Wire Harness Machines: The Unseen Force Behind Modern Electronics

I. Introduction

Have you ever stopped to consider the intricate network of wires that powers your car, keeps your refrigerator running, or enables your smartphone to function seamlessly? Hidden beneath the sleek exteriors of countless everyday electronics lies a complex, organized system of cables known as a wire harness. These unsung heroes are crucial for transmitting power, data, and signals, ensuring the safe and efficient operation of virtually every electronic device we use.

But how are these elaborate bundles of wires created with such precision and consistency? The answer lies with the wire harness machine. A wire harness machine is a sophisticated piece of industrial equipment designed to automate and streamline the manufacturing process of wire harnesses. From cutting and stripping wires to crimping terminals and assembling connectors, these machines play a pivotal role in transforming raw materials into the vital arteries of modern technology.

In today's fast-paced manufacturing landscape, the demand for high-quality, reliable, and cost-effective wire harnesses is ever-increasing. Wire harness machines are at the forefront of meeting this demand, offering unparalleled efficiency, precision, and versatility. This article will delve into the world of wire harness machines, exploring their fundamental components, operational mechanisms, diverse applications, and the transformative benefits they bring to various industries.

II. The Basics of Wire Harnesses

At its core, a wire harness is an organized assembly of wires, cables, and often other components like connectors, terminals, and protective coverings, designed to transmit electrical power or signals.

A. Components of a Wire Harness

| Component | Description |

|---|---|

| Wires | These are the conduits for electrical current or data. They come in various types (e.g., stranded, solid), gauges (thickness), and insulation materials, chosen based on the application's voltage, current, and environmental requirements. |

| Connectors | Devices that join electrical circuits, allowing for easy connection and disconnection. They vary widely in shape, size, pin count, and locking mechanisms, tailored for specific interfaces (e.g., automotive, data, power). |

| Terminals | Metal components crimped or soldered to the end of a wire, enabling it to be connected to a connector or other electrical point. Common types include ring terminals, spade terminals, and pin terminals. |

| Tapes, Conduits, and Protective Coverings | Materials like electrical tape, braided sleeving, corrugated tubing, or heat shrink tubing are used to bundle wires, provide abrasion resistance, protect against moisture, and offer insulation. |

B. Why are Wire Harnesses Essential?

Wire harnesses are far more than just bundles of wires; they are critical for:

- Organization and Space-saving: They consolidate numerous individual wires into a single unit, making installation neater, more efficient, and optimizing space within complex systems.

- Protection from Environmental Factors: The protective coverings shield wires from heat, cold, abrasion, moisture, chemicals, and vibrations, extending their lifespan and ensuring reliability.

- Ease of Installation and Maintenance: A pre-assembled harness simplifies the installation process, reducing errors and saving time. It also makes troubleshooting and maintenance more straightforward.

- Ensuring Electrical Integrity and Safety: By precisely routing and securing wires, harnesses prevent short circuits, reduce electromagnetic interference (EMI), and ensure consistent electrical performance, which is paramount for safety.

III. Types of Wire Harness Machines

Wire harness machines come in various forms, each specializing in a particular stage of the manufacturing process, or integrating multiple functions for higher automation.

A. Categorization by Function

| Machine Type | Description |

|---|---|

| Cutting and Stripping Machines | These are fundamental.

|

| Crimping Machines | Used to attach terminals to the stripped ends of wires.

