Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom High Speed Circular Saw Machine

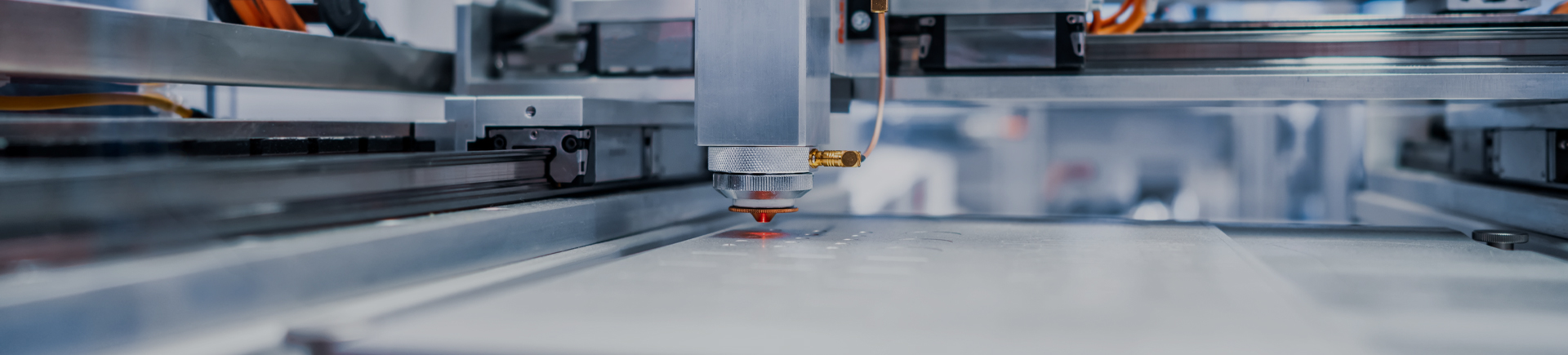

Fully automatic circular saw machines can be divided into two categories according to the cutting materials: one is used to cut metal, and the other is used to cut wood. Our circular saw machine is mainly used to cut metal.

Jiangsu Kunli Intelligent Manufacturing has always focused on the research and development, design and production of various types of sawing machines. It is a domestic manufacturer specializing in the manufacturing of CNC sawing machines. And it has won the market with its superb technology and has become a cutting equipment favored by the market. The company specializes in the production and sales of circular saw machines, saw blades and related services. Since its establishment, the company has adhered to the path of quality and efficiency development. Hire well-known senior engineers as technical consultants to continuously improve products. Kunli provides users with good product quality assurance and thoughtful services at reasonable prices, creating benefits for users, thus making Kunli products sell well all over the country and have been widely recognized by customers. Kunli products sell well at home and abroad and are deeply trusted by users. The company has sales and service outlets all over the country, strictly implements the ISO9001 international quality management system, and has always focused on technological innovation of products, which are characterized by high efficiency and low consumption.

Who are we?

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China High Speed Circular Saw Machine Suppliers and Fully Automatic Circular Saw Machine Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

Does the high-speed circular saw machine consider the adaptability of different materials or different cutting needs during the design process?

In the design process of the high-speed circular saw machine, the adaptability of different materials or different cutting needs will indeed be fully considered. This is because the high-speed circular saw machine, as a multifunctional and efficient cutting equipment, needs to meet the cutting needs of different industries and different materials.

The design of the high-speed circular saw machine will take into account the physical properties of different materials, such as hardness, toughness, density, etc. For different materials, designers will choose the appropriate saw blade material, size and tooth shape to ensure the stability and cutting quality during the cutting process. For example, for metal materials with higher hardness, carbide saw blades may need to be selected; while for soft materials such as wood, high-speed steel saw blades may be more suitable.

The design of the high-speed circular saw machine will also take into account the characteristics of different cutting needs. For example, for some applications that require high-precision cutting, such as aerospace, mold manufacturing and other fields, designers will pay special attention to the cutting accuracy and stability of the machine. To this end, they may use high-precision spindles, drive systems and control systems to ensure that the cutting accuracy meets the requirements. At the same time, for some applications that require high-efficiency cutting, such as metal recycling, sheet metal processing and other fields, designers may improve cutting efficiency by optimizing the cutting speed and feed speed of the machine.

The design of high-speed circular saws also takes into account the difficulty of cutting different materials and the service life of the machine. For some difficult-to-cut materials, designers may use more powerful drive systems and more durable saw blades to ensure a smooth cutting process. At the same time, in order to extend the service life of the machine, designers will also focus on the durability and maintainability of the machine, using wear-resistant materials, reasonable layout and easy-to-maintain design solutions.

The high-speed circular saw machine does fully consider the adaptability of different materials or different cutting needs during the design process to ensure that the machine can meet various complex and diverse cutting needs.

What role does the intelligent control system play in high-speed circular saw machines?

Intelligent control systems play a vital role in high-speed circular saw machines, and their impact is mainly reflected in the following aspects:

Automated operation and monitoring:

Through preset programs, the intelligent control system can realize the automatic start, stop, adjustment and monitoring of high-speed circular saw machines. This function greatly reduces the workload of operators and improves work efficiency.

Precise cutting control:

The system can automatically adjust the position and speed of the tool according to the required cutting size and shape to achieve precise cutting. This feature not only ensures product quality, but also reduces the risk of human error.

Material identification and parameter optimization:

The intelligent control system can automatically identify the type of workpiece material and automatically select the best cutting parameters according to the hardness and thickness of the material. This adaptive ability enables high-speed circular saw machines to handle a variety of different types of materials without human intervention.

Fault diagnosis and prevention:

When a system fails, the intelligent control system can quickly issue a sound signal or other alarm to prompt the user to check and repair. At the same time, it can also monitor the operating status of the machine in real time, predict possible problems, and take measures in advance to prevent the occurrence of failures.

Data recording and analysis:

The system can record various numerical information in the working process in the form of reports, which is convenient for users to analyze data. Through these data, users can understand the performance, efficiency and potential optimization space of the machine.

Remote monitoring and management:

The intelligent control system supports remote monitoring and management functions. Users can view the operating status and production progress of the machine anytime and anywhere through the Internet. This flexibility enables users to better manage production resources and improve production efficiency.

The intelligent control system plays multiple roles in high-speed circular saw machines, including automated operation, precise control, material identification, fault diagnosis, data recording and remote monitoring, providing strong support for the performance improvement and production efficiency optimization of high-speed circular saw machines.

English

English русский

русский عربى

عربى