Busbar assembly line: the core vein of power transmission

In modern power systems, busbar assembly lines play an extremely critical role. Like the arteries of the human body, they bear the heavy responsibility of gathering, distributing and transmitting electric energy. From power plants to substations, to various power facilities, busbar assembly lines are everywhere, and their efficient and stable operation is directly related to the reliability and safety of power supply.

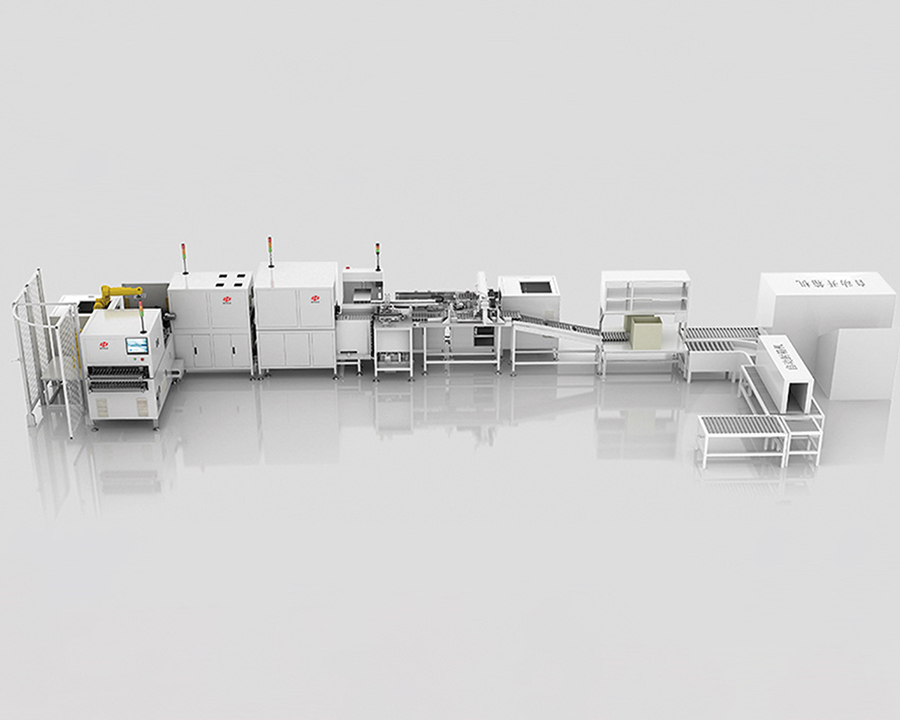

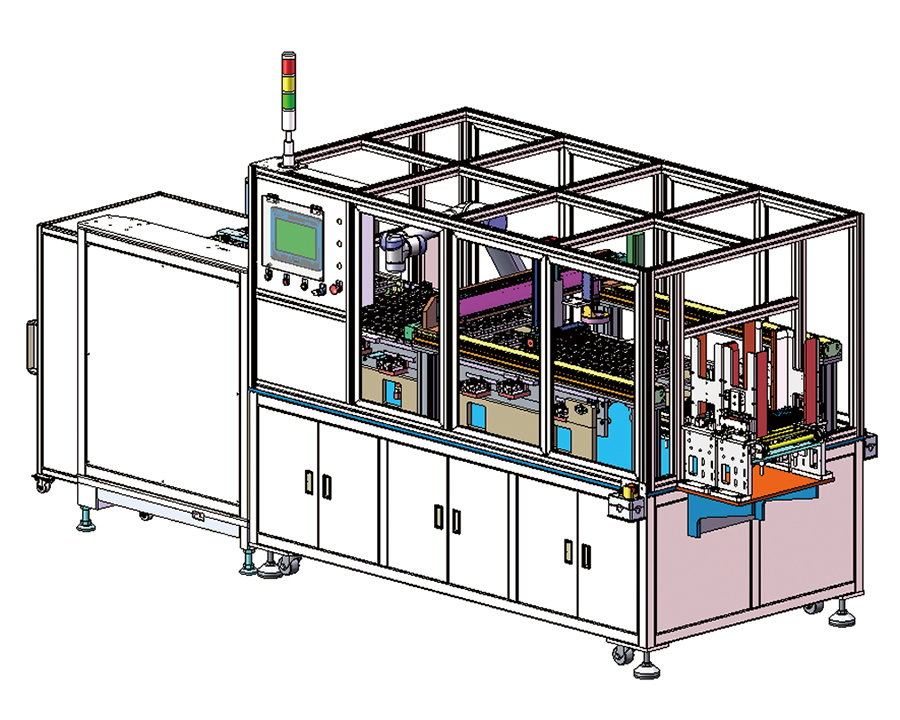

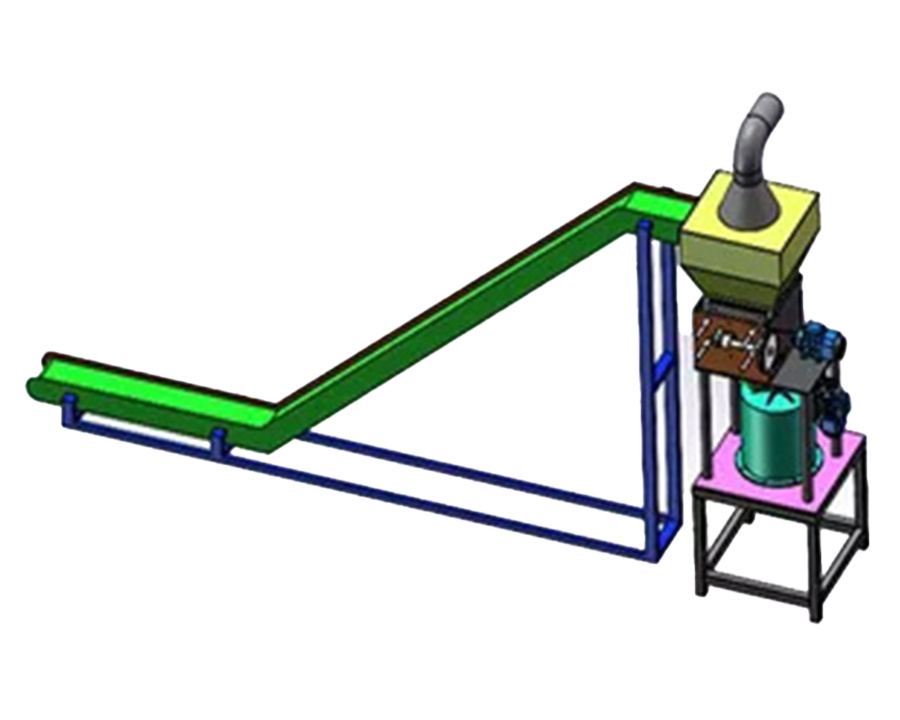

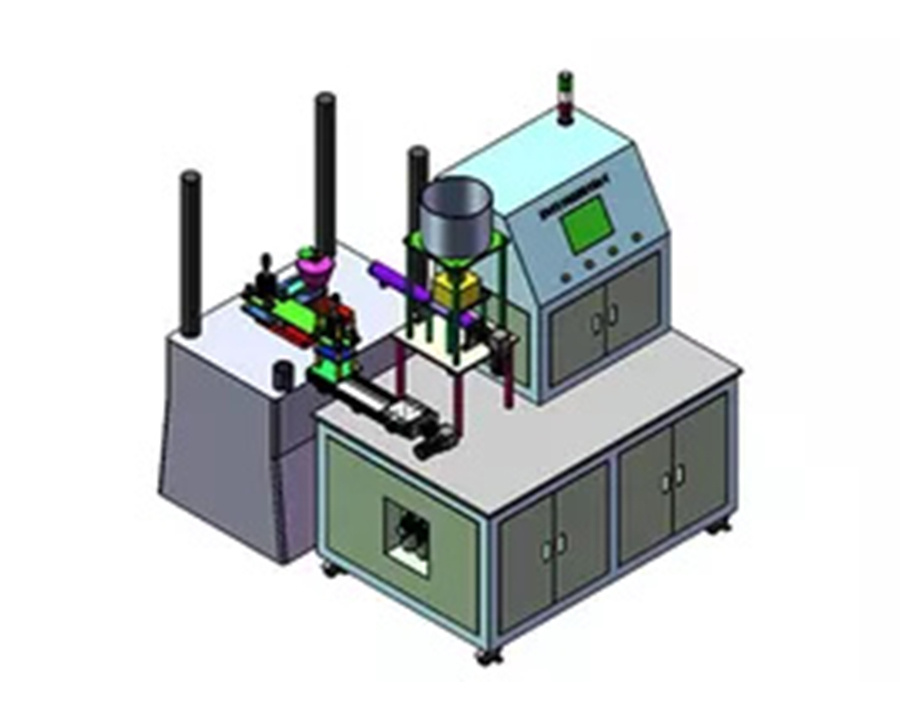

Composition of busbar assembly lines

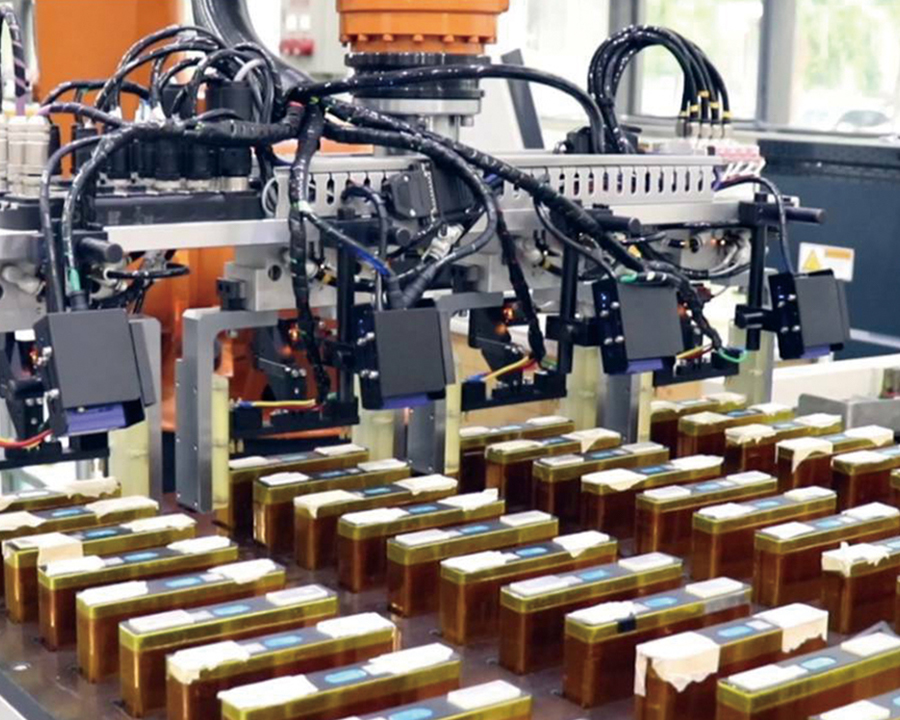

The busbar assembly line is mainly composed of busbar body, insulation support, connection parts and protective shell. As the core conductive component, the busbar body is mostly made of copper or aluminum with high conductivity. According to different current carrying requirements, it can be designed as a single or multiple conductors in parallel. For example, in large substations, in order to meet the huge power transmission needs, wide and thick copper busbars are often used to reduce resistance and reduce power loss. The insulation support plays the role of isolating the busbar from the outside world, ensuring that the current is transmitted along the predetermined path and preventing leakage accidents.

Common insulating materials include epoxy resin, ceramics, etc., which have excellent electrical insulation properties and mechanical strength. The connecting components are responsible for connecting each section of the busbar into a complete line to ensure the reliability and stability of the electrical connection. Bolting and welding are common connection methods. The protective shell can not only protect the busbar from the erosion of the external environment, but also provide certain mechanical protection to improve the overall safety of the assembly line.

Advantages of busbar assembly line

High current carrying capacity: The busbar assembly line is carefully designed to carry hundreds of amperes or even thousands of amperes of large current, meeting the power needs of various large industrial facilities, high-rise buildings, etc.

