Automatic spot welding machine: key technology to improve production efficiency and welding quality

As an efficient welding equipment, the automatic spot welding machine has become an indispensable part of modern manufacturing. Whether in automobile manufacturing, home appliance production, or in the field of electronic component assembly, spot welding technology is widely used. With the continuous acceleration of the industrialization process, the importance of automatic spot welding machines in production has become more and more significant.

Working principle and basic composition

The core principle of the automatic spot welding machine is to use the high temperature generated by the current to locally heat and melt the metal between the electrode and the workpiece, so that the two metal surfaces are combined to form a firm weld. In this process, the workpiece is accurately positioned and clamped by the automation system, and the current flows to the surface of the workpiece through the electrode, so that it is quickly heated to the required temperature. When the current is cut off, the metal cools and solidifies rapidly to complete the welding. Compared with traditional manual welding, the automatic spot welding machine can ensure the quality stability and consistency of the weld through efficient current control and mechanized welding process.

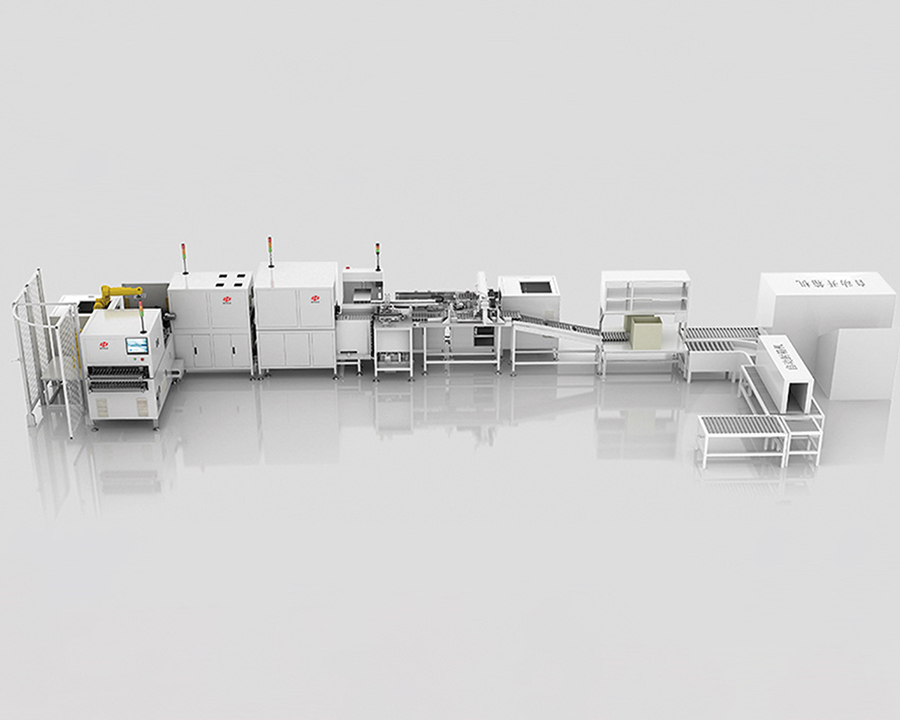

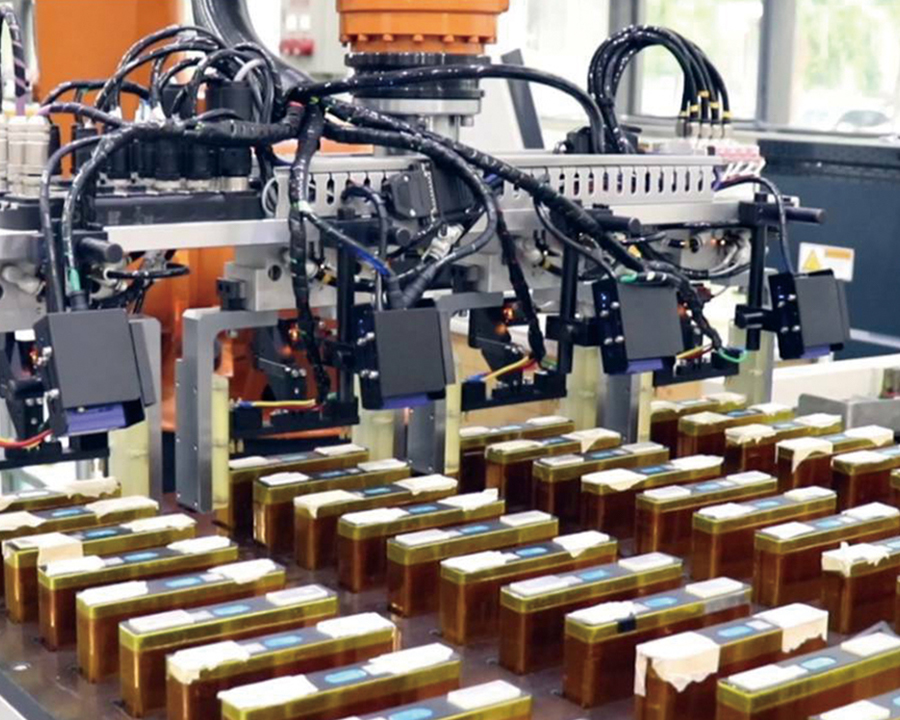

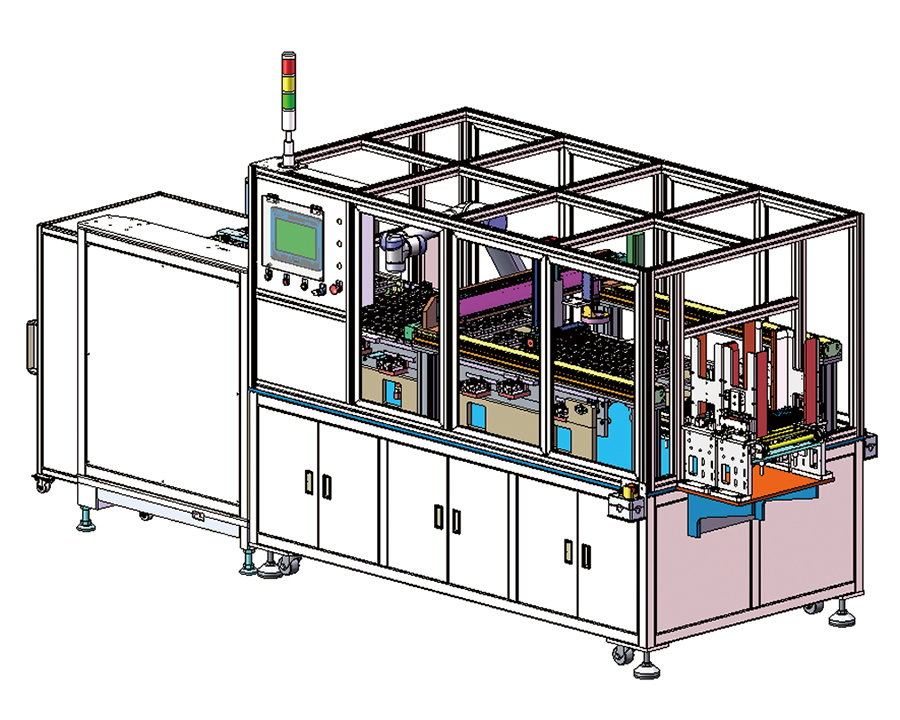

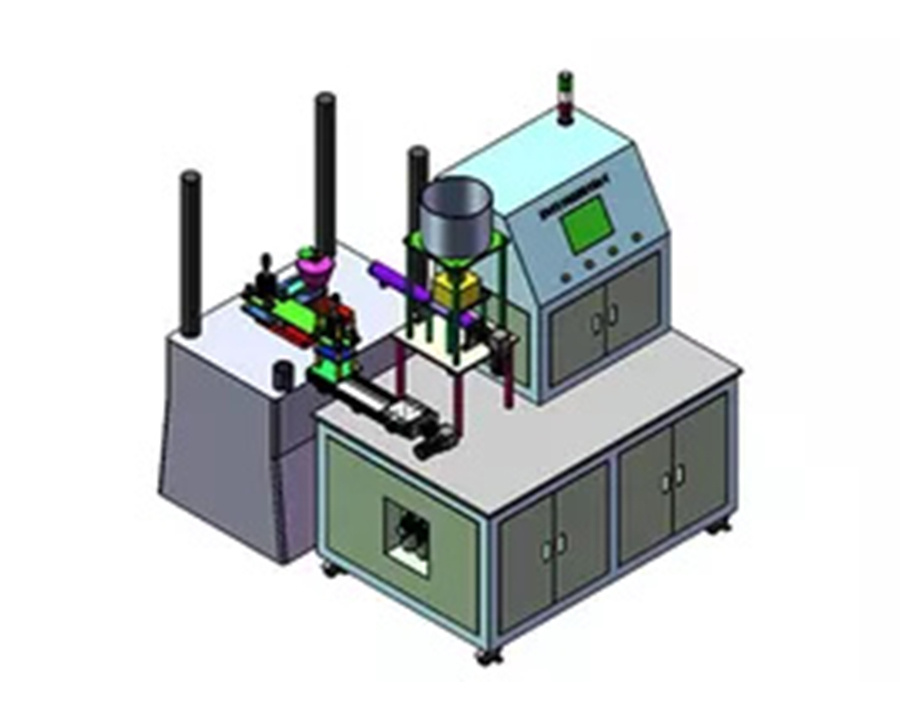

Automatic spot welding machines usually include key components such as welding power supply, welding electrode, control system and robotic arm. The electrode is used to transmit the current and concentrate it on the welding part of the workpiece; the welding power supply is responsible for providing stable current and voltage; the control system controls parameters such as welding time, welding pressure and current intensity through programming to ensure the accuracy and consistency of the welding process. The robotic arm automatically performs the welding task, thereby reducing manual intervention and improving work efficiency.

Application in different fields

The application of automatic spot welding machines has covered many fields, among which the automobile manufacturing industry is the most typical. In automobile production, body frames, doors, chassis and other parts need to be connected by high-precision spot welding technology. Automatic spot welding machines can provide high-speed and efficient welding, ensuring the quality and strength of each welding point, thereby improving the safety and durability of the entire vehicle.

