Automatic spot welding machine: a precision welding tool for modern manufacturing industry

I. Introduction

In the grand landscape of modern manufacturing industry, welding technology is like an indispensable cornerstone, supporting the development of many industries. From the huge body structure of automobile manufacturing to the connection of tiny parts in electronic equipment, the quality and efficiency of welding are directly related to the performance, reliability and economic efficiency of the product. As a shining star in the field of welding technology, the automatic spot welding machine is leading the transformation and innovation of welding technology with its excellent automation, high precision and high efficiency, and profoundly affecting and shaping the pattern of modern manufacturing industry.

The emergence of automatic spot welding machine can be regarded as a major leap in the field of welding. It perfectly integrates advanced automation control technology, precise mechanical design and efficient welding power supply, completely changing the high dependence of traditional welding methods on manual skills, and realizing precise control and stable operation of the welding process. In the scenario of large-scale production, the automatic spot welding machine can complete a large number of spot welding tasks with amazing speed and consistency, which not only greatly improves production efficiency, but also significantly improves the stability of product quality, and wins key advantages for enterprises in the fierce market competition.

2. Working Principle

2.1 Principle of Resistance Spot Welding

Resistance spot welding is one of the most commonly used working modes of automatic spot welding machines. Its principle is based on Joule's law, that is, when current passes through a conductor, heat is generated, and the amount of heat is proportional to the square of the current, the resistance of the conductor, and the power-on time. During the resistance spot welding process, the electrode of the automatic spot welding machine clamps the workpiece tightly so that the current can pass through the contact point of the workpiece. Since the resistance at the contact point of the workpiece is relatively large, a large amount of heat will be generated here when the current passes through, instantly heating the metal at the contact point to a molten state, forming a molten core. Under the pressure of the electrode, after the molten core cools and solidifies, the two workpieces are firmly connected together.

In order to understand the principle of resistance spot welding more deeply, we can divide its process into the following stages: First, there is the pre-pressing stage, in which the electrode drops rapidly and applies a certain pressure to make the workpieces in close contact to ensure that the current can pass smoothly. Then enter the welding stage, in which a strong current passes through the contact point of the workpiece in a short time, generating high temperature to melt the metal and form a molten core. Then comes the maintenance stage, in which the electrode maintains pressure to allow the molten core to slowly cool and solidify under pressure to ensure the strength of the weld. Finally, there is the resting stage, when the electrode rises and a spot welding process is completed.

In this process, welding current, welding time and electrode pressure are three key parameters that affect the quality of resistance spot welding. The size of the welding current directly determines the amount of heat generated. Excessive current may cause problems such as weld spatter and burn-through of the workpiece, while too small current will make the weld insufficient in strength. The length of the welding time is also crucial. Too short welding time cannot fully melt the metal to form a molten core of sufficient strength. Too long welding time may cause the weld to overheat and coarse grains, affecting the performance of the weld. The electrode pressure plays a role in ensuring close contact between the workpiece, promoting heat transfer and preventing weld spatter. Excessive or too small pressure will have an adverse effect on the quality of the weld. Therefore, in the actual welding process, it is necessary to accurately adjust these three parameters according to the material, thickness and welding requirements of the workpiece to obtain the best welding effect.

2.2 Principle of laser spot welding

As an emerging welding technology, laser spot welding has also been widely used in automatic spot welding machines. The principle is to use a high-energy-density laser beam to irradiate the surface of the workpiece, so that the irradiated material quickly absorbs the laser energy and converts it into heat energy, so that the surface temperature of the material rises sharply, reaches the melting point or even the boiling point, and the material melts or vaporizes instantly. After the laser beam stops irradiating, the molten material quickly cools and solidifies, thereby realizing the welding of the workpiece.

The laser spot welding process is highly accurate and controllable. Because the energy of the laser beam is highly concentrated, it can generate high temperature in a very small area, so it can achieve high-precision welding of tiny parts, and the thermal impact on the surrounding materials is minimal. The speed of laser spot welding is very fast, and a large number of spot welding tasks can be completed in a short time, greatly improving production efficiency.

Compared with resistance spot welding, laser spot welding has some unique advantages. First, laser spot welding can weld various types of materials, including some refractory metals and dissimilar materials, while resistance spot welding may encounter difficulties when welding certain materials. Secondly, the weld quality of laser spot welding is higher, the surface of the weld is smooth, and there is no obvious deformation and defects, which can meet some application scenarios with extremely high requirements for welding quality, such as welding of electronic chips and manufacturing of aerospace parts. However, laser spot welding also has some limitations, such as high equipment cost and more stringent requirements for the working environment.

