Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Non-Standard Automation In Chemical Industry

Who are we?

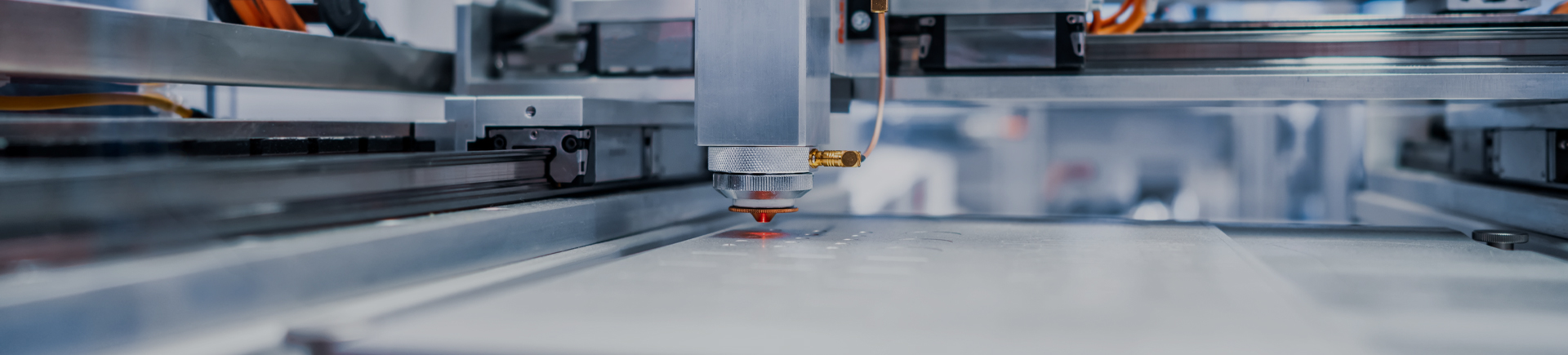

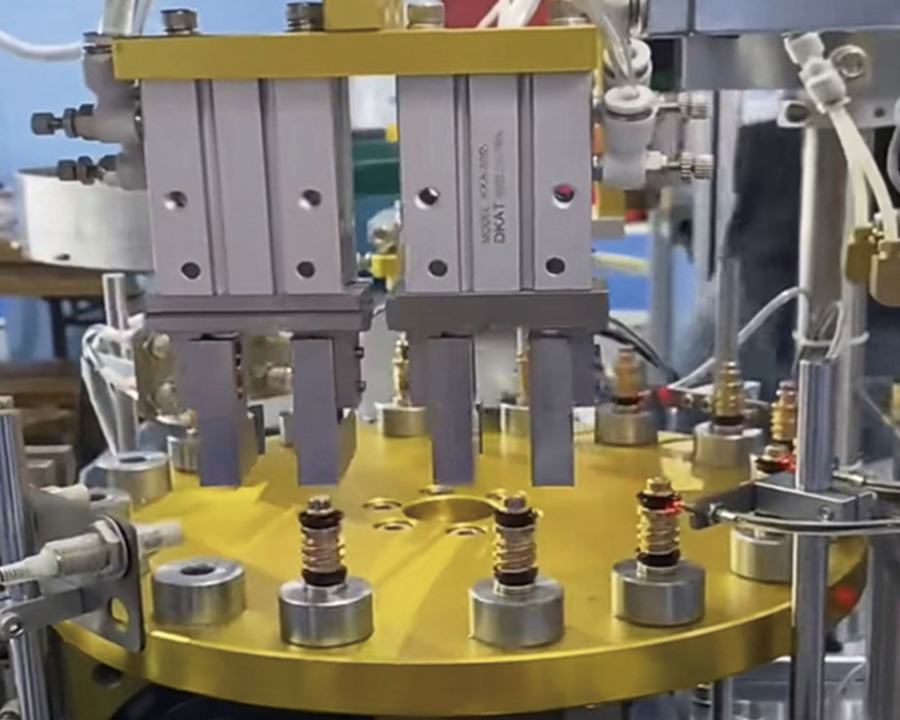

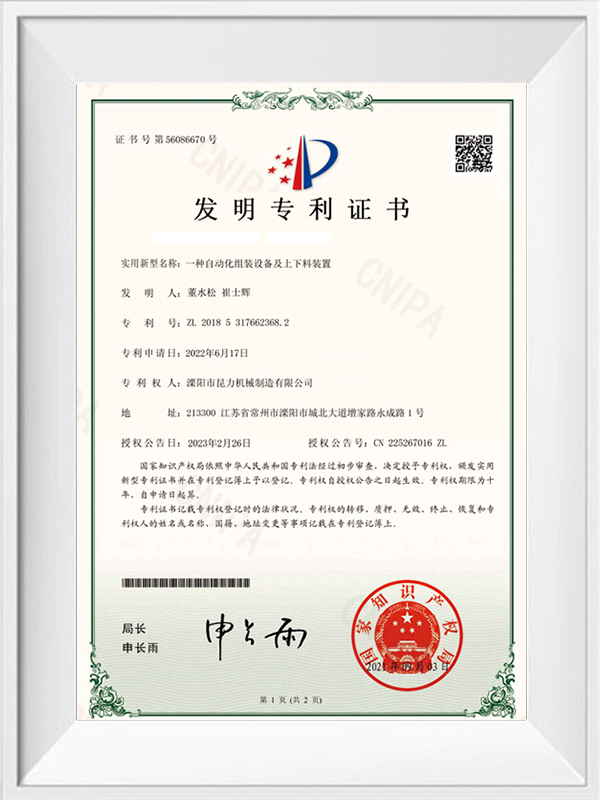

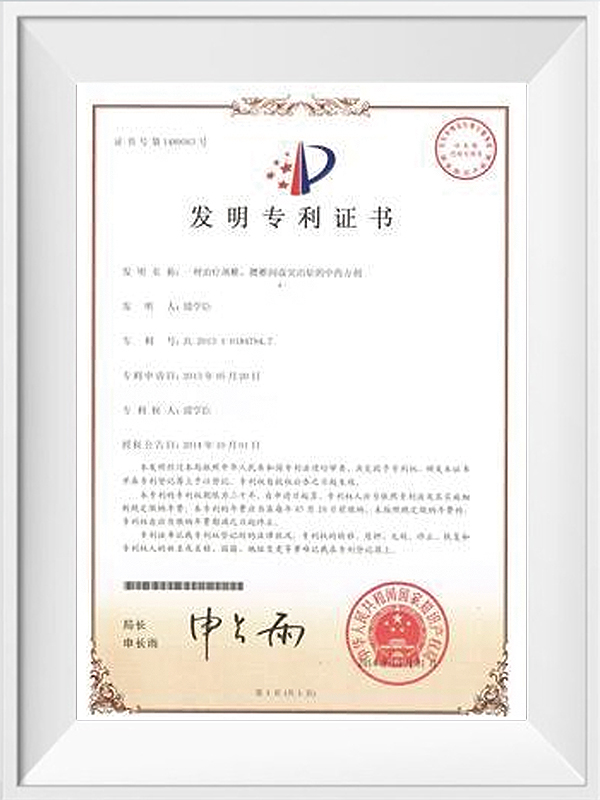

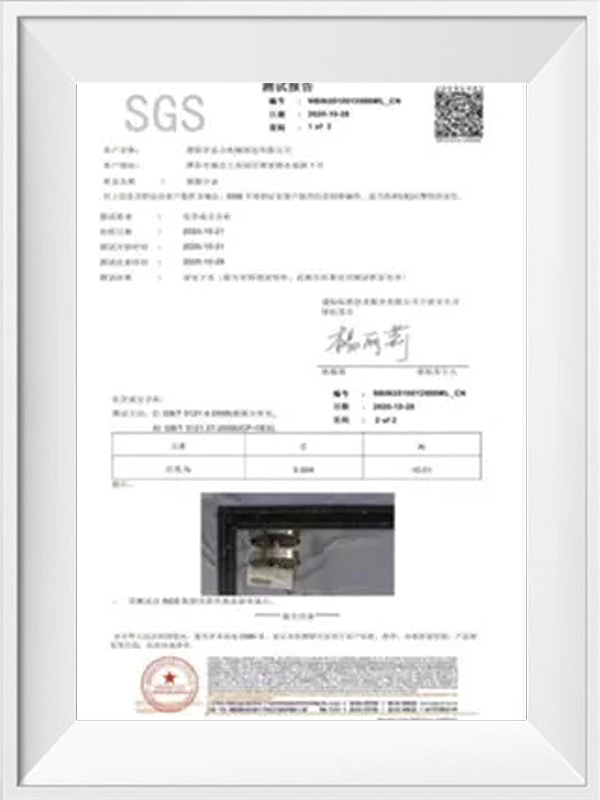

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Non-Standard Automation In Chemical Industry Suppliers and Non-Standard Automation In Chemical Industry Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

What are the main application areas of non-standard automation in the chemical industry?

The main application areas of non-standard automation in the chemical industry are wide and diverse to meet the special needs of the chemical industry. Here are some of the main application areas:

Production process automation:

Chemical reactor: Non-standard automation equipment can accurately control parameters such as reaction temperature, pressure, stirring speed, etc. to ensure the stability and safety of chemical reactions.

Separation and purification: Including processes such as distillation, extraction, crystallization, and filtration, non-standard automation equipment can achieve precise process control and product quality assurance.