The home appliance industry also relies on automatic spot welding machines to complete the welding of parts. For example, in home appliances such as rice cookers, air conditioners, and refrigerators, many metal parts are connected by spot welding technology. With automatic spot welding machines, the work efficiency on the production line is greatly improved, and the welding quality is more stable.

The electronics industry is also one of the important application areas of automatic spot welding machines. The welding of electronic components requires extremely high precision and stability, especially in key parts such as battery assembly and circuit board connection. The application of automatic spot welding machines not only improves production efficiency, but also ensures the quality of each solder joint, avoiding the defects and inconsistencies that may be caused by manual welding.

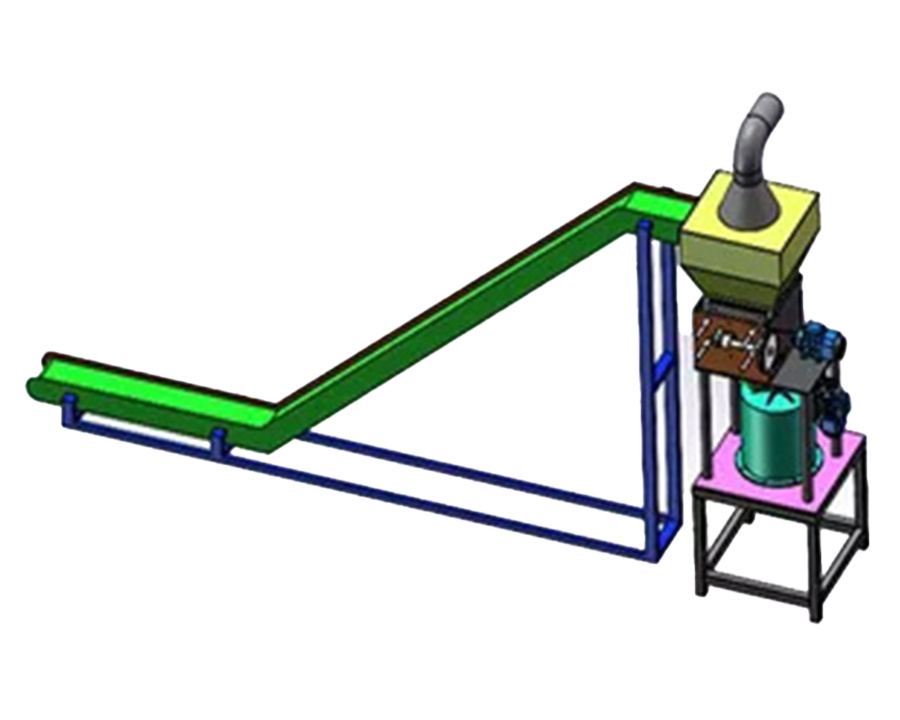

Automatic spot welding machines have also been widely used in metal product manufacturing, aerospace, electronic equipment and other fields.