2.3 Brief description of other working methods

In addition to resistance spot welding and laser spot welding, automatic spot welding machines have some other working methods, such as capacitor energy storage spot welding, projection welding, etc., which also play an important role in different application scenarios.

Capacitor energy storage spot welding uses the electrical energy stored in the capacitor to release it instantly to weld the workpiece. This welding method is characterized by extremely short welding time, usually completing the welding process in a few milliseconds or even shorter, which can effectively reduce the heat-affected zone and is suitable for welding heat-sensitive materials, such as electronic components. In the capacitor energy storage spot welding process, the capacitor is first charged to a certain voltage through the charging circuit to store enough electrical energy. When welding, the control circuit triggers the discharge switch, so that the electrical energy in the capacitor is instantly released to the workpiece through the electrode, generating high temperature to achieve welding. Due to the short welding time, capacitor energy storage spot welding can minimize the thermal impact on surrounding materials while ensuring the welding quality. It is particularly suitable for welding some temperature-sensitive materials, such as semiconductor components, precision electronic circuit boards, etc.

Projection welding is to pre-process a convex point on a workpiece, then stack the two workpieces together, apply pressure and current through the electrode, so that the metal at the convex point melts and connects together. Projection welding is mainly used to weld some thin plate materials, which can improve welding efficiency and welding quality, reduce the number of welds, and reduce welding costs. In the projection welding process, factors such as the shape, size, and distribution position of the convex point will affect the welding quality. Reasonable design of the parameters of the convex point can concentrate the current at the convex point and improve the reliability and consistency of welding. Projection welding is often used for thin plate welding in automobile manufacturing, such as welding of body panels and welding of automobile seat frames, which can effectively improve production efficiency and reduce production costs.

These different working modes have their own characteristics and scope of application. In practical applications, it is necessary to select the appropriate automatic spot welding machine working mode according to factors such as the material, shape, size, and welding requirements of the workpiece to ensure welding quality and production efficiency.

3. Core structure and components

3.1 Welding power supply system

As the "heart" of the automatic spot welding machine, the welding power supply system undertakes the important task of providing stable and reliable energy for the welding process. The quality of its performance directly determines the quality of welding and the overall operating stability of the equipment. According to different working principles and application requirements, welding power supply systems are mainly divided into industrial frequency AC power supply, medium frequency inverter power supply and capacitor energy storage power supply.

Industrial frequency AC power supply is a more traditional welding power supply. It directly reduces the voltage of the mains (usually 50Hz or 60Hz AC) through a transformer, and then outputs the current and voltage suitable for welding. This power supply structure is relatively simple and low cost, but because its output current waveform is a sine wave, it will produce large current fluctuations during the welding process, resulting in unstable welding quality and a greater impact on the power grid.

Medium frequency inverter power supply is an advanced welding power supply that has developed rapidly in recent years. It first rectifies the mains and converts it into DC power, then uses an inverter circuit to invert the DC power into AC power with a higher frequency (usually 1-20kHz), and finally reduces the voltage of the transformer to output the current and voltage required for welding. Due to the high operating frequency of the medium frequency inverter power supply, it can make the welding current more stable and the heat input control more precise, thereby greatly improving the welding quality. At the same time, its power factor is high, the pollution to the power grid is small, and the energy saving effect is significant. In some fields with high requirements for welding quality, such as automobile manufacturing, aerospace, etc., medium-frequency inverter power supply has gradually become the mainstream welding power supply choice.

Regardless of the type of welding power supply system used, its key technical indicators include output current stability, current adjustment range, dynamic response speed, etc. The stability of the output current is the key to ensuring the consistency of welding quality. The stable current can ensure that the heat generated during each welding is uniform, thereby forming a weld with stable quality. The current adjustment range determines that the power supply can adapt to the welding needs of workpieces of different materials and thicknesses. The wider the adjustment range, the stronger the versatility of the equipment. The dynamic response speed reflects the power supply's ability to quickly adjust the current changes during the welding process. During the welding process, when the workpiece material is uneven and the contact resistance changes, the fast dynamic response can adjust the current in time to ensure the smooth progress of the welding process.