|

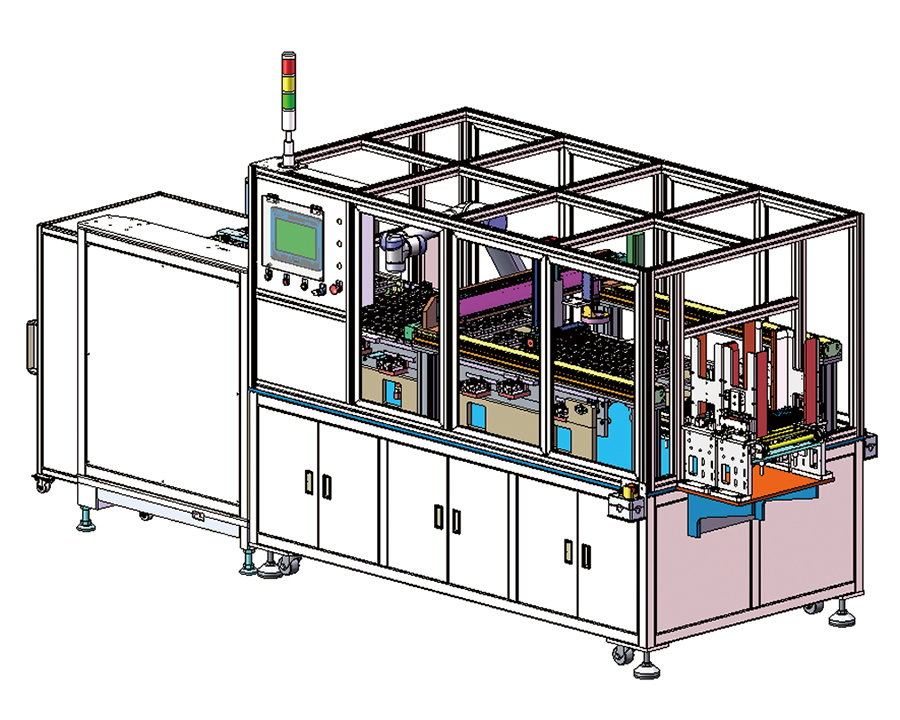

| Terminal Insertion Machines | After terminals are crimped, these machines automatically or semi-automatically insert the crimped terminals into the correct cavities of a connector housing. |

| Taping and Bundling Machines | These machines wrap the assembled wires with various tapes (e.g., PVC, cloth, self-amalgamating) or apply protective conduits, creating the final bundled harness. |

| Testing Machines | Essential for quality control.

