Amid the industrialization of third-generation semiconductor materials, silicon carbide (SiC) has be...

READ MOREProduct Series

- - Standard Automated Production Line

-

- Non-Standard Automated Production Line

- - Non-Standard Automated Production Line For Industrial Electrical Appliance Industry

- - Energy Storage Automated Production Line

- - Non-Standard Automated Production Lines For The Automotive Industry

- - Non-Standard Automated Production Line For Food And Beverage Industry

- - Non-Standard Automation In Chemical Industry

- - Non-Standard Automated Production Line For Home Appliance Industry

- - Automated Production Line For Hardware And Building Materials Industry

- - Non-Standard Automated Production Line For New Energy Industry

- - Non-Standard Automated Production Lines For The Consumer Electronics Industry

Custom Non-Standard Automated Production Line For Home Appliance Industry

Who are we?

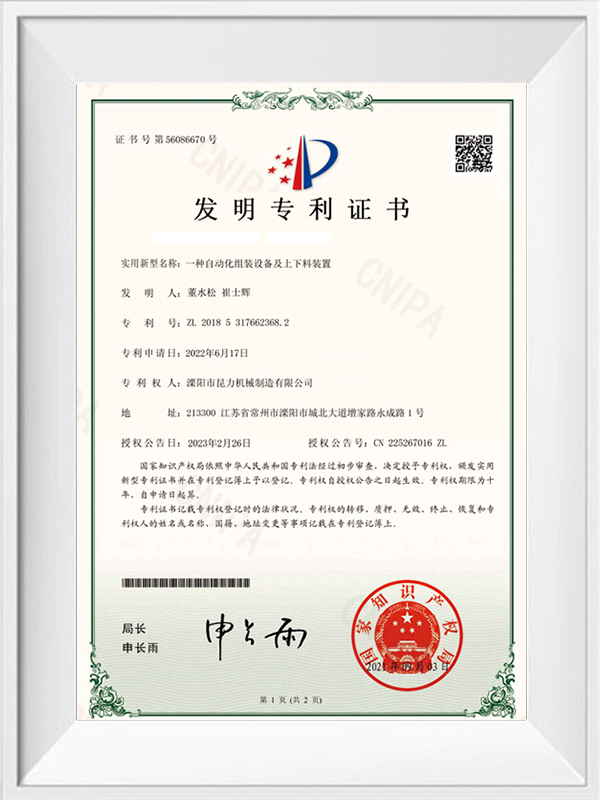

Established in 2013, Liyang Kunli Machinery Manufacturing Co., Ltd is a scientific and technological enterprise specializing in the R&D, transformation and production of industrial automation equipment and non-standard automation equipment. We are China Non-Standard Automated Production Line For Home Appliance Industry Suppliers and Non-Standard Automated Production Line For Home Appliance Industry Manufacturers. Equipped with dozens sets of precision machining equipment for machining, cutting and welding,etc, the company now has more than 20 design engineers, 5 software and PLC electrical engineers, 3 inspectors, and 16 key CNC technicians. Kuli company has been engaging in the innovation of automatization technology and solution to automatization, so as to promote the progress of the technology of smart factories, non-standard equipment and automated assembly lines. The company has made many technological breakthroughs and achieved success in the projects of high precision equipment, unmanned smart factories, etc, in the course of many years’research and development, and therefore a good range of high-tech, high-precision, cutting-edge products have been designed, developed and produced. The scope of R&D includes the following area: 1. Unmanned smart factories, flexible automation lines, non-standard auto equipment; the design and production of non-standard automatization of assembly lines, intelligent storage, stacking, palletizing and transportation, etc. 2. Stirring, coating, coiling, soft pack sealing, Lithium battery cleaning and assembling in the industry of new energy lithium battery and energy storage; the production process of automatization of energy storage assembly lines, etc. 3. The design of inspection robots(inspection of safe production, fire and water prevention, malfunction of equipment, etc), unmanned automated patrol scheme and relevant turn-key projects. 4. The integrated design of automatization of CCD vision . 5. The design of automatization scheme of AGV handling and integration projects. 6. The design of non-standard customized equipment, special equipment and automation production lines and relevant turn-key projects. Kunli company has been devoting to the R&D and innovation of high precision, cutting-edge equipment for more than a decade, and has accumulated rich technological experience in R&D and manufacture.