3.2 Control system

The control system is like the "brain" of the automatic spot welding machine, responsible for precise control and monitoring of the entire welding process. It integrates advanced sensor technology, programmable logic controller (PLC) and intelligent control algorithm to achieve accurate setting of welding parameters, real-time adjustment and automatic operation of welding process.

In the control system of automatic spot welding machine, sensors play a vital role. For example, the current sensor is used to monitor the size of welding current in real time, convert the current signal into an electrical signal and feed it back to the control system so that the control system can adjust the current according to the set welding parameters. The voltage sensor is used to monitor the output voltage of the welding power supply to ensure that the voltage is stable within the appropriate range. The pressure sensor is installed on the electrode to measure the pressure applied by the electrode to the workpiece to ensure that the pressure meets the welding process requirements. In addition, there are temperature sensors, displacement sensors, etc., which monitor various physical quantities in the welding process from different angles in real time and provide comprehensive and accurate data support for the control system.

The programmable logic controller (PLC) is the core operation and control unit of the control system. It accurately controls the welding power supply system, electrode drive system, etc. according to the preset welding program and the data fed back by the sensor. By writing different PLC programs, various complex welding process requirements can be realized, such as multi-stage welding current control, accurate setting of welding time, dynamic adjustment of electrode pressure, etc. At the same time, PLC also has powerful logic processing capabilities, which can analyze and judge various signals in the welding process and realize automated welding process control, such as automatic loading, welding, unloading, etc.

The application of intelligent control algorithms further improves the performance of the automatic spot welding machine control system. For example, the use of fuzzy control algorithms, neural network control algorithms, etc., can enable the control system to automatically adjust the welding parameters according to the real-time situation in the welding process to achieve adaptive control. In the actual welding process, due to the material, thickness, surface state and other factors of the workpiece, there may be certain differences, and the traditional fixed parameter control method is difficult to ensure the consistency of welding quality. The intelligent control algorithm can analyze the state of the welding process in real time according to the data fed back by the sensor, and automatically adjust the welding current, time, pressure and other parameters, so that the welding process is always in the best state, thereby greatly improving the stability and reliability of the welding quality.

3.3 Electrode and pressure system

The electrode and pressure system are the key executive components of the automatic spot welding machine that directly acts on the workpiece to realize the welding process. As the conducting medium of the welding current and the carrier of the applied pressure, the performance and quality of the electrode have a vital impact on the welding effect.

Electrodes are usually made of materials with high electrical conductivity, high thermal conductivity and good wear resistance, such as copper alloy, tungsten copper alloy, etc. Different welding processes and workpiece materials have different requirements for the shape, size and material of electrodes. For example, in resistance spot welding, commonly used electrode shapes include cylindrical flat head type, conical type, spherical type, etc. Cylindrical flat head type electrodes are suitable for general thin plate welding, which can provide a larger contact area and ensure the uniform distribution of welding current; conical type electrodes are suitable for welding thicker workpieces, which can make the current more concentrated and improve welding efficiency; spherical type electrodes are often used for welding some workpieces with high requirements for the surface quality of the weld, such as welding of electronic components, which can reduce the indentation on the surface of the weld.

The electrode pressure system is responsible for providing stable and adjustable pressure for the electrode, so that the workpiece can be in close contact during the welding process, ensuring the smooth passage of welding current and promoting the formation of welds. The pressure system is generally composed of a drive device such as a cylinder, a hydraulic cylinder or an electric push rod, and a pressure regulating device. The pressure system driven by the cylinder has a simple structure, fast response speed, and low cost, and is suitable for general welding occasions; the pressure system driven by the hydraulic cylinder can provide a large pressure and a wide pressure adjustment range, which is suitable for welding thicker workpieces or occasions with high pressure accuracy requirements; the pressure system driven by the electric push rod has the advantages of high control accuracy and accurate position control, and is widely used in some automatic spot welding machines with a high degree of automation.

The pressure regulating device is an important part of the pressure system. It can accurately adjust the pressure applied by the electrode to the workpiece according to the requirements of the welding process. Common pressure regulation methods include mechanical pressure regulation, pneumatic pressure regulation and hydraulic pressure regulation. Mechanical pressure regulation changes the compression of the spring by adjusting the position of the screw to achieve pressure regulation. This method has a simple structure, but the regulation accuracy is relatively low; pneumatic pressure regulation and hydraulic pressure regulation adjust the electrode pressure by adjusting the pressure of the gas or liquid. The regulation accuracy is high, the response speed is fast, and remote control and automatic regulation can be achieved through the control system.