|

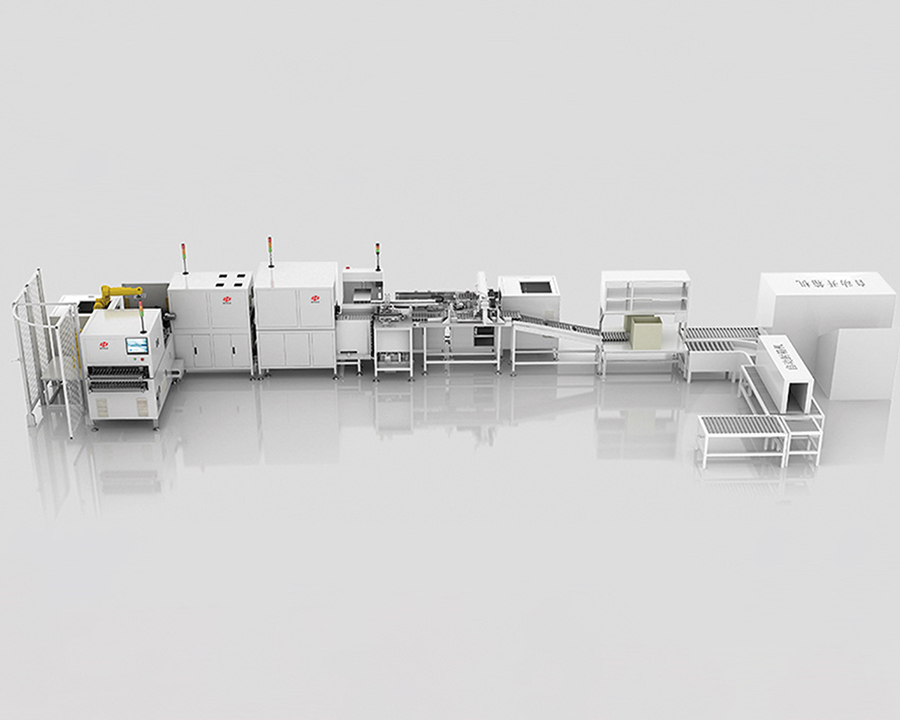

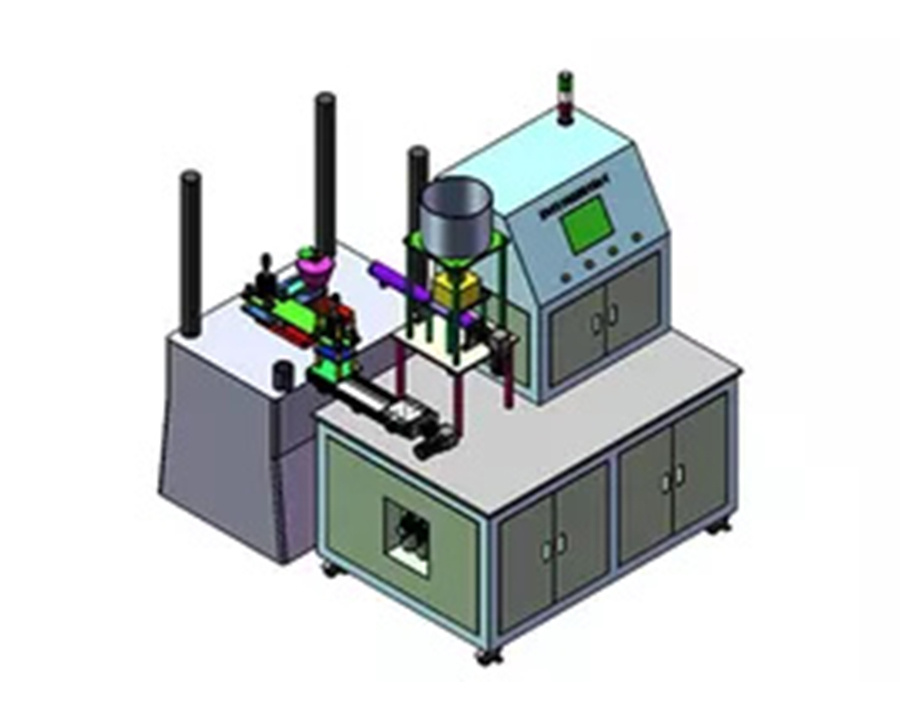

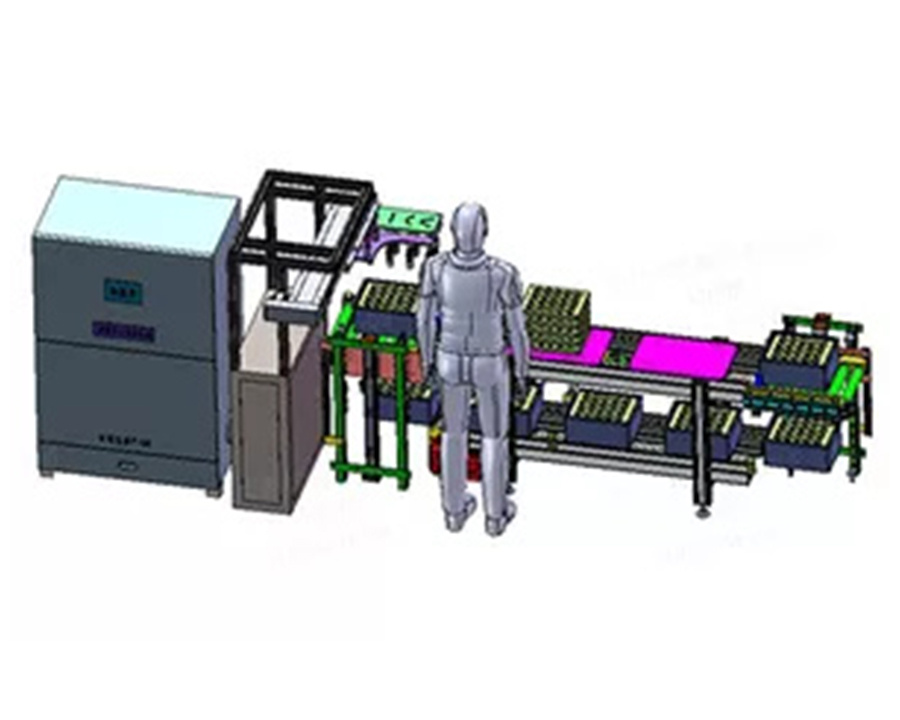

B. Integrated vs. Standalone Systems

Manufacturers can choose between standalone machines for specific tasks or integrated systems that combine multiple functions (e.g., cut-strip-crimp machines) into one automated line, offering higher throughput and reduced manual handling.

C. Specialized Machines

Some machines are designed for very specific applications, such as processing coaxial cables, flat ribbon cables, or handling extremely small wires for microelectronics, or large gauge wires for heavy-duty industrial applications.

