Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Non-Standard Automated Production Lines For The Automotive Industry

Who are we?

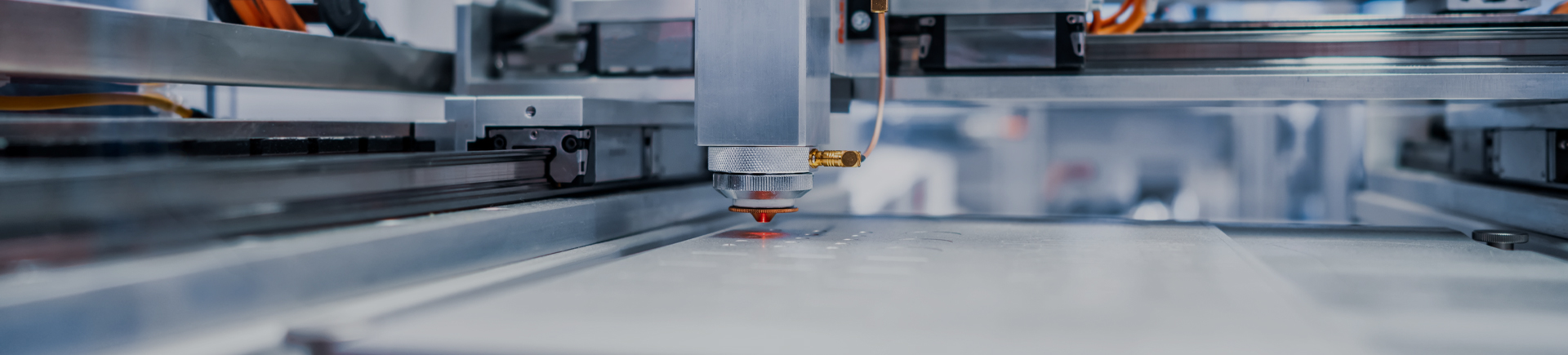

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Non-Standard Automated Production Lines For The Automotive Industry Suppliers and Non-Standard Automated Production Lines For The Automotive Industry Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

How to reduce the cost of non-standard automated production lines by optimizing the design and production process?

In the automotive industry, non-standard automated production lines are favored for their high degree of customization and flexibility. However, compared with traditional standardized production lines, the cost of non-standard automated production lines is often higher.

1. Deeply understand the needs and achieve precise design

The biggest feature of non-standard automated production lines is their high degree of customization, which means that each production line is designed according to the specific needs of customers. This customization is not only reflected in the overall layout of the production line, equipment selection, process flow, etc., but also in every detail. For example, every fixture, every sensor, and even every screw on the production line may be customized according to the specific needs of customers. This high degree of customization makes each non-standard automated production line unique and can meet the production needs of customers to the greatest extent.

In the design stage, make full use of modern design methods and tools such as CAD, CAE, CAM, etc. to improve design efficiency and quality. At the same time, pay attention to the modularization, standardization and serialization of the design, so that each module and component in the production line can be easily replaced and upgraded, reducing the maintenance cost in the later stage.

2. Optimize the production process and improve production efficiency

The optimization of the production process is the key to improving the production efficiency of Non-Standard Automated Production Lines For The Automotive Industry. First of all, we must conduct a comprehensive analysis of the production process, find out the bottleneck links and waste links, and improve the overall efficiency of the production line by improving the process, optimizing the layout, and introducing automated equipment.

Pay attention to quality control in the production process. By introducing advanced quality inspection equipment and means, ensure that the product quality of the production line meets customer requirements. At the same time, we must establish a complete quality management system, conduct a comprehensive monitoring of the production process, and promptly discover and solve problems.

3. Reduce material costs and select equipment reasonably

Material cost is an important part of the cost of non-standard automated production lines. When selecting materials, we must fully consider factors such as material performance, price, and processability, and select cost-effective materials. At the same time, we must pay attention to the recyclability and environmental protection of materials to reduce pollution to the environment.

In terms of equipment selection, we must reasonably select equipment models and quantities according to the actual needs of the production line. Avoid the waste of investment caused by blindly pursuing high-end equipment. At the same time, we must pay attention to the stability and reliability of equipment to reduce the later maintenance costs.

4. Strengthen supply chain management and reduce procurement costs

The manufacturing process of Non-Standard Automated Production Lines For The Automotive Industry involves a large number of parts and raw material purchases. It is necessary to strengthen supply chain management, establish long-term and stable cooperative relationships with suppliers, and ensure the quality and stable supply of parts and raw materials. At the same time, it is necessary to focus on reducing procurement costs and reduce procurement costs through centralized procurement, price comparison procurement, etc.

5. Cultivate professional talents and improve management level

To reduce the cost of Non-Standard Automated Production Lines For The Automotive Industry, it is also necessary to cultivate a professional team of technical and management talents. Through training and learning, improve the professional skills and innovation capabilities of technicians so that they can better cope with complex design and production tasks. At the same time, it is necessary to strengthen the construction of the management team, improve the management level, and ensure the normal operation and cost control of the production line.

English

English русский

русский عربى

عربى