quickly adjust production plans and production processes according to changes in market demand and product specifications. This flexibility enables companies to respond to market changes faster and improve market competitiveness.

Improve equipment reliability:

By optimizing the equipment structure and integrating functional modules, the stability and reliability of highly integrated equipment have been improved. This reduces equipment failures and downtime, further improving production efficiency.

High degree of integration has specifically improved the production efficiency of new energy lithium battery automation equipment by optimizing the production process, reducing manual intervention, improving the flexibility of the production line, and improving equipment reliability. This improvement is not only reflected in production speed, but also in product quality and stability, injecting strong impetus into the development of the new energy lithium battery industry.

English

English русский

русский عربى

عربى