Low resistance and low loss: High-quality conductor materials and reasonable structural design make the resistance of the busbar assembly line extremely low, thereby effectively reducing the loss of electricity during transmission. Compared with traditional cable transmission, busbar assembly lines can significantly improve energy utilization efficiency and reduce operating costs. In some large factories, the use of busbar assembly lines for power transmission can save a lot of electricity expenses every year.

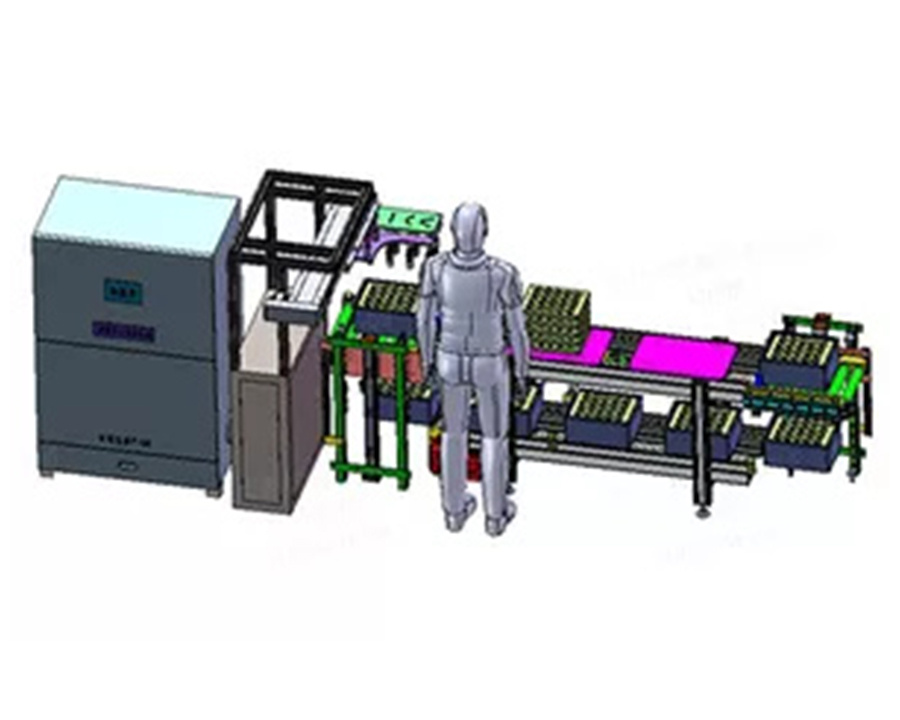

Easy to install and maintain: The busbar assembly line usually adopts a modular design. After the components are prefabricated in the factory, they are transported to the site for rapid assembly, which greatly shortens the installation cycle. Moreover, its structure is relatively simple, which is convenient for daily inspection, maintenance and troubleshooting. When a section of the busbar has a problem, the faulty parts can be quickly disassembled and replaced to reduce power outage time and ensure the continuity of power supply.

Application scenarios of busbar assembly line

Industrial field: In large industrial enterprises such as steel, chemical, and automobile manufacturing, busbar assembly lines are widely used in the power distribution system of workshops. These enterprises have many production equipment and large and complex power loads. Busbar assembly lines can reliably provide stable power support for various large machine tools, production lines and other equipment to ensure the smooth progress of the production process.

Commercial buildings: Commercial places such as large shopping malls, shopping centers, and hotels have extremely high requirements for the stability and reliability of power supply due to the large number of internal electrical equipment, such as lighting systems, ventilation and air-conditioning systems, and elevator systems. With its excellent performance, busbar assembly lines have become the preferred solution for power transmission in these commercial buildings to ensure the normal development of commercial operations.

Power substation: As a key hub of the power system, substations require efficient and reliable power transmission and distribution equipment. The busbar assembly line undertakes the important task of connecting various voltage equipment in the substation, realizing the collection and distribution of electric energy, and ensuring the safe and stable operation of the power system.

With the continuous advancement of science and technology, the busbar assembly line is also continuing to innovate and develop. In the future, materials with higher conductivity, more advanced insulation technology, and intelligent monitoring and management systems will be applied to the busbar assembly line, further improving its performance and reliability, and injecting new vitality into the development of the power industry.

English

English русский

русский عربى

عربى