In the actual welding process, electrode wear is an inevitable problem. With the increase in the number of welding times, the electrode surface will gradually wear, resulting in changes in the shape and size of the electrode, which affects the welding quality. Therefore, it is necessary to regularly inspect and maintain the electrodes and replace the severely worn electrodes in time. At the same time, some advanced automatic spot welding machines are also equipped with electrode wear monitoring systems, which can monitor the wear of the electrodes in real time and automatically adjust the welding parameters according to the degree of wear to ensure the stability of welding quality.

3.4 Automatic conveying and positioning mechanism

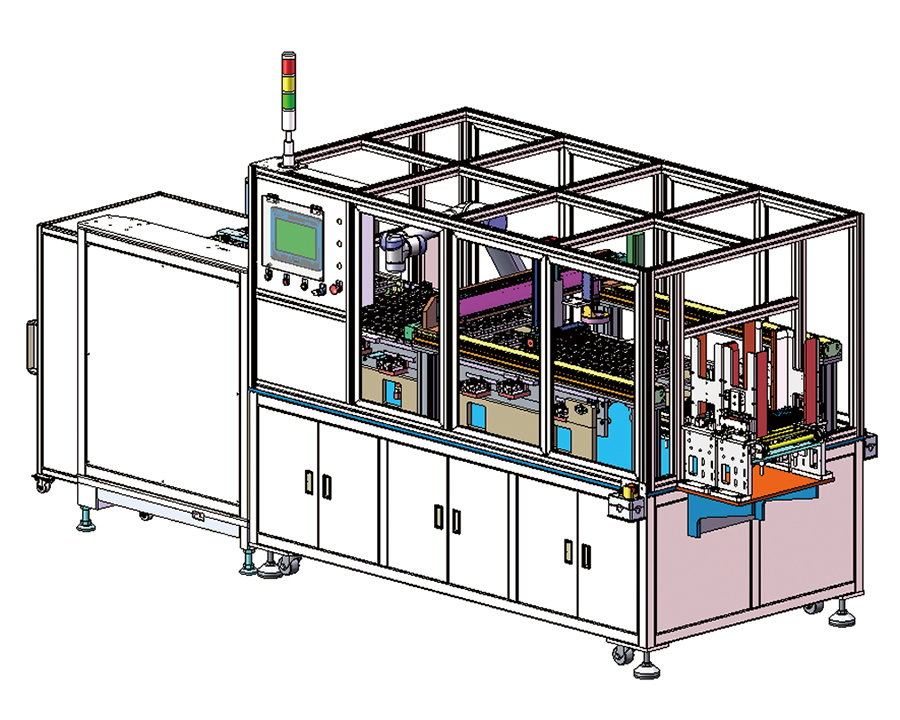

In the context of modern automated production, the automatic conveying and positioning mechanism of automatic spot welding machines has become a key factor in improving production efficiency and welding accuracy. These mechanisms are like precision "porters" and "Positioning device" can accurately transport the workpiece to the welding position and ensure that the workpiece always maintains a stable posture during the welding process.

Automated conveying mechanism is usually composed of transmission parts such as conveyor belt, chain, roller, and drive devices such as motor and reducer. Conveyor belt is one of the most common conveying methods. It has the advantages of smooth conveying, strong load-bearing capacity, and adjustable conveying speed. According to different application scenarios and workpiece characteristics, the material of the conveyor belt can be rubber, plastic, metal, etc. For example, in the electronic and electrical industry, since the workpiece is usually light and has high requirements for surface quality, anti-static rubber conveyor belts are often used to prevent static electricity from damaging electronic components; while in industries such as automobile manufacturing, due to the heavy workpiece, metal conveyor belts or chain conveying methods may be used to ensure that they can withstand large loads.

As the power source of the automated conveying mechanism, the motor converts the high-speed rotation of the motor into a low-speed and high-torque output suitable for the conveying speed through the reducer to drive the transmission parts such as the conveyor belt or chain to run. In order to achieve precise conveying control, the motor usually uses a variable frequency speed regulating motor or a servo motor. The variable frequency speed regulating motor can change the motor speed by adjusting the power supply frequency, thereby realizing stepless adjustment of the conveying speed; the servo motor has higher control accuracy and response speed, and can realize precise position control and speed control. In some occasions with extremely high conveying accuracy requirements, such as the welding of semiconductor chips, the conveying mechanism driven by the servo motor has been widely used.