IV. Key Components and Technologies

The precision and efficiency of wire harness machines are due to their sophisticated internal components and integrated technologies.

| Component/Technology | Role |

|---|---|

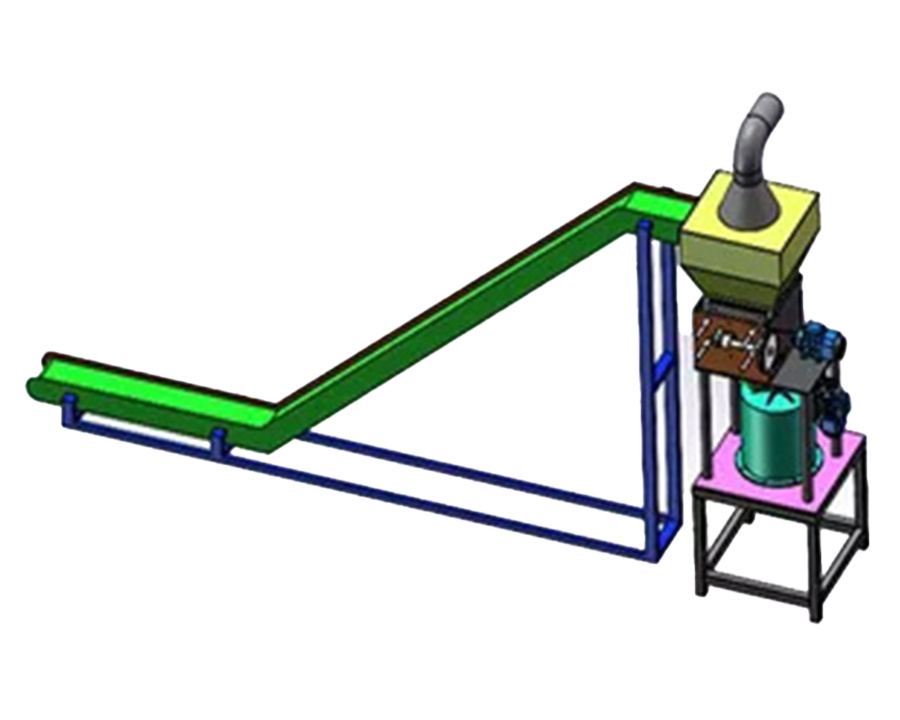

| Feeding Systems | These systems, including wire reels and dereelers, ensure a smooth and consistent supply of wire to the machine, preventing tangles and tension issues. |

| Measuring and Cutting Units | Equipped with highly accurate sensors and cutting blades, these units precisely measure the desired wire length and make clean, burr-free cuts. |

| Stripping Blades and Mechanisms | Specialized blades remove insulation without damaging the wire conductor. Different blade types and stripping mechanisms are used for various wire gauges and insulation materials. |

| Crimping Applicators and Dies | These are precision tools that form the terminal around the wire conductor, ensuring a secure and electrically sound connection. The correct die set is crucial for each terminal type. |

| Vision Systems | Increasingly common, vision systems use cameras and image processing software to inspect wire ends, crimp quality, and terminal insertion, identifying defects in real-time and improving quality control. |

| Software and Automation | Programmable Logic Controllers (PLCs) and user-friendly software interfaces control machine operations, allowing for precise programming of wire lengths, stripping depths, and crimping parameters. This enables rapid changeovers and complex harness configurations. |

| Safety Features | Modern machines incorporate numerous safety features, including safety guards, emergency stop buttons, and interlocks, to protect operators during use. |

V. How Wire Harness Machines Work (The Manufacturing Process)

The creation of a wire harness is a multi-step process, largely automated by these specialized machines.

A. Wire Feeding and Measuring

A wire reel feeds the wire into the machine. A precise encoder measures the exact length required for each segment of the harness.

B. Wire Cutting

Once the desired length is measured, a sharp blade cuts the wire cleanly.

C. Wire Stripping

The machine then precisely removes a specified length of insulation from one or both ends of the cut wire, exposing the conductor for termination.

D. Terminal Crimping

The stripped wire end is fed into a crimping applicator, which uses a die set to mechanically deform a terminal around the conductor, creating a strong electrical and mechanical connection. This can be done on one or both ends.

E. Seal Insertion (if applicable)

For harnesses requiring environmental protection, seals might be automatically or manually inserted onto the wire before crimping.

F. Connector Assembly

Crimped wires with terminals are then inserted into the appropriate cavities of a connector housing. This step can be manual for complex harnesses or automated for simpler ones.

G. Taping/Bundling

The assembled wires are then bundled together using electrical tape, braided sleeving, or corrugated tubing to form the final harness structure, providing protection and organization.

