Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Automatic Carrier Tape Forming Machine

The carrier tape forming machine is a mechanical device that presses roll-shaped film material into a carrier tape box with a specific width and depth. It is widely used in microelectronics, semiconductors, electronic components and other industries. The carrier tape forming machine has production speed and can complete a large amount of carrier tape forming work in a short time; the carrier tape forming machine can ensure extremely high precision, so that the formed carrier tape can meet the strict requirements of customers and ensure the quality of the product. Quality and stability; the equipment has stable performance and can maintain stable molding quality and efficiency under long-term continuous operation, reducing production interruptions caused by equipment problems; the operation of the carrier tape forming machine is relatively simple, and the loading and unloading of the mold Adjustments are very convenient, making it easy for operators to get started.

Who are we?

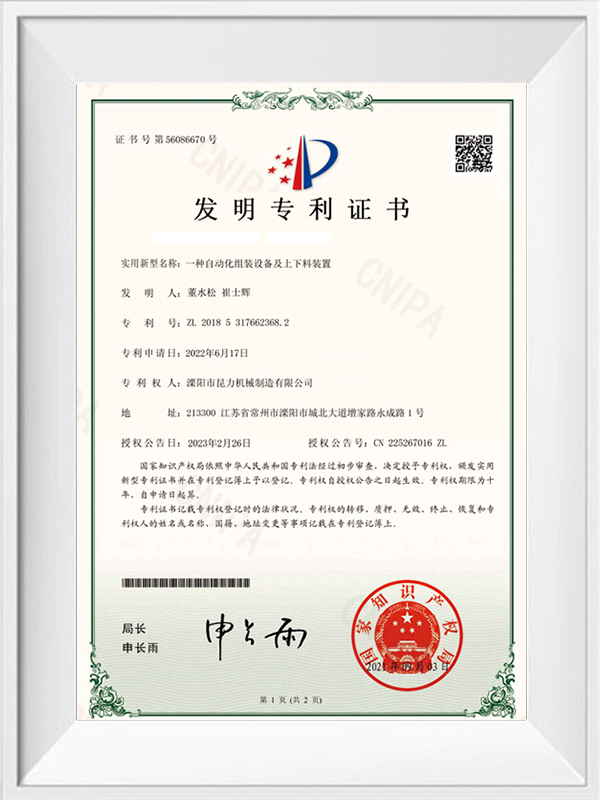

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Automatic Carrier Tape Forming Machine Suppliers and Automatic Carrier Tape Forming Machine Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

How do tape forming machine manufacturers ensure that tape forming machines can achieve accurate positioning and forming during high-speed production?

Advanced forming mold design:

The forming mold is a key component of the tape forming machine, which determines the shape, size and quality of the finished product. Manufacturers will use high-precision processing technology to ensure the accuracy and durability of the mold.

The fluidity of the material and the shrinkage rate after forming will be considered during the design to achieve a more accurate forming effect.

High-precision positioning system:

Manufacturers will use high-speed precision positioning platform technology, such as linear motor direct drive technology, to achieve fast and accurate positioning.

The positioning system needs to have high speed, high acceleration, high positioning accuracy and stability to ensure accurate forming and positioning during high-speed production.

Advanced control system:

The control system is the core of the tape forming machine, responsible for monitoring and controlling the entire forming process.

Manufacturers will use advanced control algorithms and sensor technology to monitor and adjust the temperature, pressure, speed and operating status of each mechanism in the forming process in real time to ensure the stability and accuracy of the forming process.

Cooling device and temperature control:

The cooling device is a key part to ensure product quality and performance. Manufacturers will use effective cooling methods, such as water cooling or air cooling, to control the temperature and shape stability of the product after molding.

The temperature control system will monitor and adjust the temperature during the molding process in real time to ensure that the material is molded within the optimal temperature range.

Raw material quality control:

The quality of raw materials directly affects the performance and quality of the finished product. Manufacturers will strictly screen and test raw materials to ensure that they meet production requirements.

Regular maintenance and calibration:

Manufacturers will formulate regular maintenance and calibration plans to ensure the stability and accuracy of the equipment.

Maintenance includes routine operations such as cleaning, lubrication, and tightening, as well as advanced operations such as replacing worn parts and calibrating equipment accuracy.

What are the recommendations of carrier forming machine suppliers when the equipment fails or requires maintenance?

Daily maintenance:

Daily maintenance is the center of cleaning, tightening, adjustment and lubrication.

Daily maintenance should be performed during work and after receiving the machine before each shift.

This work should be done independently by the operator of the stainless steel spring sheet forming machine.

Regular maintenance:

According to the maintenance requirements of mechanical equipment, regular inspections are carried out after the specified working hours or mileage.

Regular maintenance should include sealing, repair, deactivation repair, walking and maintenance, and seasonal maintenance.

Professional maintenance suggestions:

For some complex faults, it is recommended to seek the help of professional technicians to ensure the quality and efficiency of the maintenance.

Fault handling:

For different types of faults, such as nozzle blockage, temperature control failure, transmission system failure and mold damage, the supplier will provide corresponding maintenance methods.

For example, nozzle blockage can be solved by cleaning or replacing the nozzle; temperature control failure requires checking the temperature control instrument and cleaning the radiator; transmission system failure requires checking components such as motors, reducers and chains; mold damage may need to be repaired or replaced.

English

English русский

русский عربى

عربى