The function of the positioning mechanism is to accurately position the workpiece under the welding electrode after it is conveyed to the welding position to ensure the accuracy of the welding position. Common positioning methods include mechanical positioning, pneumatic positioning and visual positioning. Mechanical positioning uses mechanical structures such as positioning pins and positioning blocks to position the workpiece. This method has a simple structure and high positioning accuracy, but it has strict requirements on the shape and size accuracy of the workpiece, and the positioning device needs to be readjusted when replacing workpieces of different specifications. Pneumatic positioning uses cylinders to drive positioning elements to position the workpiece. It has the advantages of fast positioning speed and easy adjustment, and is suitable for some occasions with high positioning speed requirements. Visual positioning is an advanced positioning technology that has developed rapidly in recent years. It collects image information of the workpiece through a camera, uses image processing algorithms to identify and analyze the position and posture of the workpiece, and then drives the positioning mechanism through the control system to accurately adjust the workpiece. Visual positioning has the advantages of high positioning accuracy and strong adaptability. It can quickly and accurately position workpieces of various shapes and sizes. It is particularly suitable for some complex-shaped workpieces or welding occasions with extremely high positioning accuracy requirements.

In order to ensure the efficient operation of the automated conveying and positioning mechanism, it is also necessary to accurately control and monitor it. The control system works in conjunction with the welding power supply system, electrode pressure system, etc. to achieve automated control of the entire welding process. For example, after the workpiece is transported to the welding position, the control system triggers the positioning mechanism to position the workpiece. After the positioning is completed, the control system controls the electrode to descend and apply pressure, and starts the welding power supply for welding. After the welding is completed, the control system controls the electrode to rise, and then drives the automated conveying mechanism to transport the welded workpiece out, and transports the next workpiece to be welded to the welding position, and so on, to achieve efficient automated welding production.

IV. Performance advantages

4.1 High-precision welding

In the manufacturing industry, for many products, welding accuracy is directly related to the performance and quality of the product. With its advanced technology and precise structure, the automatic spot welding machine has demonstrated excellent performance in high-precision welding.

Its high precision is first due to the precise control system. The automatic spot welding machine is equipped with advanced sensors that can monitor key parameters such as current, voltage, pressure, and temperature during the welding process in real time. These sensors quickly feed back the collected data to the control system, and the control system accurately adjusts the welding process through intelligent control algorithms according to the preset welding process parameters. For example, during the welding process, if the current sensor detects a slight fluctuation in the current, the control system will immediately adjust the output of the welding power supply to restore the current to the set value, thereby ensuring the stability and consistency of the welding process and ensuring the quality and dimensional accuracy of the weld.

The precise design of the electrode and pressure system also provides a strong guarantee for high-precision welding. The electrode is made of high-quality materials and precise processing technology, and its shape and dimensional accuracy can meet the requirements of high-precision welding. At the same time, the pressure system can accurately control the pressure applied by the electrode to the workpiece, and the stability and accuracy of the pressure directly affect the quality of the weld formation. When welding some tiny parts with extremely high precision requirements, such as pin welding in electronic chips, the automatic spot welding machine can accurately control the electrode pressure to ensure good contact between the pin and the substrate during welding, thereby forming high-quality welds and avoiding problems such as cold welding and short circuits.

The high-precision positioning capability of the automated conveying and positioning mechanism is one of the key factors in achieving high-precision welding. These mechanisms can accurately convey the workpiece to the welding position and maintain the stable posture of the workpiece during the welding process. For example, in the manufacturing of automotive parts, for the welding of some complex-shaped parts, the automated conveying and positioning mechanism can accurately position the parts under the welding electrode according to the pre-set program, and the positioning accuracy can reach ±0.01mm or even higher, ensuring the accuracy of the welding position, thereby ensuring the consistency and reliability of the welding quality.

4.2 High-efficiency production

The high-efficiency production characteristics of the automatic spot welding machine are an important reason for its widespread application in modern manufacturing. Traditional manual spot welding relies on the experience and proficiency of the welder, is slow and prone to fatigue, resulting in unstable production efficiency. The automatic spot welding machine can greatly improve the welding speed and production efficiency through automated process design and fast response mechanism.