H. Testing and Quality Control

Finally, the completed wire harness undergoes rigorous testing (continuity, insulation, functional) to ensure it meets all electrical and mechanical specifications and is free from defects.

VI. Applications Across Industries

Wire harness machines are indispensable across a vast array of industries, underpinning the functionality of diverse products.

| Industry | Application of Wire Harnesses |

|---|---|

| Automotive | Perhaps the largest consumer, the automotive industry relies heavily on wire harnesses for engine management systems, interior lighting, infotainment, safety features (ABS, airbags), and power distribution throughout the vehicle. |

| Aerospace and Defense | In critical applications like avionics, flight control systems, and military equipment, wire harnesses must meet stringent reliability and performance standards, often operating in extreme environments. |

| Electronics | From consumer electronics like televisions and computers to industrial control panels and network equipment, wire harnesses provide the internal wiring infrastructure. |

| Medical Devices | Precision and reliability are paramount in medical equipment. Wire harnesses are found in diagnostic machines, surgical tools, patient monitoring systems, and more. |

| Telecommunications | Harnesses are vital for connecting components in communication infrastructure, including base stations, data centers, and network devices. |

| Home Appliances | Everyday appliances such as washing machines, refrigerators, ovens, and vacuum cleaners utilize wire harnesses for their internal electrical connections. |

| Industrial Machinery | Robotics, factory automation equipment, and heavy machinery all depend on robust wire harnesses for power and control signal transmission. |

VII. Benefits of Using Wire Harness Machines

The adoption of wire harness machines offers significant advantages to manufacturers.

| Benefit | Explanation |

|---|---|

| Increased Production Efficiency and Speed | Automation drastically reduces the time required to produce harnesses compared to manual methods, leading to higher output. |

| Enhanced Precision and Accuracy | Machines perform tasks with consistent precision, minimizing human error in cutting, stripping, and crimping, which is critical for product quality. |

| Improved Product Quality and Reliability | Consistent processes result in uniform harnesses with reliable electrical connections, reducing defects and ensuring long-term performance. |

| Reduced Labor Costs | Automation lessens the reliance on manual labor for repetitive tasks, allowing human resources to be allocated to more complex or supervisory roles. |

| Minimized Material Waste | Precise measurements and controlled processes reduce scrap material, leading to cost savings. |

| Greater Safety for Operators | Automated machines reduce the need for operators to handle sharp tools or perform repetitive motions, improving workplace safety. |

| Scalability and Flexibility in Production | Machines can be programmed for different harness configurations, allowing manufacturers to quickly adapt to changing product demands and scale production up or down as needed. |

VIII. Factors to Consider When Choosing a Wire Harness Machine

Selecting the right wire harness machine is a strategic decision that impacts production efficiency and product quality.

| Factor | Consideration |

|---|---|

| Production Volume and Throughput Requirements | The anticipated volume of harnesses needed will dictate the level of automation and speed required from the machine. |

| Wire Types and Sizes | Ensure the machine can handle the specific range of wire gauges, insulation materials, and types (e.g., single core, multi-core, shielded) used in your products. |

| Terminal and Connector Types | The machine must be compatible with the specific terminals and connectors you intend to use, often requiring specialized applicators and dies. |

| Level of Automation Desired | Consider whether semi-automatic machines suffice for lower volumes or if a fully automatic, integrated system is necessary for high-volume production. |

| Budget and ROI | Evaluate the initial investment cost against the long-term benefits in terms of increased efficiency, reduced labor, and improved quality to determine the return on investment. |

| Machine Footprint and Space Availability | Assess the physical size of the machine and ensure it fits within your manufacturing facility's layout. |

| Supplier Support, Service, and Spare Parts | Reliable after-sales support, readily available spare parts, and technical assistance are crucial for minimizing downtime. |

| Software Integration and User-Friendliness | An intuitive user interface and compatibility with existing manufacturing execution systems (MES) can greatly enhance operational efficiency. |

IX. Maintenance and Troubleshooting

Proper maintenance is key to ensuring the longevity and optimal performance of wire harness machines.