-

Advanced Plant Ared

0㎡+ -

Founded In

0 -

Designers

0+ -

Technical Backbone

0+

-

-

Accurately measuring an object's tilt is crucial in many industries, and inclinometers shoulder this...

READ MORE -

The efficient transmission and distribution of electricity is crucial in the vast networks of modern...

READ MORE -

Amidst accelerating globalization and the increasing frequency of various activities, market demand ...

READ MORE -

Grinding plays a crucial role in numerous modern industrial production processes. This is particular...

READ MORE

What are the main features of Non-Standard Automated Production Line For Home Appliance Industry?

The main features of Non-Standard Automated Production Line For Home Appliance Industry include:

High customization:

This type of production line is designed and manufactured specifically for the home appliance industry and can be highly customized according to the production requirements, specifications and processes of different home appliance products.

Customized production lines can better adapt to the production characteristics of products and improve production efficiency and product quality.

Flexibility:

Because it is a non-standardized production line, its design is usually highly flexible and can be quickly adjusted according to product changes or market demand.

This flexibility enables the production line to adapt to rapid changes in the market and reduce the cost of replacing the production line due to product updates or upgrades.

Efficiency:

The application of automation technology enables the production line to achieve continuous and high-speed production, reduce manual operations, and improve production efficiency.

The operating efficiency of the production line is further improved by optimizing the production process and reducing unnecessary downtime.

Intelligence:

The introduction of advanced control systems and sensor technology enables the production line to have the ability of intelligent monitoring and management.

Intelligent technology can monitor the operating status of the production line in real time, automatically adjust production parameters, and ensure the stability and reliability of the production process.

Modular design:

The modular design concept is adopted to divide the production line into several relatively independent modules or units.

This design makes the production line easier to maintain, upgrade and expand, reduces maintenance costs and increases the service life of the production line.

Energy saving and environmental protection:

Focus on energy saving and emission reduction, use energy-saving equipment and environmentally friendly materials to reduce energy consumption and environmental pollution in the production process.

By optimizing the production process and introducing clean energy, the environmental impact of the production line can be further reduced.

Integration:

Integrate multiple production links into one production line to achieve continuity and automation of the production process.

Integrated design can reduce the cost of material handling and storage and improve the overall operating efficiency of the production line.

Reliability and stability:

The production line has been rigorously designed and tested to ensure high reliability and stability during long-term operation.

By introducing redundant design and fault warning system, the failure rate and downtime of the production line can be further reduced.

How does Non-Standard Automated Production Line For Home Appliance Industry meet the needs of customized and personalized production?

In terms of meeting the needs of customized and personalized production, Non-Standard Automated Production Line For Home Appliance Industry mainly achieves this through the following aspects:

High customization capability:

Modular design: The production line adopts modular design, so that each production link can be quickly combined and adjusted according to customer needs. This design method not only improves the flexibility of the production line, but also greatly shortens the production preparation time.

Flexible manufacturing technology: Flexible manufacturing technology enables the production line to easily cope with the needs of multi-variety small batch production. By flexibly adjusting production parameters and process flow, it can quickly switch to the production of different products to meet the personalized needs of customers.

Quick response mechanism:

Quick adjustment: The production line has the ability to adjust quickly, and can complete the reconfiguration and debugging of the production line in a short time to ensure the delivery of customized products on time.

Customized service: Provide customized services to customers, including product design, process planning, production scheduling, etc., to ensure that products from design to production can meet the personalized needs of customers.

Intelligent and information technology:

Intelligent scheduling system: Introduce an intelligent scheduling system to automatically adjust the production plan according to customer needs and the actual situation of the production line to ensure production efficiency and product quality.

Data-driven decision-making: By collecting and analyzing production data, data support is provided for customized production, helping enterprises to better predict market demand, optimize production processes and improve product quality.

Non-Standard Automated Production Line For Home Appliance Industry can meet the needs of customized and personalized production through modular design, flexible manufacturing technology, rapid response mechanism, and the application of intelligent and information technology, and provide customers with high-quality and efficient customized products.

English

English русский

русский عربى

عربى