From the perspective of the welding cycle, the welding process of the automatic spot welding machine can be highly automated and fast. Taking the common spot welding of automobile bodies as an example, the automatic spot welding machine can complete a spot welding operation in just a few seconds and can work continuously. In contrast, manual spot welding not only takes a long time for a single welding point, but also requires welders to move frequently between different welding points, which greatly reduces production efficiency. The automatic spot welding machine can quickly transport the workpiece to the welding position through the automated conveying and positioning mechanism. After the welding is completed, the finished product can be quickly removed and sent to the next workpiece to be welded. The whole process is done in one go, with almost no pause time, which greatly shortens the production cycle.

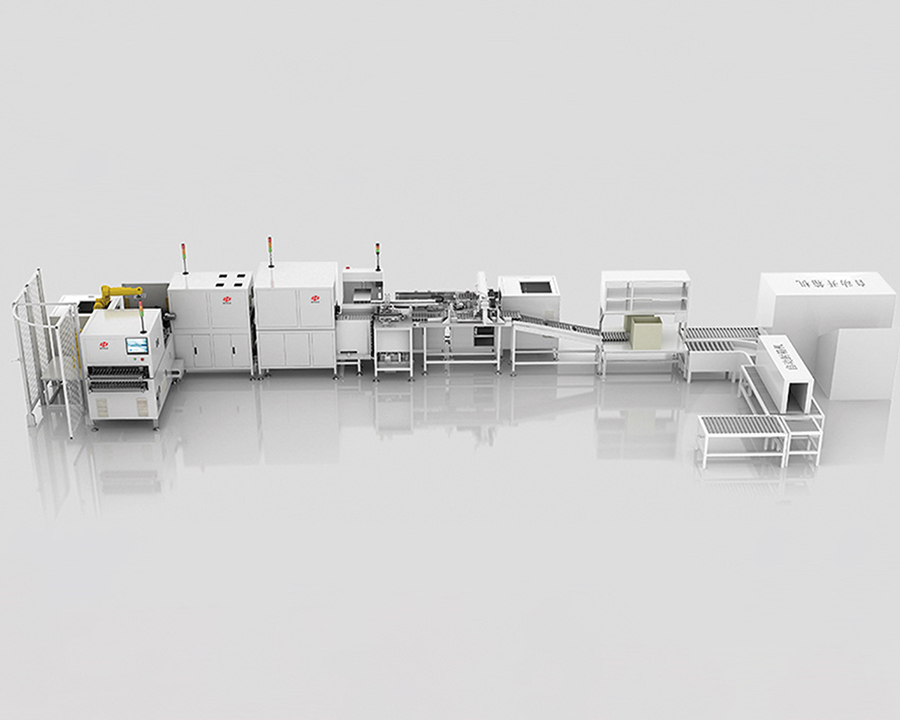

The automatic spot welding machine can realize simultaneous welding of multiple stations, further improving production efficiency. Some large-scale automatic spot welding production lines are equipped with multiple welding stations, each of which can weld different parts of the workpiece at the same time. This parallel operation method can complete more welding tasks in the same time. In the production of battery modules, the multi-station automatic spot welding machine can spot weld multiple connection points of the battery cell at the same time. Compared with the method of welding a single welding point in sequence, the production efficiency can be increased several times.

The automatic spot welding machine can also seamlessly connect with other automated equipment and production lines to achieve full automation of the production process. For example, in the manufacturing of electronic products, automatic spot welding machines can form a complete automated production line with automatic feeders, testing equipment, packaging equipment, etc. From the transportation of raw materials, welding processing to the testing and packaging of finished products, the entire process does not require human intervention and can run 24 hours a day, greatly improving production efficiency and capacity.

4.3 Stable welding quality

Stable welding quality is one of the core advantages of automatic spot welding machines and a key guarantee for the pursuit of product consistency and reliability in the manufacturing industry. During manual spot welding, welding quality is easily affected by a variety of human factors such as welder mood, skill level, and working status, resulting in uneven quality of welds. The automatic spot welding machine can ensure highly consistent quality of each welding through precise parameter control and stable working performance.

The welding power supply system of the automatic spot welding machine can provide stable current output, which is the basis for ensuring stable welding quality. Whether it is industrial frequency AC power supply, medium frequency inverter power supply or capacitor energy storage power supply, they have been carefully designed and optimized to maintain current stability under different welding conditions. Stable current means that the heat generated during each welding is basically the same, so that the size and shape of the weld nugget remain consistent, ensuring the strength and reliability of the weld.