| Aspect | Description |

|---|---|

| Regular Cleaning and Lubrication | Preventative cleaning removes debris and wire particles, while proper lubrication reduces wear on moving parts. |

| Blade and Die Replacement | Cutting blades and crimping dies wear out over time and must be regularly inspected and replaced to maintain precision and quality. |

| Calibration and Adjustment | Periodic calibration ensures that measurements, stripping depths, and crimping forces remain accurate. |

| Common Issues and Solutions | Operators should be trained to identify and address common issues such as wire slippage, inconsistent strip lengths, or poor crimps, often by adjusting machine settings or replacing worn parts. |

| Importance of Preventative Maintenance | Following a strict preventative maintenance schedule significantly reduces the likelihood of unexpected breakdowns, extends machine lifespan, and ensures consistent output. |

X. Future Trends and Innovations

The wire harness machine industry is continually evolving, driven by demands for greater efficiency, intelligence, and sustainability.

| Trend | Impact/Description |

|---|---|

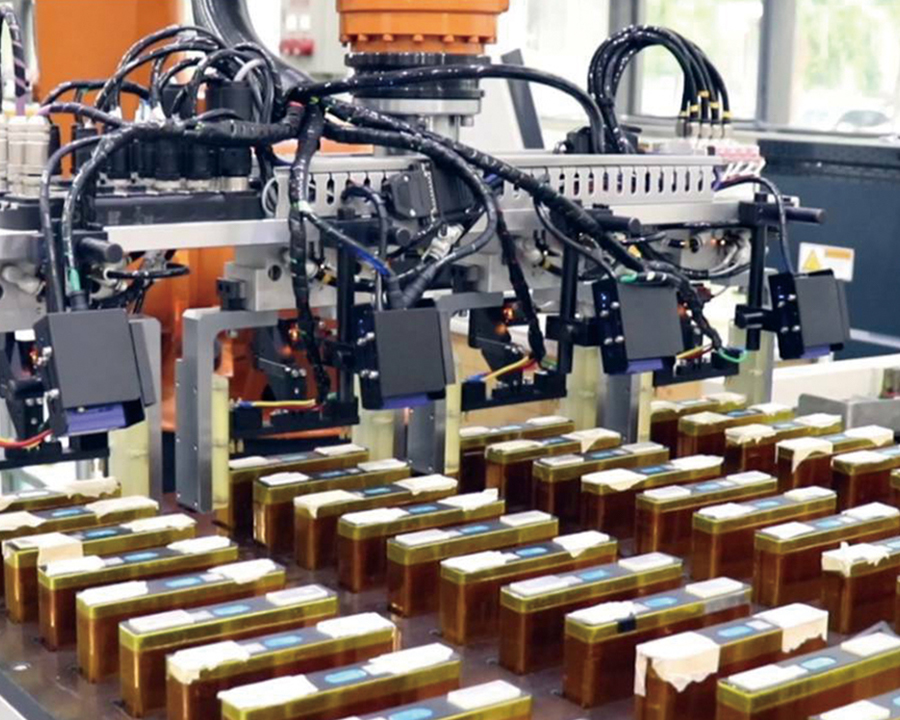

| Increased Automation and Robotics Integration | The trend towards lights-out manufacturing will see more robots integrated with wire harness machines for automated loading, unloading, and complex assembly tasks. |

| Industry 4.0 and Smart Manufacturing | Integration with the Industrial Internet of Things (IIoT) will allow machines to collect and transmit real-time data on performance, predictive maintenance needs, and production metrics, enabling smarter decision-making. |

| Advanced Vision Systems and AI for Quality Control | AI-powered vision systems will become even more sophisticated, capable of detecting minute defects and anomalies with greater accuracy, further enhancing quality assurance. |

| Miniaturization and Precision for Smaller Components | As electronic devices shrink, wire harness machines will need to handle increasingly smaller wires and connectors with even higher levels of precision. |

| Sustainability in Manufacturing | Future machines will focus on energy efficiency, reduced material waste, and the ability to process more environmentally friendly wire and insulation materials. |

| Customization and On-Demand Production | Advances in automation and software will enable quicker changeovers and more flexible production lines, supporting the growing demand for customized and on-demand wire harnesses. |

XI. Conclusion

Wire harness machines are the silent workhorses behind the functionality and reliability of countless electronic products that define our modern world. From the intricate wiring of an automobile to the delicate connections within a medical device, these machines ensure that power and data flow seamlessly and safely.

Their continuous evolution, driven by advancements in automation, AI, and connectivity, promises an even more efficient, precise, and sustainable future for manufacturing. As technology continues to advance, the role of wire harness machines will only grow in importance, solidifying their position as indispensable tools in the ongoing march of innovation.

English

English русский

русский عربى

عربى