Technical advantages of automatic spot welding machines

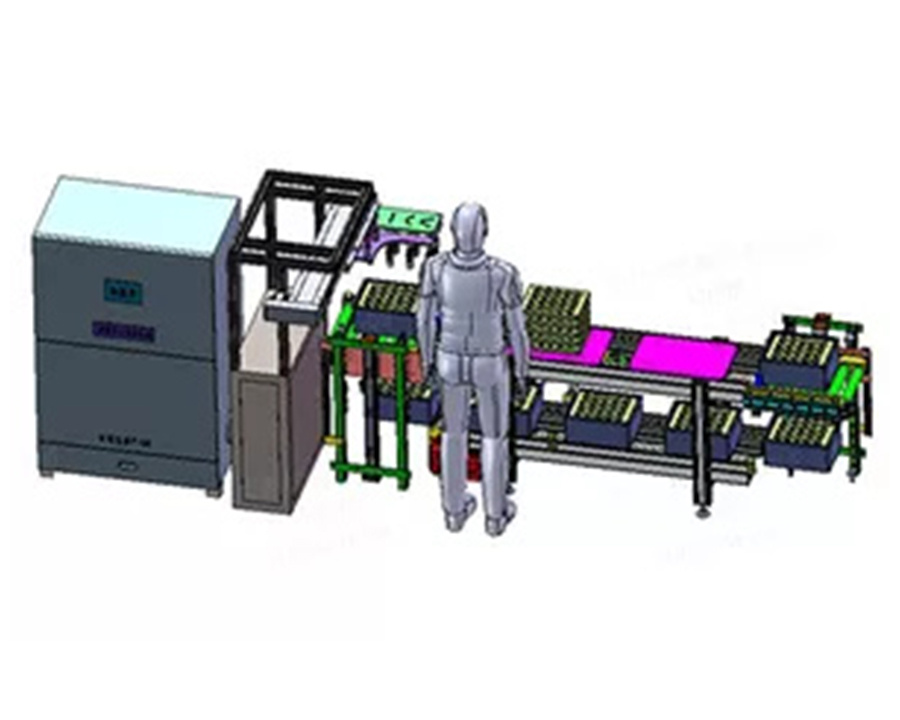

The technical advantages of automatic spot welding machines are mainly reflected in the following aspects. It is highly efficient and can complete welding tasks in a short time, significantly improving production efficiency. Traditional manual welding requires a lot of time and labor input, while automatic spot welding machines can complete welding at high speed and high precision to meet the needs of large-scale production.

Automatic spot welding machines can ensure the stability of welding quality. Under the precise control of the automation system, the quality of each solder joint can be kept consistent, avoiding the instability caused by manual operation. This is crucial for products that require high quality standards, especially in industries such as automobiles and aviation.

Automatic spot welding machines also have extremely high precision. Through precise current control and adjustment of welding time, a very detailed welding process can be achieved to meet the needs of different materials and workpiece shapes. For the welding of some precision parts, automatic spot welding machines can provide more stable and reliable results.

Automatic spot welding machines also have high energy-saving and environmental protection performance. Compared with traditional manual welding, automatic spot welding machines are more sophisticated in controlling current and time, avoiding overheating and energy waste, and reducing the emission of harmful gases.

Maintenance and care

Although automatic spot welding machines have many advantages, regular maintenance and care are essential to maintain their long-term and efficient operation. The electrode is an important part of the spot welding machine. After long-term use, it may be worn, so it is necessary to check and replace the electrode regularly to ensure the welding quality. Smoke and impurities in the welding process are easy to adhere to the surface of the equipment. Regular cleaning of the equipment is essential to extend its service life.

The stability of the power supply voltage also has an important impact on the welding quality. Too high or too low power supply voltage will lead to poor welding results, so it is necessary to regularly check the operating status of the power supply equipment to ensure its normal operation.

The maintenance of the lubrication system should not be ignored. The mechanical part needs to be regularly filled with lubricating oil to avoid affecting the equipment operation efficiency due to excessive friction.

As an important part of modern manufacturing technology, automatic spot welding machines have been widely used in many industries due to their advantages of high efficiency, precision and stability. With the continuous advancement of technology, automatic spot welding machines will play a greater role in future industrial production. For manufacturing companies, choosing an automatic spot welding machine with superior performance can not only improve production efficiency, but also ensure the stability of product quality, which is a key step to enhance corporate competitiveness.

English

English русский

русский عربى

عربى