The control system plays an important role in maintaining stable welding quality. It can monitor and adjust various parameters in the welding process in real time, and automatically correct them immediately once the parameters deviate from the preset values. For example, when it is detected that the surface state of the workpiece changes and the contact resistance increases, the control system will automatically increase the welding current or extend the welding time to ensure the normal progress of the welding process and the quality of the weld.

The stability of the electrode and pressure system is also an important factor in ensuring welding quality. The wear resistance and good electrical and thermal conductivity of the electrode can maintain stable performance during long-term welding and reduce the degradation of welding quality caused by electrode wear. The pressure system can accurately control the pressure of the electrode on the workpiece to ensure that the contact tightness between the workpieces is consistent during each welding, thereby ensuring the quality of the weld. Regular maintenance and replacement of electrodes, as well as calibration and debugging of the pressure system, can further improve the stability and reliability of welding quality.

4.4 Reduce labor intensity and labor costs

In traditional manual welding operations, welders need to maintain a fixed posture for a long time and hold the welding gun for repeated operations, which is extremely labor-intensive. Long-term work can easily lead to welder fatigue and increase the risk of industrial accidents. The emergence of automatic spot welding machines has greatly improved this situation. The automated operation process of the automatic spot welding machine allows workers to monitor the equipment, set parameters, and load and unload materials without directly participating in the welding process, which greatly reduces the labor intensity. Workers can be freed from heavy physical labor and devote more energy to more technical work such as equipment maintenance and quality inspection.

From the perspective of labor costs, automatic spot welding machines can significantly reduce the labor costs of enterprises. A production line equipped with automatic spot welding machines requires far fewer operators than traditional manual welding production lines. Taking automobile manufacturing as an example, after adopting the automatic spot welding production line, the welding tasks that originally required dozens of welders to complete now only require a few skilled workers to manage and monitor the equipment. Moreover, the operation of the automatic spot welding machine is relatively simple, and the skill requirements for workers are relatively low. Enterprises do not need to spend a lot of time and money on long-term professional training for workers, which further reduces labor cost expenditure. In addition, the efficient production capacity of the automatic spot welding machine enables enterprises to complete more production tasks in the same time, improve production efficiency, and reduce the labor cost allocated to a single product, thereby improving the economic benefits and market competitiveness of the enterprise.

V. Application Fields

5.1 Automobile Manufacturing Industry

The automobile manufacturing industry is one of the most widely and deeply applied fields of automatic spot welding machines. The automobile body is made of a large number of metal plates connected by welding, with a large number of welding points, and the requirements for welding quality and production efficiency are extremely high. The automatic spot welding machine has become a key equipment for automobile body manufacturing with its high precision, high efficiency and stable welding quality.

In the process of stamping welding of automobile body, the automatic spot welding machine can quickly and accurately weld stamping parts of different shapes and sizes together to form the skeleton structure of the body. For example, in the welding of car doors, roofs, floor panels and other parts, the automatic spot welding machine can accurately place the stamping parts at the welding position through the automated conveying and positioning mechanism, and then use the multi-station simultaneous welding technology to complete the welding of a large number of welds in a short time, greatly improving production efficiency. Moreover, the automatic spot welding machine can accurately control the welding parameters to ensure the consistency of the quality of each weld, ensuring the strength and safety of the body structure.

In the welding of automobile chassis, the automatic spot welding machine also plays an important role. Chassis components usually bear large loads and have more stringent requirements on welding quality. The automatic spot welding machine can provide stable high-current output and achieve high-quality welding of thicker plates by adopting advanced welding power supply systems such as medium-frequency inverter power supply or capacitor energy storage power supply. At the same time, its high-precision electrode and pressure system can ensure that the size and shape of the weld nugget of the weld meet the design requirements, ensuring the connection strength and reliability of the chassis components.