Mixing and homogenization: In response to the requirements of mixing different materials, non-standard automation equipment provides customized solutions to achieve uniform mixing of materials and product quality control.

Packaging and palletizing automation:

Automated packaging line: Non-standard automation equipment can customize automated packaging systems according to the packaging requirements of different products, such as liquids, powders, granules, etc., to improve packaging efficiency and accuracy.

Palletizing robot: In response to the stacking needs of chemical products, non-standard automation equipment designs special palletizing robots to achieve automated stacking, reduce labor costs and improve safety.

Material conveying and warehousing automation:

Conveying system: Non-standard automation equipment designs various conveying systems, such as belt conveying, chain conveying, roller conveying, etc., to realize the automated conveying of chemical raw materials, intermediates and finished products.

Warehouse management system: Combined with automated stereoscopic warehouses, forklifts, AGV carts and other equipment, realize the automated storage, management and scheduling of chemical products.

Environmental protection and safety automation:

Waste gas treatment system: Non-standard automation equipment designs waste gas treatment systems, such as adsorption, catalytic combustion, desulfurization and denitrification, etc., to achieve standard discharge of chemical waste gas.

Wastewater treatment system: According to the characteristics of chemical wastewater, non-standard automation equipment provides customized wastewater treatment solutions to ensure the effect of wastewater treatment.

Safety monitoring system: Including fire alarm, gas leak detection, emergency stop and other safety monitoring systems to ensure the safety of chemical production.

Quality control and testing automation:

Online analyzer: Non-standard automation equipment designs online analyzer to monitor key parameters in the chemical production process in real time, such as temperature, pressure, concentration, etc., to ensure product quality.

Laboratory automation: Combine automation equipment, software and data analysis to realize automated processing, testing and data analysis of laboratory samples.

Special process automation:

High temperature and high pressure process: For chemical production under high temperature and high pressure environment, non-standard automation equipment provides high temperature and high pressure resistant equipment and system solutions.

Hazardous chemical handling: For the production, storage and transportation of hazardous chemicals, non-standard automation equipment provides safe handling and protection measures.

English

English русский

русский عربى

عربى