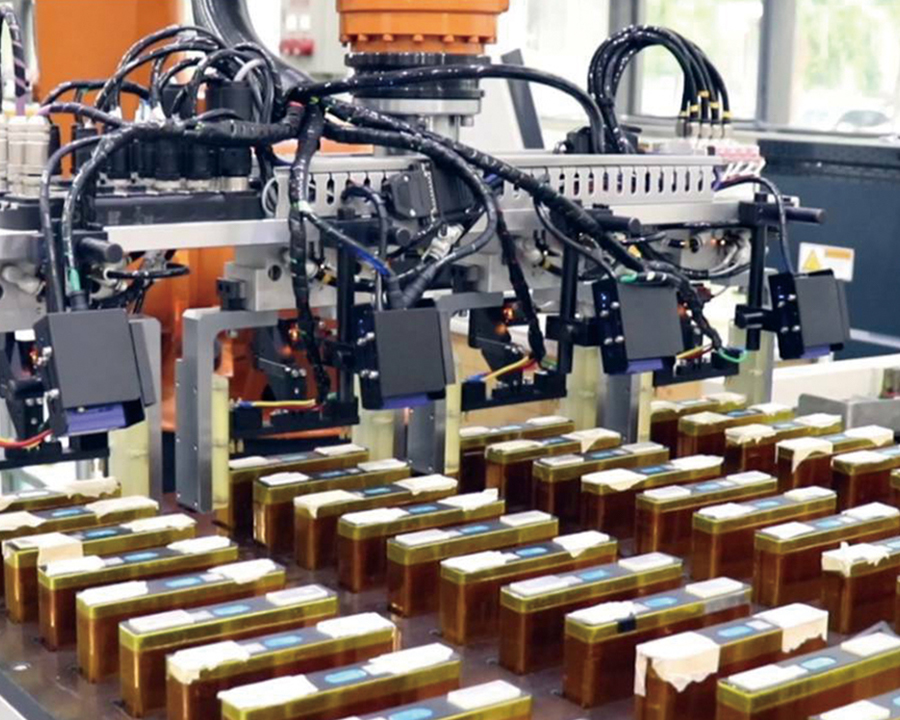

With the rapid development of new energy vehicles, automatic spot welding machines have also been widely used in the field of power battery manufacturing. The power battery module is composed of multiple battery cells connected by welding, which requires extremely high welding accuracy and reliability. Automatic spot welding machines can use advanced welding technologies such as laser spot welding to achieve high-precision welding of battery cell tabs, avoid battery short circuits and excessive contact resistance caused by poor welding, and ensure the performance and safety of power batteries.

5.2 Electronic and electrical industry

The products of the electronic and electrical industry are characterized by small size, high precision, and high integration, and the requirements for the precision and reliability of the welding process are extremely demanding. With its unique advantages, automatic spot welding machines occupy an important position in the welding production of the electronic and electrical industry.

In the welding of electronic components, such as resistors, capacitors, chips, etc. and circuit boards, automatic spot welding machines can use laser spot welding or precision resistance spot welding technology. Laser spot welding has the advantages of concentrated energy and small heat-affected zone, and can achieve high-precision welding of tiny solder joints without damaging surrounding components. For example, in the welding process of mobile phone chips, laser spot welding can accurately connect the chip pins with the pads on the circuit board, and the solder joint diameter can be controlled to tens of microns or even smaller, ensuring the normal operation of the chip and the stability of signal transmission. Precision resistance spot welding is suitable for welding some electronic components that require high solder joint strength. By accurately controlling the welding current, time and electrode pressure, high-quality solder joints can be formed to ensure reliable connection between components and circuit boards.

In the assembly welding of electrical products, such as the welding of the outer shells of refrigerators, air conditioners, washing machines, etc., automatic spot welding machines can realize automated mass production. Through the automated conveying and positioning mechanism, the various components of the electrical shell can be accurately conveyed to the welding position, and then the automatic spot welding machine can be used for rapid welding. The high-efficiency production capacity of the automatic spot welding machine can meet the needs of large-scale production of electrical products, and the stable welding quality also ensures the appearance and structural strength of the product.

In addition, in some special welding needs in the electronic and electrical industry, such as welding of dissimilar materials and welding of flexible circuit boards, the automatic spot welding machine can also achieve high-quality welding by adopting special welding processes and equipment configurations, providing strong support for the innovative design and manufacturing of electronic and electrical products.

5.3 Aerospace field

The aerospace field has reached the extreme requirements for product quality and reliability. As one of the key processes in the manufacture of aerospace parts, welding places extremely high requirements on the performance and precision of welding equipment. Automatic spot welding machines have been widely used in the aerospace field due to their high precision, high quality and high reliability.

English

English русский

русский عربى

عربى